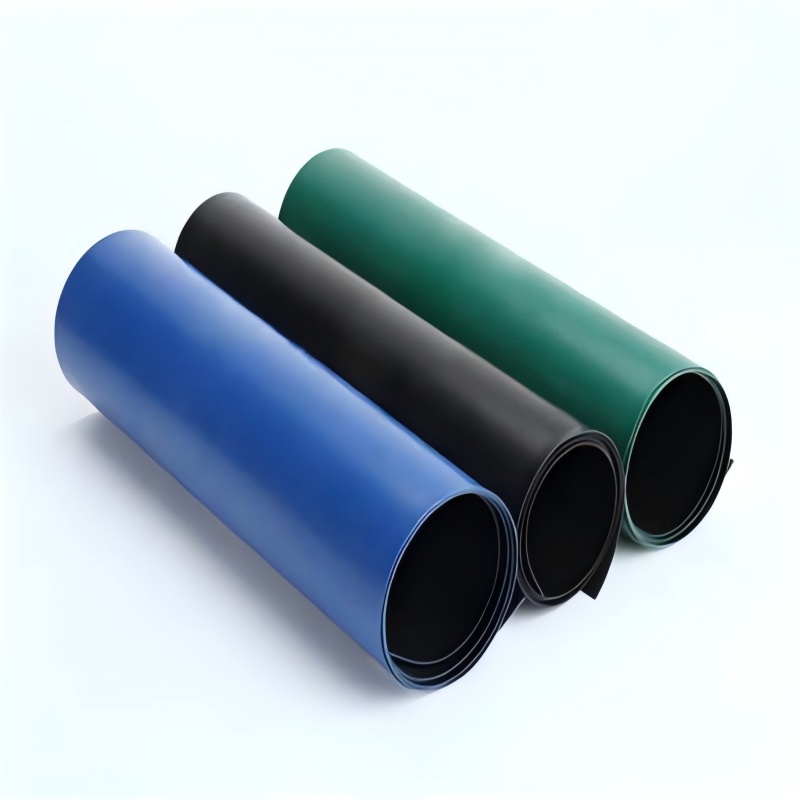

HDPE Liner Material

1. Outstanding anti-seepage performance: Made of high-density polyethylene as raw material, with a tight molecular structure, it can effectively block the infiltration of moisture and harmful substances, forming a reliable anti-seepage barrier in various engineering projects.

2. Strong weather resistance and corrosion resistance: It can resist UV aging and withstand corrosion from acids, bases, organic solvents, etc., maintaining stable performance in complex environments and extending the service life of the project.

3. Efficient and worry free construction: The material is lightweight and flexible, easy to transport, lay and weld, with high joint strength, which can shorten the construction period and reduce the overall cost of the project.

4. Excellent strength and adaptability: It has high tensile strength and puncture resistance, can withstand external impact and soil pressure, adapt to complex terrain, and ensure the integrity of the anti-seepage structure.

Products Introduction:

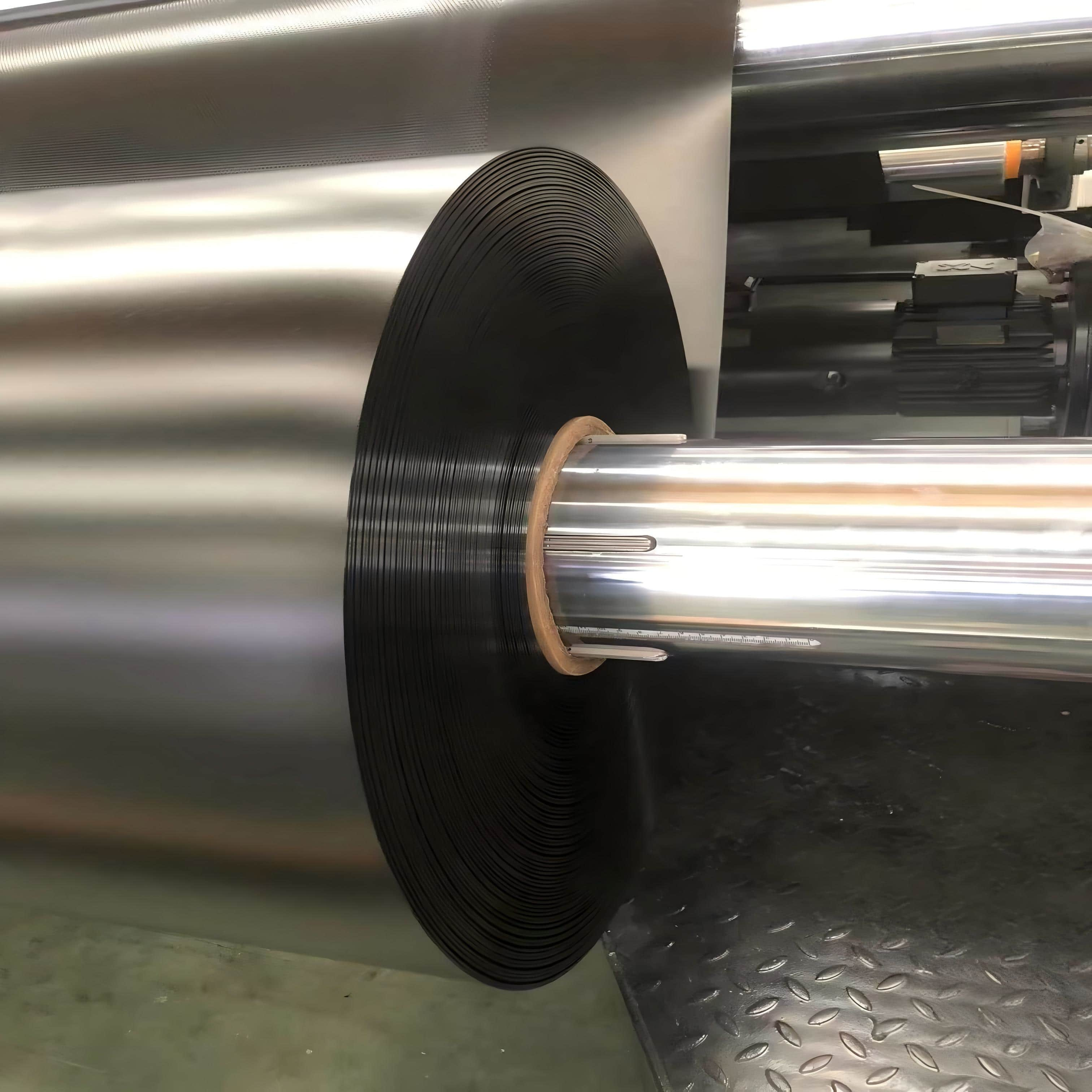

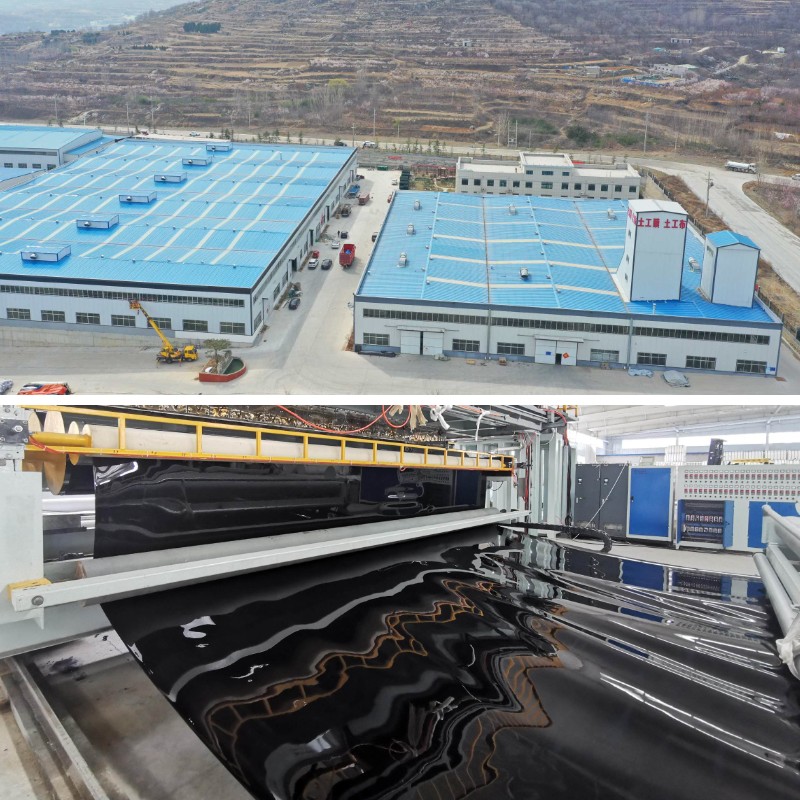

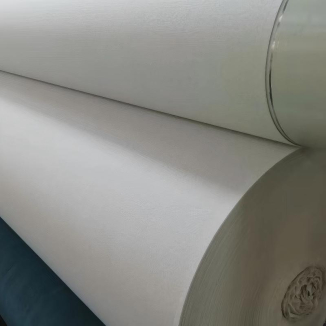

HDPE Liner Material geomembrane is a flexible anti-seepage material made from high-density polyethylene (HDPE) as the core material and processed by special technology. It processes HDPE resin into thin film products with a certain thickness and ductility through advanced technologies such as extrusion molding, combining chemical stability and physical and mechanical properties. As a commonly used anti-seepage solution in modern engineering construction, its design concept focuses on "efficient barrier, durable", which can meet the basic needs of various projects for anti-seepage and adapt to complex working conditions in different environments. It is currently one of the widely used and well reputed materials in the field of anti-seepage engineering.

Product Features:

1. Excellent anti-seepage ability: The molecular structure of HDPE is tightly arranged, forming a natural anti-seepage barrier, which has a significant anti-seepage effect on moisture, liquids, and various chemical media. After testing, its anti-seepage coefficient can reach the level of 10 ⁻¹¹ cm/s, far superior to traditional anti-seepage materials, and can effectively avoid engineering hazards caused by leakage problems.

2. Excellent weather resistance and corrosion resistance: It has excellent resistance to UV aging and is not prone to cracking, degradation, and other phenomena when exposed to outdoor environments for a long time; At the same time, it has strong tolerance to corrosive substances such as acids, bases, salts, and organic solvents, and can be stably used in highly corrosive scenarios such as chemical and mining industries, greatly extending the service life of the project.

3. Reliable physical and mechanical properties: It has high tensile strength and elongation at break, and can withstand the tensile stress caused by soil pressure, external impact, and temperature changes; Outstanding puncture resistance, able to resist the puncture damage of sharp objects such as stones and tree roots, ensuring the integrity of the anti-seepage structure.

4. Convenient construction and maintenance: The product is lightweight and flexible, and is not easily damaged during transportation. It can adapt to the curvature and slope of different terrains when laid; Connected by hot melt welding and other methods, the joint strength is high, the sealing is good, and the construction efficiency is high; Post maintenance is simple and can be quickly repaired in case of local damage, reducing maintenance costs.

Product Parameters:

Metric | ASTM | unit | Test value | Minimum test frequency | ||||||

test method | 0.75 mm | 1.00 mm | 1.25 mm | 1.50 mm | 2.00 mm | 2.50mm | 3.00 mm | |||

Minimum average thickness | D5199 | mm | 0.75 | 1 | 1.25 | 1.5 | 2 | 2.5 | 3 | Per volume |

Minimum value (any one of 10) | -10% | -10% | -10% | -10% | -10% | -10% | -10% | |||

minimum density | D 1505/D 792 | g/cm3 | 0.94 | 0.94 | 0.94 | 0.94 | 0.94 | 0.94 | 0.94 | 90,000 kg |

Minimum average tensile performance (1) | D638 Type IV | |||||||||

Breakage strength, | N/mm | 20 | 27 | 33 | 40 | 53 | 67 | 80 | 9,000 kg | |

yield strength | N/mm | 11 | 15 | 18 | 22 | 29 | 37 | 44 | ||

Strain extension, | % | 700 | 700 | 700 | 700 | 700 | 700 | 700 | ||

yield extension | % | 12 | 12 | 12 | 12 | 12 | 12 | 12 | ||

Minimum strength of right-angle tear | D 1004 | N | 93 | 125 | 156 | 187 | 249 | 311 | 374 | 20,000 kg |

Minimum puncture strength | D4833 | N | 240 | 320 | 400 | 480 | 640 | 800 | 960 | 20,000 kg |

Constant tensile load stress cracking (2) | D5397 | hour | 300 | 300 | 300 | 300 | 300 | 300 | 300 | Based on GRI GM-10 |

Carbon black content | D 1603(3) | % | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 9,000 kg |

Carbon black dispersion | D5596 | Note (4) | Note (4) | Note (4) | Note (4) | Note (4) | Note (4) | Note (4) | 20,000 kg | |

Oxygen induction time (OIT) (5) | 90,000 kg | |||||||||

(a) Standard OIT | D3895 | minute | 100 | 100 | 100 | 100 | 100 | 100 | 100 | |

(b) high-handed OIT | D5885 | minute | 400 | 400 | 400 | 400 | 400 | 400 | 400 | |

85℃ Oven aging (minimum average) (5)(6) | Per formula | |||||||||

(A) Standard OIT is retained after 90 days | D 5721 | % | 55 | 55 | 55 | 55 | 55 | 55 | 55 | |

(B) High voltage OIT is retained for 90 days | D 3895 D5885 | % | 80 | 80 | 80 | 80 | 80 | 80 | 80 | |

Ultraviolet resistance (7) | Per formula | |||||||||

(a) standard OIT | D3895 | Note (8) 50 | ||||||||

(b) Retention of high pressure OIT after 1600 hours (9) | D5885 | % | ||||||||

Product Applications:

1. Environmental engineering: In landfills, it can be used for bottom and surrounding anti-seepage to prevent leachate leakage from polluting soil and groundwater; In facilities such as sedimentation tanks and regulating tanks in sewage treatment plants, they play a role in blocking the infiltration of sewage.

2. Water conservancy and municipal engineering: suitable for anti-seepage of artificial lakes, reservoirs, channels and other water conservancy facilities, reducing water resource loss; In the construction of anti-seepage layers in underground pipe galleries and subway projects, it can effectively prevent groundwater intrusion.

3. Mining and chemical engineering: In the mining industry, it can be used for anti-seepage of tailings ponds and heap leaching pools to prevent leakage of slurry and harmful components; The storage tank area, reaction tank and other areas in the chemical industry can achieve safe and anti-seepage through their anti-corrosion properties.

4. Agriculture and landscape engineering: applied in water reservoirs and channels for agricultural irrigation to reduce water resource infiltration and waste; In landscape engineering, scenes such as artificial wetlands and water feature creation ensure the stability of landscape water bodies through anti-seepage measures.

HDPE Liner Material geomembrane has become an ideal choice for anti-seepage in various engineering projects due to its outstanding anti-seepage performance, excellent weather resistance and corrosion resistance, reliable physical and mechanical performance, and convenient construction and maintenance advantages. It can not only build solid anti-seepage barriers in multiple fields such as environmental protection, water conservancy, mining, etc., reducing the risk of engineering leakage, but also bring long-term economic and environmental benefits to the project by extending its service life and reducing maintenance costs. Whether it is complex industrial scenarios or daily municipal and landscape engineering, this product can meet anti-seepage requirements with stable performance, making it a practical and reliable engineering material.