4 oz Geotextile Fabric

1. Superior technical performance: It can simultaneously achieve multiple functions such as isolation, reinforcement, drainage, filtration, and protection, which is incomparable to traditional materials.

2. High economic benefits: Low material costs, simple and fast construction, can save a lot of labor, machinery and material costs, shorten the construction period, and have low overall costs.

3. Good engineering quality: It can effectively improve the stability, durability, and safety of the project, and reduce problems such as uneven settlement.

4. Environmental protection: It reduces the damage to the environment caused by the extraction of natural materials and meets the requirements of sustainable development.

Product Introduction:

4 oz Geotextile Fabric is a new type of geotechnical material made from synthetic fibers (such as polyester, polypropylene, nylon, etc.) or natural fibers, and is a permeable geosynthetic material made through processes such as needle punching, weaving, thermal bonding, and chemical bonding. It is not a traditional "fabric", but a functional material specifically designed to solve problems such as filtration, drainage, isolation, and reinforcement in geotechnical engineering, playing a key role in fields such as water conservancy, transportation, construction, and environmental protection.

Core Features

The characteristics of geotextile are determined by its raw materials and processes, and can be summarized into the following five points:

1. High permeability: Rapid water infiltration is achieved through the pores between fibers (usually with a porosity of 70% -90%), while blocking soil particles - for example, the equivalent pore size of needle punched geotextile can be controlled at 0.02-0.2mm, which can not only allow rainwater and groundwater to be discharged smoothly, but also prevent sand loss.

2. Excellent mechanical properties: The tensile strength of synthetic fiber geotextiles can reach 10-50kN/m (far exceeding natural fibers), with excellent tear and puncture resistance, and can withstand uneven settlement and external impact in geotechnical engineering (such as vehicle loads and water flow erosion).

3. Environmental erosion resistance: Synthetic fibers (especially polyester) have strong resistance to acid and alkali (stable within the pH range of 3-11), salt spray, and microorganisms (such as mold and bacteria). They are not easily decomposed or degraded in complex environments such as soil, groundwater, and seawater, and have a service life of up to 20-50 years (depending on the usage scenario).

4. Flexibility and adaptability: Geotextile has a soft texture and can be folded and cut freely. It can tightly adhere to irregular rock and soil surfaces (such as steep slopes and foundation pit sidewalls), avoiding engineering hazards caused by interface mismatch (such as water leakage and soil uplift).

5. Lightweight and easy to construct: The unit weight of geotextile is usually 100-800g/㎡, and the length of each roll can reach 50-100m, with low transportation costs; No complex equipment is required during construction, only splicing (sewing, thermal bonding or chemical bonding) is needed, which is much more efficient than traditional materials such as sand and gravel filter layers.

Product Parameters:

project | metric | ||||||||||

Nominal strength/(kN/m) | |||||||||||

6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |||

1 | Longitudinal and transverse tensile strength / (kN/m) ≥ | 6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |

2 | Maximum elongation at maximum load in longitudinal and transverse directions/% | 30~80 | |||||||||

3 | CBR top penetration strength /kN ≥ | 0.9 | 1.6 | 1.9 | 2.9 | 3.9 | 5.3 | 6.4 | 7.9 | 8.5 | |

4 | Longitudinal and transverse tearing strength /kN | 0.15 | 0.22 | 0.29 | 0.43 | 0.57 | 0.71 | 0.83 | 1.1 | 1.25 | |

5 | Equivalent aperture O.90(O95)/mm | 0.05~0.30 | |||||||||

6 | Vertical permeability coefficient/(cm/s) | K× (10-¹~10-), where K=1.0~9.9 | |||||||||

7 | Width deviation rate /% ≥ | -0.5 | |||||||||

8 | Unit area mass deviation rate /% ≥ | -5 | |||||||||

9 | Thickness deviation rate /% ≥ | -10 | |||||||||

10 | Thickness coefficient of variation (CV)/% ≤ | 10 | |||||||||

11 | Dynamic perforation | Puncture hole diameter/mm ≤ | 37 | 33 | 27 | 20 | 17 | 14 | 11 | 9 | 7 |

12 | Longitudinal and transverse fracture strength (grab method)/kN ≥ | 0.3 | 0.5 | 0.7 | 1.1 | 1.4 | 1.9 | 2.4 | 3 | 3.5 | |

13 | Ultraviolet resistance (Xenon arc lamp method) | Longitudinal and transverse strength retention rate% ≥ | 70 | ||||||||

14 | Ultraviolet resistance (fluorescence UV lamp method) | Longitudinal and transverse strength retention rate% ≥ | 80 | ||||||||

Product Applications:

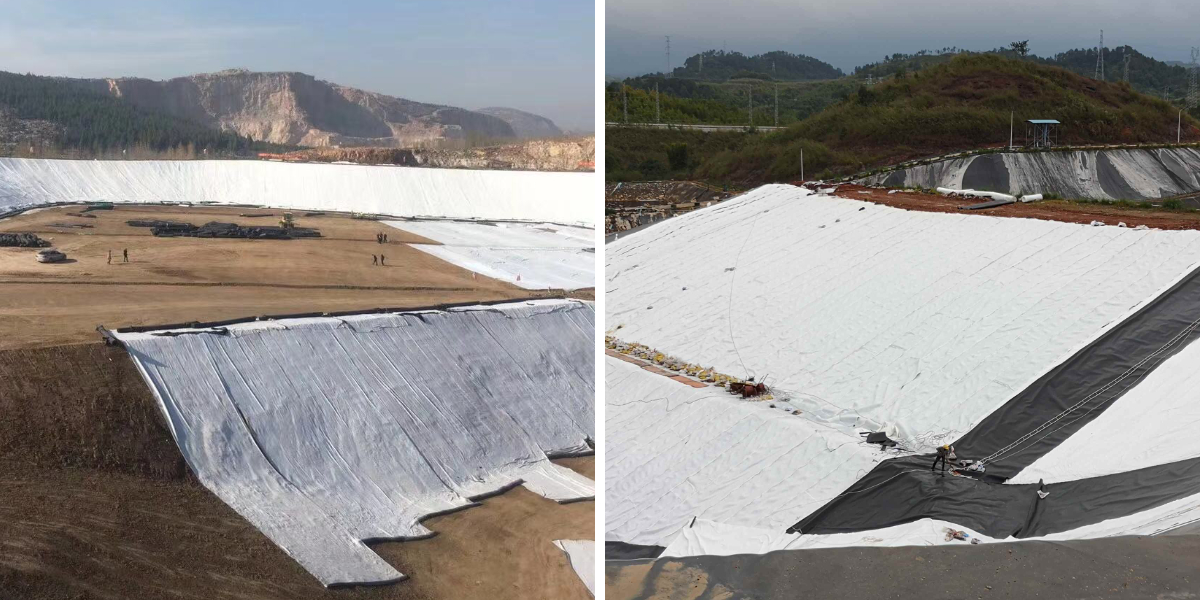

1. Water conservancy engineering (core functions: filtration, drainage, anti-seepage assistance)

River/channel slope protection: Lay geotextile between the slope protection soil and the gravel layer to prevent soil particles from flowing away (filtering) with water flow, and at the same time, guide water seepage (drainage) in the soil to avoid slope collapse;

Auxiliary anti-seepage layer for reservoirs/dams: Geotextile is laid between the anti-seepage membrane (such as HDPE membrane) and the soil to protect the anti-seepage membrane from being punctured by sharp stones, while also providing drainage function (to avoid water accumulation under the membrane damaging the anti-seepage layer);

Sewage treatment plant sedimentation tank: Geotextile is laid between the soil at the bottom of the tank and the filter material to filter suspended particles in the sewage and prevent filter material blockage.

2. Transportation engineering (core functions: isolation, reinforcement, protection)

Highway/railway subgrade: Lay geotextile between the subgrade fill and the base layer (gravel layer) to isolate soil layers of different materials (to avoid uneven settlement of the subgrade caused by mixing of fill and gravel), while reinforcing the subgrade (to improve the bearing capacity of the subgrade and reduce rutting deformation);

Soft soil foundation treatment: laying geotextile on soft soil foundation (such as silt layer), dispersing upper load (such as roadbed weight) through "reinforcement effect", accelerating soft soil drainage consolidation, and avoiding roadbed settlement and cracking;

Tunnel/Culvert Engineering: Lay geotextile ("waterproof board+geotextile" combination) between the tunnel lining and the surrounding rock to divert water seepage (drainage) from the surrounding rock and protect the waterproof board from being damaged by sharp parts of the rock (protection).

3. Construction engineering (core functions: drainage, isolation)

Building basement: Lay a combination of geotextile and drainage board between the basement floor and soil to divert groundwater in the soil and prevent basement seepage;

Excavation dewatering: Wrap geotextile around the filter pipe on the side wall of the excavation to filter soil particles around the excavation and prevent blockage of the filter pipe (ensuring dewatering effect).

4. Environmental engineering (core functions: filtration, protection)

Landfill site: Lay geotextile at the bottom of the landfill site (above the anti-seepage layer) to filter impurities in the leachate and protect the anti-seepage layer from being punctured by sharp objects from garbage; At the same time, cover the top of the landfill with geotextile to prevent rainwater from washing away the landfill soil (protection), and divert rainwater (drainage);

Tailings pond/sludge treatment: laying geotextile in the tailings storage area, filtering sediment in the tailings water, and recovering water resources; Lay geotextile in the sludge drying plant to isolate sludge from underground soil and avoid polluting groundwater.

5. Agriculture and ecological engineering (core functions: protection, drainage)

Agricultural water conservancy: Lay geotextile at the bottom of irrigation channels to prevent channel leakage (reduce water resource waste) and protect channels from erosion caused by water flow;

Slope ecological restoration: Laying geotextile on exposed slopes (such as mine restoration and road slopes) to fix the surface soil (prevent soil erosion) and provide support for vegetation growth (geotextile can absorb water and promote seed germination).

Geotextile, as a multifunctional helper in geotechnical engineering, has been upgraded from a traditional "auxiliary material" to a "core material" due to its controllable permeability, excellent mechanical properties, high cost-effectiveness, and convenient construction. With the development of engineering technology, geotextiles are still evolving towards "functional composites" and will play a role in more complex engineering scenarios in the future.