Geo Fabric Waterproofing

1. Efficient anti-seepage: The dense structure blocks the water infiltration path, effectively intercepting groundwater and rainwater, and preventing leakage

2. Weather resistance and damage resistance: resistant to ultraviolet radiation, acid and alkali corrosion, and not easily aged or damaged for outdoor or buried use

3. Flexible fit: can fit irregular base surfaces, adapt to structural micro deformation, and have no blind spots for anti-seepage

4. Convenient construction: Lightweight and easy to cut and lay, compatible with various fixing methods such as hot melt and adhesive, high efficiency

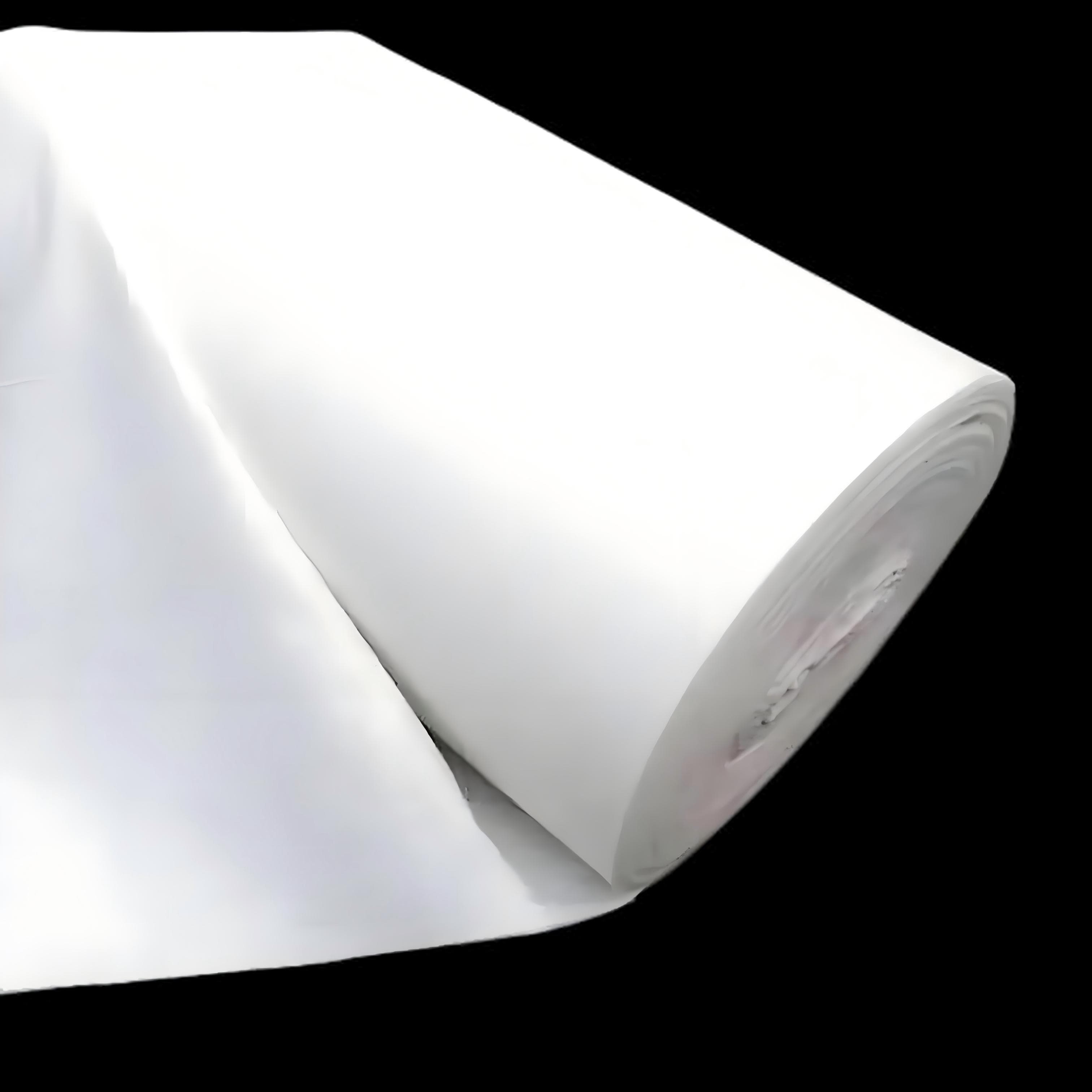

Products Introduction:

Geo Fabric Waterproofing is a type of functional anti-seepage material made from high molecular weight polymers (such as polyethylene PE, polyvinyl chloride PVC, and ethylene vinyl acetate EVA) as substrates, reinforced or coated with composite geotextiles. Its core positioning is "integrated barrier for engineering waterproofing and protection". It achieves efficient anti-seepage through dense polymer substrates, while enhancing mechanical strength and weather resistance through composite geotextile layers. It is mainly used to solve problems such as groundwater leakage, rainwater intrusion, and liquid infiltration pollution in engineering, providing long-term waterproof protection solutions for fields such as water conservancy, construction, and environmental protection.

Product Features:

1. Efficient anti-seepage and excellent barrier performance

Using high-density polyethylene (HDPE) or PVC as anti-seepage substrates, with a permeability coefficient of ≤ 1 × 10 ⁻¹¹ cm/s, much lower than that of ordinary geotextiles (1 × 10 ⁻³ -1 × 10 ⁻⁴ cm/s), it can effectively block the infiltration path of liquids such as groundwater, rainwater, and sewage; Part of the composite geotextile models form a seamless anti-seepage layer through hot melt welding, with a welding strength of ≥ 80% of the base material strength, further eliminating the risk of joint leakage and adapting to engineering scenarios with high anti-seepage requirements.

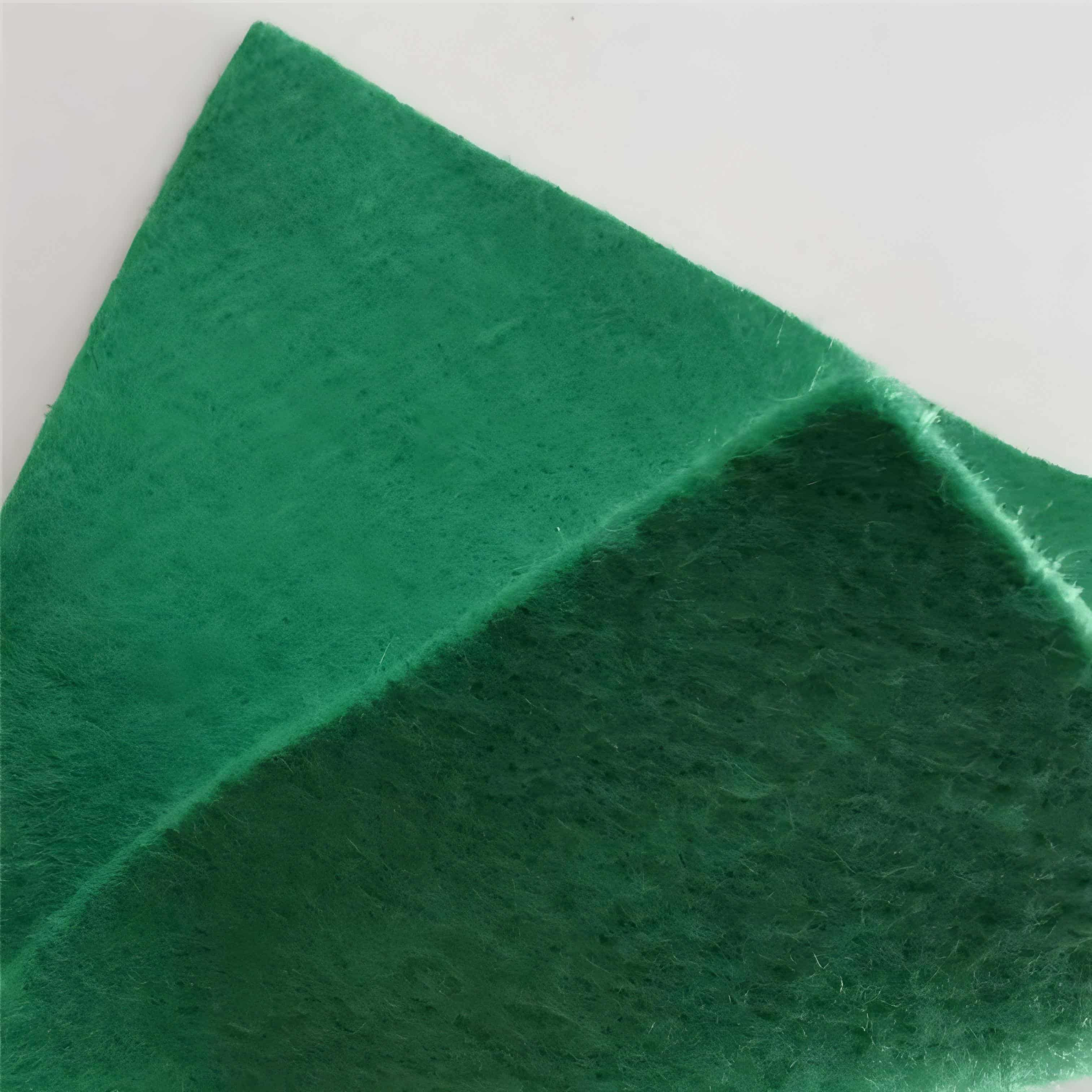

2. Composite reinforcement, reliable mechanical properties

The composite needle punched non-woven geotextile or woven geotextile reinforcement layer on the surface of the substrate has a longitudinal and transverse fracture strength of 15-50kN/m, a tear resistance strength of ≥ 3kN, and excellent puncture resistance (≥ 300N). It can resist tensile deformation caused by gravel friction, mechanical compaction, and uneven soil settlement during construction, avoid substrate damage affecting the anti-seepage effect, and ensure long-term stability of the waterproof structure.

3. Weather resistant and corrosion-resistant, with wide environmental adaptability

The substrate can work stably in the extreme temperature range of -30 ℃ to 70 ℃ after anti ultraviolet (UV) and anti-aging treatment; Resistant to acid-base solutions (pH 3-11), salt spray, and industrial wastewater erosion, the service life can reach 10-20 years (buried) in complex conditions such as saline alkali land, humid coastal environments, and chemical contaminated sites, and can be exposed for 5-8 years, reducing the cost of later waterproofing maintenance.

4. Flexible and snug fit, convenient and efficient construction

The product has good flexibility, with a fracture elongation rate of ≥ 200% (PE substrate), and can adhere to curved base surfaces, irregular slopes, and structural corners without waterproof blind spots; The length of a single roll can reach 50-100m, and the width can be selected from 2-6m. It supports various construction methods such as hot melt welding, adhesive bonding, and mechanical fixation. It can be laid manually or with small welding equipment, with a construction efficiency of 300-500 ㎡/day, suitable for different construction conditions.

5. Integrated protection, compatible with multiple engineering processes

The composite geotextile reinforcement layer has both protective functions and can replace individual protective layer materials, reducing the number of layers in the engineering structure; Strong compatibility with other engineering materials such as concrete, sand and gravel, geogrids, etc., it can be directly laid on the surface of structures such as foundations, walls, slopes, etc., without affecting the subsequent construction process (such as backfilling and pouring), and is suitable for the needs of "waterproofing+protection" composite engineering.

Product Parameters:

project | metric | ||||||||||

Nominal strength/(kN/m) | |||||||||||

6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |||

1 | Longitudinal and transverse tensile strength / (kN/m) ≥ | 6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |

2 | Maximum elongation at maximum load in longitudinal and transverse directions/% | 30~80 | |||||||||

3 | CBR top penetration strength /kN ≥ | 0.9 | 1.6 | 1.9 | 2.9 | 3.9 | 5.3 | 6.4 | 7.9 | 8.5 | |

4 | Longitudinal and transverse tearing strength /kN | 0.15 | 0.22 | 0.29 | 0.43 | 0.57 | 0.71 | 0.83 | 1.1 | 1.25 | |

5 | Equivalent aperture O.90(O95)/mm | 0.05~0.30 | |||||||||

6 | Vertical permeability coefficient/(cm/s) | K× (10-¹~10-), where K=1.0~9.9 | |||||||||

7 | Width deviation rate /% ≥ | -0.5 | |||||||||

8 | Unit area mass deviation rate /% ≥ | -5 | |||||||||

9 | Thickness deviation rate /% ≥ | -10 | |||||||||

10 | Thickness coefficient of variation (CV)/% ≤ | 10 | |||||||||

11 | Dynamic perforation | Puncture hole diameter/mm ≤ | 37 | 33 | 27 | 20 | 17 | 14 | 11 | 9 | 7 |

12 | Longitudinal and transverse fracture strength (grab method)/kN ≥ | 0.3 | 0.5 | 0.7 | 1.1 | 1.4 | 1.9 | 2.4 | 3 | 3.5 | |

13 | Ultraviolet resistance (Xenon arc lamp method) | Longitudinal and transverse strength retention rate% ≥ | 70 | ||||||||

14 | Ultraviolet resistance (fluorescence UV lamp method) | Longitudinal and transverse strength retention rate% ≥ | 80 | ||||||||

Product Applications:

1. Water conservancy and water engineering

Dam/reservoir anti-seepage: laid on the upstream slope of the dam or the bottom of the reservoir to block water leakage and reduce water resource loss; Used in conjunction with geotextile filter layer to prevent soil particle loss and damage to the anti-seepage layer, suitable for small and medium-sized reservoir reinforcement and river flood control embankment seepage projects.

Artificial Lake/Reservoir: Used for waterproofing the bottom and slopes of artificial lakes, landscape reservoirs, and agricultural reservoirs to prevent water leakage, maintain stable water levels, and adapt to the construction of park landscape lakes and agricultural reservoirs.

2. Construction and Underground Engineering

Basement waterproofing: laid between the outer side of the basement wall and the foundation soil, forming a waterproof barrier to prevent groundwater from seeping into the interior, avoiding wall moisture and mold growth, and suitable for residential and commercial building basement waterproofing projects.

Underground pipe gallery/tunnel: used for waterproofing the outer walls of underground comprehensive pipe galleries and tunnels, resisting soil water and groundwater erosion, protecting the structure and internal pipeline safety of pipe galleries, and adapting to urban underground pipe gallery construction projects.

3. Environmental Protection and Pollution Prevention Engineering

Landfill site: As an anti-seepage material for landfill liner and sealing cover layer, it blocks the infiltration of leachate into soil and groundwater, preventing environmental pollution; The composite geotextile layer can protect the anti-seepage membrane from garbage puncture and is suitable for domestic and industrial waste landfill projects.

Chemical site anti-seepage: used for waterproofing sedimentation tanks and waste liquid storage tanks in chemical parks and sewage treatment plants, to prevent chemical waste liquid leakage from polluting soil and groundwater, and to adapt to industrial environmental protection anti-seepage projects.

4. Transportation and Municipal Engineering

Road subgrade waterproofing: laid at the base or slope of the road to prevent groundwater from rising and softening the subgrade, and to prevent the pavement from turning over and cracking. It is suitable for waterproofing protection of highway and high-grade highway subgrade.

Municipal sewage pipe channel: used for waterproofing the inner or outer walls of municipal sewage pipe channels, preventing sewage leakage and polluting the surrounding soil, while resisting soil water erosion of the pipe channel structure, and adapting to municipal sewage pipe network renovation projects.

Geo Fabric Waterproofing, with its core advantages of "efficient anti-seepage and barrier, composite reinforcement and durability, flexibility and easy adaptation, and integrated economic protection", accurately solves the core pain points of "waterproof failure, complex construction, and poor environmental adaptability" in various fields of engineering. It is a professional waterproof geotechnical material that combines reliability and cost-effectiveness.

Compared to traditional waterproofing membranes, it not only achieves dual protection of waterproofing and protection through a composite structure of "anti-seepage substrate+geotextile reinforcement", but also reduces the difficulty of waterproofing construction on complex substrates with excellent flexibility and construction convenience; Compared to a single geomembrane, the use of a reinforcement layer enhances its resistance to damage and service life. From dam anti-seepage in water conservancy engineering to basement waterproofing in construction engineering, from pollution isolation in environmental protection engineering to roadbed protection in municipal engineering, waterproof geotextiles provide solid guarantees for the safety of engineering structures and the environment with efficient and reliable anti-seepage performance, becoming an indispensable key material in modern waterproofing engineering.