Geofabrics Bunnings

1. High strength: Good tensile and tear resistance, able to withstand large loads.

2. Durability: corrosion resistance, UV resistance, aging resistance, long service life.

3. Permeability: allows water to pass through while preventing soil particle loss, playing a filtering role.

4. Convenient construction: lightweight, easy to cut and lay, saving labor and time costs.

5. Environmental friendliness: Some materials are recyclable, reducing pollution to the environment.

6. Economy: Compared to traditional materials such as sand and gravel, the cost is lower and the effect is better.

Product Introduction:

Geofabrics Bunnings are permeable geosynthetic material made from synthetic fibers such as polyester (PET) and polypropylene (PP) through needle punching, weaving, or thermal bonding processes. The finished product is in the form of cloth, with standard specifications of 4-6 meters in width and 50-100 meters in length. Some products can have a width of up to 9 meters, and the unit area mass covers 100-1000g/m ². According to different processes, geotextiles are divided into two categories:

Woven geotextile: formed with regular pores through weaving process, structurally stable, and high tensile strength.

Non woven long filament geotextile: using needle punching or thermal bonding technology, the fibers are randomly arranged, and the permeability is better.

Functional Features

1. Isolation function

Block materials with different physical properties (such as soil and concrete, sand and asphalt), prevent mixing, and maintain structural stability.

2. Reinforcement and strengthening

By utilizing the frictional force between fibers and soil, the tensile strength and deformation resistance of the soil are enhanced, thereby improving the bearing capacity of weak foundations.

3. Protection and stress dispersion

Buffer external forces such as water flow erosion and vehicle loads, decompose concentrated stress into uniform distribution, and protect the soil from damage.

4. Closure and puncture prevention

Combined with geomembrane, it forms a waterproof and anti-seepage layer, preventing sharp objects from piercing and improving the anti-seepage effect.

5. Thermal insulation and antifreeze

In cold regions, covering the roadbed with geotextile can reduce settlement caused by permafrost melting and ensure road smoothness.

Product Parameters:

project | metric | ||||||||||

Nominal strength/(kN/m) | |||||||||||

6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |||

1 | Longitudinal and transverse tensile strength / (kN/m) ≥ | 6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |

2 | Maximum elongation at maximum load in longitudinal and transverse directions/% | 30~80 | |||||||||

3 | CBR top penetration strength /kN ≥ | 0.9 | 1.6 | 1.9 | 2.9 | 3.9 | 5.3 | 6.4 | 7.9 | 8.5 | |

4 | Longitudinal and transverse tearing strength /kN | 0.15 | 0.22 | 0.29 | 0.43 | 0.57 | 0.71 | 0.83 | 1.1 | 1.25 | |

5 | Equivalent aperture O.90(O95)/mm | 0.05~0.30 | |||||||||

6 | Vertical permeability coefficient/(cm/s) | K× (10-¹~10-), where K=1.0~9.9 | |||||||||

7 | Width deviation rate /% ≥ | -0.5 | |||||||||

8 | Unit area mass deviation rate /% ≥ | -5 | |||||||||

9 | Thickness deviation rate /% ≥ | -10 | |||||||||

10 | Thickness coefficient of variation (CV)/% ≤ | 10 | |||||||||

11 | Dynamic perforation | Puncture hole diameter/mm ≤ | 37 | 33 | 27 | 20 | 17 | 14 | 11 | 9 | 7 |

12 | Longitudinal and transverse fracture strength (grab method)/kN ≥ | 0.3 | 0.5 | 0.7 | 1.1 | 1.4 | 1.9 | 2.4 | 3 | 3.5 | |

13 | Ultraviolet resistance (Xenon arc lamp method) | Longitudinal and transverse strength retention rate% ≥ | 70 | ||||||||

14 | Ultraviolet resistance (fluorescence UV lamp method) | Longitudinal and transverse strength retention rate% ≥ | 80 | ||||||||

Product Applications:

1. Transportation Engineering

Highway/Railway: roadbed reinforcement, slope protection, crack repair (to prevent reflection cracks), soft foundation treatment.

Airport: Runway foundation reinforcement to reduce uneven settlement.

2. Water conservancy engineering

Embankment/Slope Protection: Anti erosion and anti filtration drainage, such as the Three Gorges Dam Slope Protection Project.

Water well/relief well: filter material to prevent sediment blockage.

Tunnel: Eliminate surrounding seepage and reduce external water pressure on the lining.

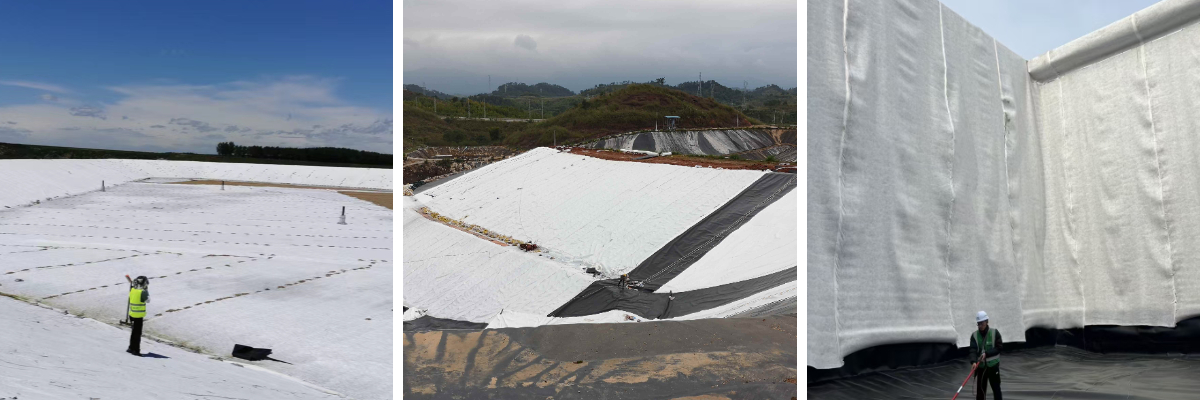

3. Environmental Protection Engineering

Landfill site: bottom anti-seepage system, leachate collection layer.

Wastewater treatment: The filtration tank and filter layer are used to improve treatment efficiency.

4. Municipal Administration and Architecture

Artificial Lake/Landscape Engineering: Bottom Waterproofing and Shape Support.

High rise buildings: foundation drainage to reduce pore water pressure.

5. Special Scenarios

Swamp area: Strengthen the foundation and enhance the bearing capacity when building roads.

Coastal mudflat: in the reclamation project, seawater and fill shall be separated to prevent salinization.

Geotextile, as a multifunctional geotechnical material, plays an irreplaceable role in modern engineering construction due to its high strength, permeability, durability, and economy. Geotextiles can provide efficient and reliable solutions for reinforcing foundations, drainage and anti-seepage, and environmental protection.