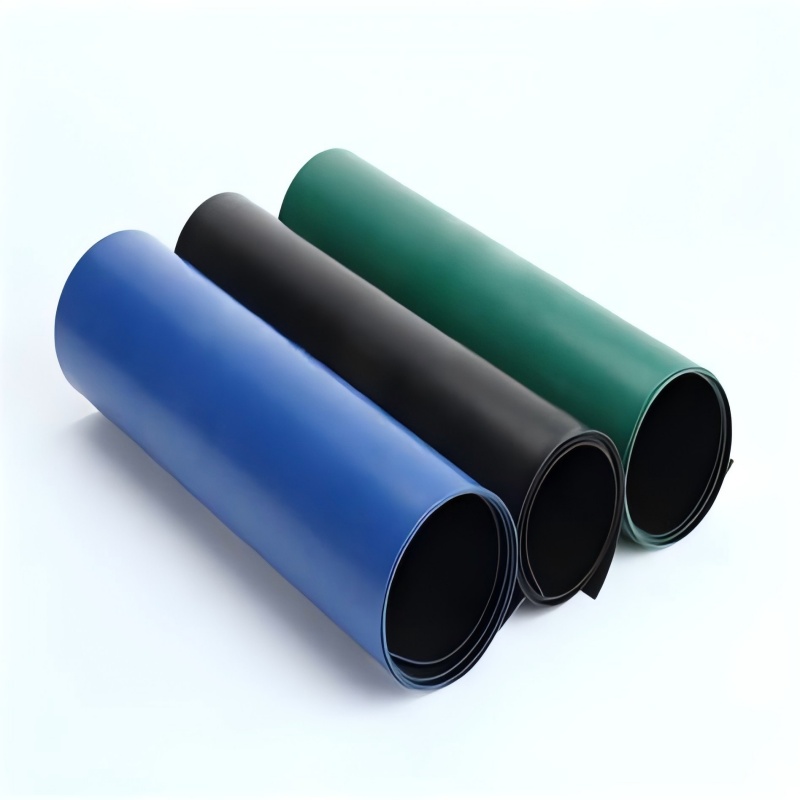

1mm HDPE Liner

1. Strong impermeability: The permeability coefficient is extremely low, almost impermeable, effectively blocking the leakage of water and harmful substances

2. Durable and anti manufacturing: acid and alkali corrosion resistance, anti-aging, good tensile and puncture resistance, suitable for complex environments

3. Convenient construction: The texture is flexible and easy to lay, which can fit the deformation of the foundation, and the splicing is simple and efficient

4. Environmental Economy: Environmentally friendly and non-toxic, with a long service life, and more cost-effective compared to traditional anti-seepage materials

Products Introduction:

1mm HDPE Liner (1mm high-density polyethylene anti-seepage film) is a homogeneous anti-seepage material made of high-quality high-density polyethylene (HDPE) resin through blow molding or rolling processes. Its core positioning is "an efficient barrier for medium and low pressure anti-seepage engineering". With the dense molecular structure of HDPE material, it achieves almost absolute anti-seepage effect. At the same time, the 1mm thickness design ensures anti-seepage performance and mechanical strength while considering flexibility and construction convenience. It is mainly used to solve problems such as liquid leakage, groundwater pollution, and water resource loss in water conservancy, environmental protection, and construction fields, providing an economical and reliable solution for medium and large-scale anti-seepage projects.

Different from thicker HDPE anti-seepage films (such as 1.5mm and 2mm), 1mm HDPE Liner achieves a "balance between performance and cost" in medium and low pressure scenarios (such as reservoirs, scenic lakes, and general landfills), meeting anti-seepage requirements while reducing material and construction costs; Compared to other anti-seepage films such as PVC and LDPE, it has more advantages in weather resistance, corrosion resistance, and service life, and is the mainstream choice for medium and low pressure anti-seepage engineering.

Product Features:

1. Ultimate anti-seepage and excellent barrier performance

The dense molecular structure formed by HDPE resin results in a permeability coefficient of ≤ 1 × 10 ⁻¹³ cm/s, far below the industry's anti-seepage standard (≤ 1 × 10 ⁻¹¹ cm/s), almost achieving absolute impermeability and effectively blocking the permeation and migration of various liquids such as rainwater, groundwater, sewage, and chemicals; A uniform thickness of 1mm ensures no pinholes or defects, and when combined with hot melt welding technology (welding strength ≥ 80% of substrate strength), can form a seamless anti-seepage system to eliminate the risk of joint leakage.

2. Durable and durable, with strong environmental adaptability

Excellent physical and chemical stability: tensile strength ≥ 18MPa, fracture elongation ≥ 600%, able to adapt to deformation caused by slight settlement of the foundation and temperature changes; Anti puncture strength ≥ 300N, able to resist gravel friction, mechanical compaction, and plant root puncture during construction; The acid and alkali resistance range covers pH values of 2-13, and it is resistant to UV aging (with a performance degradation of ≤ 10% after 5 years of outdoor exposure). Its service life can reach 15-20 years in complex environments such as saline alkali land, humid coastal areas, and chemical pollution.

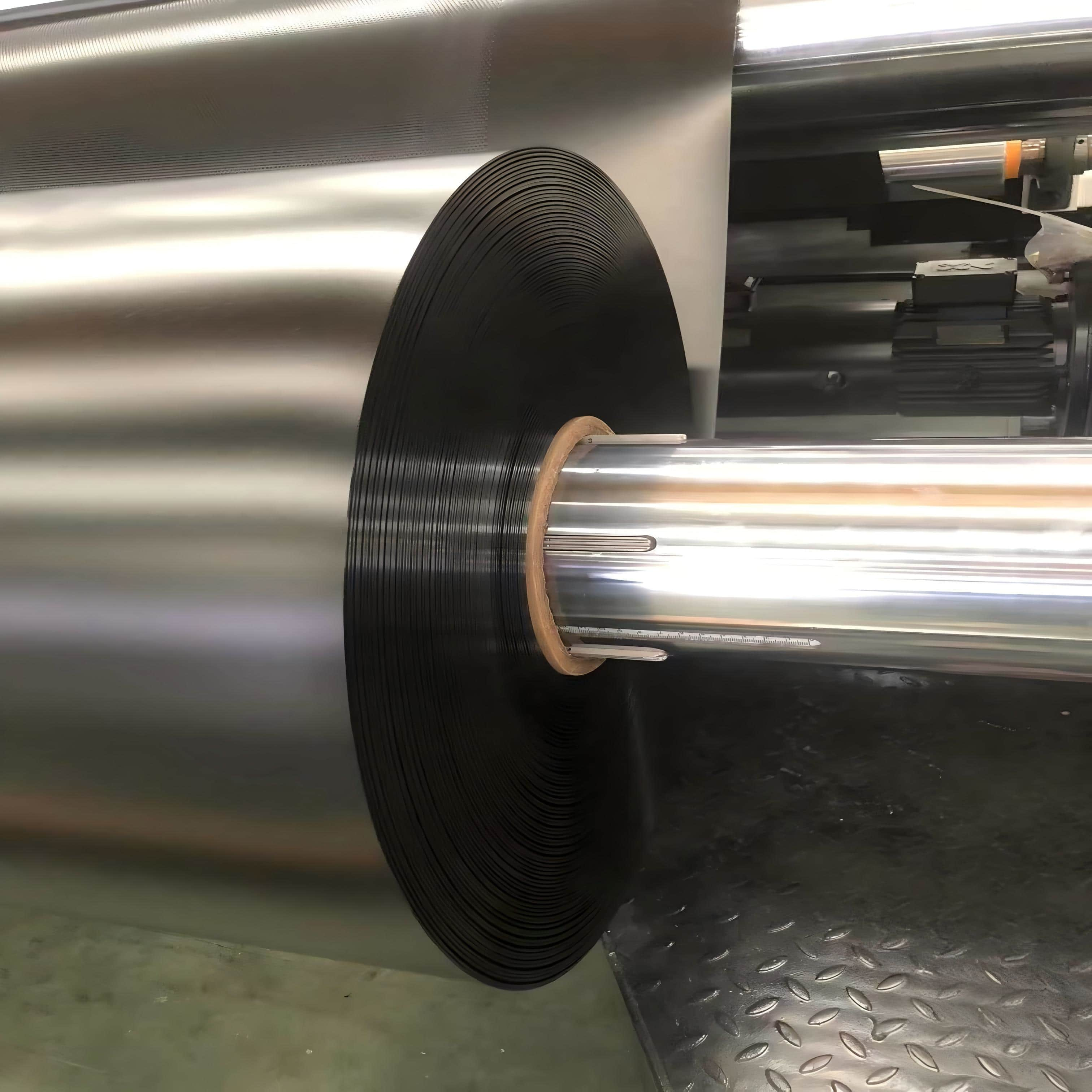

3. Flexible and easy to lay, efficient and convenient construction

The 1mm thickness endows the product with good flexibility, allowing it to naturally adhere to curved surfaces, irregular potholes, and structural corners, without any blind spots for seepage prevention; There are various specifications for single rolls (commonly 6m × 50m, 8m × 60m), and the weight of a single roll is light (6m × 50m roll weighs about 180kg), making it easy to transport and lay; Splicing can be completed using a hot air gun or automatic welding machine, with a welding speed of 3-5m/min and a manual laying efficiency of 200-300 ㎡/day, greatly reducing construction difficulty and project cost.

4. Environmental friendly economy with excellent full cycle value

The raw material is food grade HDPE resin, which is non-toxic, odorless, recyclable, and meets environmental protection requirements. It is suitable for scenarios with high environmental requirements such as drinking water tanks and landscape water bodies; Compared to traditional anti-seepage materials such as concrete and clay anti-seepage layers, the material cost is reduced by 40% -60%, the construction labor cost is reduced by more than 30%, and the maintenance frequency in the later stage is low (annual maintenance cost ≤ 1% of the total material price), resulting in significant economic benefits throughout the entire cycle.

5. Standardized compliance and wide engineering adaptability

The product complies with domestic and international standards such as GB/T 17643-2011 "Geosynthetic Materials - Polyethylene Geomembrane" and ASTM D4397, and provides third-party testing reports for each batch; Can be used in conjunction with other geotechnical materials such as geotextile (as a protective layer), drainage board, geogrid, etc., compatible with subsequent engineering processes such as concrete pouring and earthwork backfilling, and suitable for various medium and low pressure anti-seepage engineering scenarios.

Product Parameters:

Metric | ASTM | unit | Test value | Minimum test frequency | ||||||

test method | 0.75 mm | 1.00 mm | 1.25 mm | 1.50 mm | 2.00 mm | 2.50mm | 3.00 mm | |||

Minimum average thickness | D5199 | mm | 0.75 | 1 | 1.25 | 1.5 | 2 | 2.5 | 3 | Per volume |

Minimum value (any one of 10) | -10% | -10% | -10% | -10% | -10% | -10% | -10% | |||

minimum density | D 1505/D 792 | g/cm3 | 0.94 | 0.94 | 0.94 | 0.94 | 0.94 | 0.94 | 0.94 | 90,000 kg |

Minimum average tensile performance (1) | D638 Type IV | |||||||||

Breakage strength, | N/mm | 20 | 27 | 33 | 40 | 53 | 67 | 80 | 9,000 kg | |

yield strength | N/mm | 11 | 15 | 18 | 22 | 29 | 37 | 44 | ||

Strain extension, | % | 700 | 700 | 700 | 700 | 700 | 700 | 700 | ||

yield extension | % | 12 | 12 | 12 | 12 | 12 | 12 | 12 | ||

Minimum strength of right-angle tear | D 1004 | N | 93 | 125 | 156 | 187 | 249 | 311 | 374 | 20,000 kg |

Minimum puncture strength | D4833 | N | 240 | 320 | 400 | 480 | 640 | 800 | 960 | 20,000 kg |

Constant tensile load stress cracking (2) | D5397 | hour | 300 | 300 | 300 | 300 | 300 | 300 | 300 | Based on GRI GM-10 |

Carbon black content | D 1603(3) | % | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 9,000 kg |

Carbon black dispersion | D5596 | Note (4) | Note (4) | Note (4) | Note (4) | Note (4) | Note (4) | Note (4) | 20,000 kg | |

Oxygen induction time (OIT) (5) | 90,000 kg | |||||||||

(a) Standard OIT | D3895 | minute | 100 | 100 | 100 | 100 | 100 | 100 | 100 | |

(b) high-handed OIT | D5885 | minute | 400 | 400 | 400 | 400 | 400 | 400 | 400 | |

85℃ Oven aging (minimum average) (5)(6) | Per formula | |||||||||

(A) Standard OIT is retained after 90 days | D 5721 | % | 55 | 55 | 55 | 55 | 55 | 55 | 55 | |

(B) High voltage OIT is retained for 90 days | D 3895 D5885 | % | 80 | 80 | 80 | 80 | 80 | 80 | 80 | |

Ultraviolet resistance (7) | Per formula | |||||||||

(a) standard OIT | D3895 | Note (8) 50 | ||||||||

(b) Retention of high pressure OIT after 1600 hours (9) | D5885 | % | ||||||||

Product Applications:

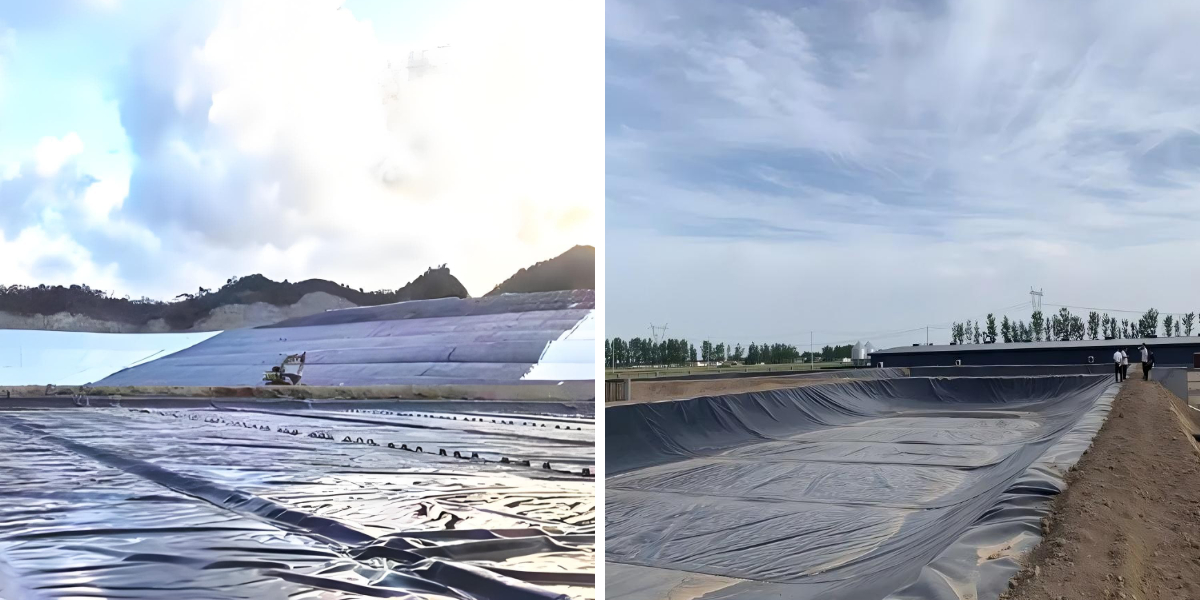

1. Water conservancy and water engineering

Reservoir/Artificial Lake: Installed at the bottom and slopes of drinking water reservoirs, agricultural irrigation ponds, and landscape artificial lakes to prevent water leakage, maintain stable water levels, and adapt to rural safe drinking water projects and park landscape lake construction projects.

Water conveyance channels/fish ponds: anti-seepage liners used for irrigation channels in farmland to reduce water resource leakage losses; Or used for bottom anti-seepage of fish ponds and shrimp ponds, to prevent water leakage and groundwater pollution in aquaculture, suitable for agricultural water conservancy renovation and aquaculture projects.

2. Environmental Protection and Pollution Prevention Engineering

Landfill site: As a secondary anti-seepage layer or sealing cover layer for domestic waste landfill sites, it prevents the infiltration of leachate into the soil and groundwater, and is used in conjunction with geotextile protection layer, suitable for small and medium-sized landfill projects.

Sewage treatment/chemical anti-seepage: used as anti-seepage liners for sedimentation tanks in sewage treatment plants and waste liquid storage tanks in chemical parks, to prevent sewage and chemical waste liquid from leaking and polluting the surrounding environment, and to adapt to industrial environmental protection anti-seepage projects.

3. Construction and Municipal Engineering

Basement/garage moisture-proof: laid between the basement floor, the outer side of the wall, and the soil to form a waterproof barrier, preventing groundwater from seeping into the interior, avoiding wall moisture and mold, and suitable for residential and commercial building basement waterproofing projects.

Roof greening/water features: used as an anti-seepage layer for roof greening and a lining for landscape water features, to prevent water seepage from greening and water features from damaging the building roof structure, suitable for urban building roof greening and commercial complex landscape water features projects.

4. Mining and Agricultural Engineering

Mine tailings pond: As an anti-seepage liner for mine tailings pond, it prevents tailings leachate from polluting soil and groundwater, protects the surrounding ecological environment, and is suitable for safety protection projects of small and medium-sized mine tailings pond.

Saline alkali land improvement: It is laid underground in the saline alkali land improvement area to form a barrier layer, prevent the rise of underground saline alkali water, cooperate with the salt discharge system, improve soil quality, and adapt to agricultural saline alkali land treatment projects.

1mm HDPE Liner, with its core advantages of "ultimate anti-seepage barrier, durable and stable resistance, flexible and easy to lay, efficient, environmentally friendly and economical", accurately solves the core pain points of "high leakage risk, poor environmental adaptability, and high construction cost" in medium and low pressure anti-seepage engineering, and is the preferred material for medium and large-scale anti-seepage projects.