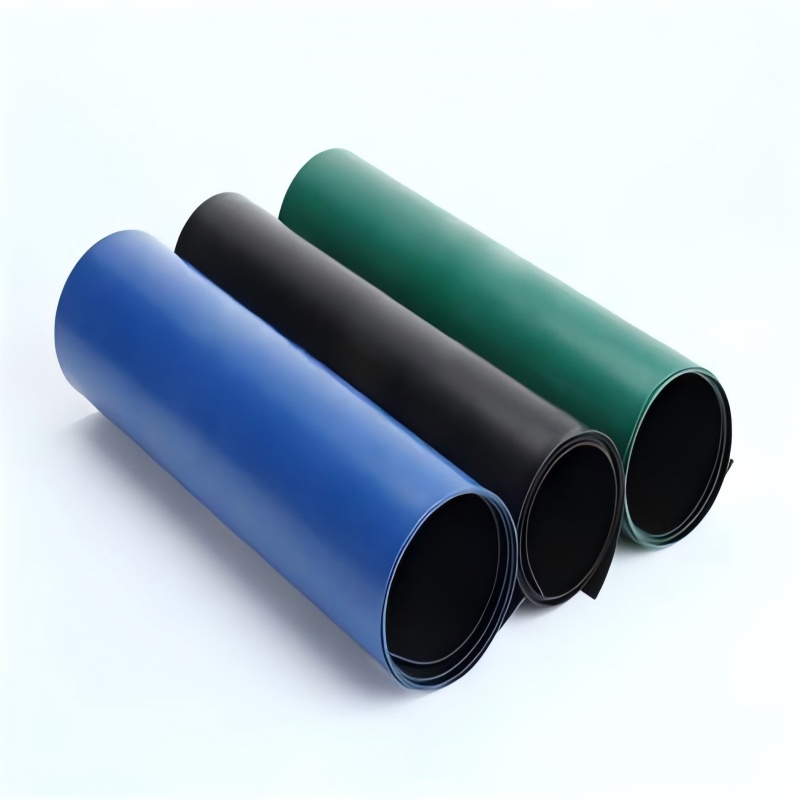

Geomembrane Pond Liner

1. Environmental protection and safety:

Prevent pollutant leakage, protect soil and groundwater.

2. Economically efficient:

Compared to traditional concrete anti-seepage, it has lower costs and faster construction.

3. Strong durability:

The service life can reach 20-50 years (depending on the material and environment).

4. Multifunctionality:

Different materials and thicknesses can be selected according to engineering requirements.

Product Introduction:

Geomembrane Pond Liner is an impermeable film material made from high molecular weight polymers such as polyethylene, polyvinyl chloride, ethylene vinyl acetate copolymer, etc. It is mainly used in engineering scenarios such as isolation, anti-seepage, reinforcement, and protection. It can be used alone or combined with non-woven fabrics to form composite geomembranes, further enhancing its overall performance.

characteristic

1. Excellent anti-seepage performance: The molecular structure is dense and can effectively prevent the infiltration of water, liquids, or gases. The permeability coefficient can usually reach below 10 ⁻¹⁰ cm/s, meeting the anti-seepage requirements of the vast majority of engineering projects.

2. Stable physical and mechanical properties: It has high tensile strength, tear strength, and puncture resistance, and can withstand certain tensile and external impact forces, adapting to deformation and loads in engineering.

3. Good chemical stability: It has strong corrosion resistance to chemicals such as acids, alkalis, and salts, and is not prone to chemical changes under different soil environments and water quality conditions, with a long service life.

4. Strong weather resistance: Geomembranes that have undergone special treatment (such as adding antioxidants, UV absorbers, etc.) can resist the influence of natural environmental factors such as UV radiation and changes in high and low temperatures, and are not easily aged when used outdoors for a long time.

5. Convenient construction: The material is lightweight and weighs much less than traditional anti-seepage materials such as concrete and clay. It is easy to transport and lay, and can be connected by welding, adhesive, and other methods, resulting in high construction efficiency.

Product Parameters:

Metric | ASTM | unit | Test value | Minimum test frequency | ||||||

test method | 0.75 mm | 1.00 mm | 1.25 mm | 1.50 mm | 2.00 mm | 2.50mm | 3.00 mm | |||

Minimum average thickness | D5199 | mm | 0.75 | 1 | 1.25 | 1.5 | 2 | 2.5 | 3 | Per volume |

Minimum value (any one of 10) | -10% | -10% | -10% | -10% | -10% | -10% | -10% | |||

minimum density | D 1505/D 792 | g/cm3 | 0.94 | 0.94 | 0.94 | 0.94 | 0.94 | 0.94 | 0.94 | 90,000 kg |

Minimum average tensile performance (1) | D638 Type IV | |||||||||

Breakage strength, | N/mm | 20 | 27 | 33 | 40 | 53 | 67 | 80 | 9,000 kg | |

yield strength | N/mm | 11 | 15 | 18 | 22 | 29 | 37 | 44 | ||

Strain extension, | % | 700 | 700 | 700 | 700 | 700 | 700 | 700 | ||

yield extension | % | 12 | 12 | 12 | 12 | 12 | 12 | 12 | ||

Minimum strength of right-angle tear | D 1004 | N | 93 | 125 | 156 | 187 | 249 | 311 | 374 | 20,000 kg |

Minimum puncture strength | D4833 | N | 240 | 320 | 400 | 480 | 640 | 800 | 960 | 20,000 kg |

Constant tensile load stress cracking (2) | D5397 | hour | 300 | 300 | 300 | 300 | 300 | 300 | 300 | Based on GRI GM-10 |

Carbon black content | D 1603(3) | % | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 9,000 kg |

Carbon black dispersion | D5596 | Note (4) | Note (4) | Note (4) | Note (4) | Note (4) | Note (4) | Note (4) | 20,000 kg | |

Oxygen induction time (OIT) (5) | 90,000 kg | |||||||||

(a) Standard OIT | D3895 | minute | 100 | 100 | 100 | 100 | 100 | 100 | 100 | |

(b) high-handed OIT | D5885 | minute | 400 | 400 | 400 | 400 | 400 | 400 | 400 | |

85℃ Oven aging (minimum average) (5)(6) | Per formula | |||||||||

(A) Standard OIT is retained after 90 days | D 5721 | % | 55 | 55 | 55 | 55 | 55 | 55 | 55 | |

(B) High voltage OIT is retained for 90 days | D 3895 D5885 | % | 80 | 80 | 80 | 80 | 80 | 80 | 80 | |

Ultraviolet resistance (7) | Per formula | |||||||||

(a) standard OIT | D3895 | Note (8) 50 | ||||||||

(b) Retention of high pressure OIT after 1600 hours (9) | D5885 | % | ||||||||

Product Applications:

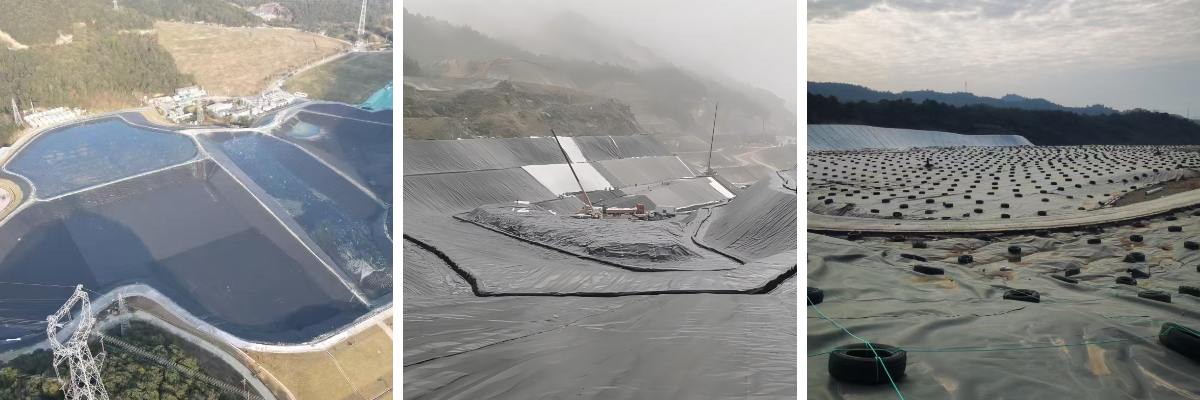

1. Environmental engineering:

Landfill site: As an anti-seepage liner, it isolates leachate from soil to prevent pollution from spreading.

Wastewater treatment plant: used for anti-seepage of the pool body to avoid the impact of sewage leakage on the surrounding environment.

2. Water conservancy engineering:

Reservoirs and dams: laid at the bottom and slopes to reduce leakage losses and improve water resource utilization. For example, the Three Gorges Reservoir adopts HDPE geomembrane for anti-seepage treatment.

Irrigation channels: reduce leakage during water delivery, improve irrigation efficiency, and have significant water-saving effects.

3. Municipal engineering:

Subway tunnel: As an anti-seepage lining, it prevents groundwater infiltration and ensures construction safety.

Basement waterproofing: prevent groundwater infiltration and ensure the building structure is dry and stable.

4. Agriculture and Fisheries:

Fish ponds and lotus root ponds: impermeable membranes can isolate bacteria in the soil, reduce water waste, and increase aquaculture density. For example, 0.5mm thick HDPE film is widely used in fish ponds.

Salt field brine tank: covered with geomembrane to prevent salt leakage and improve crystallization efficiency.

5. Mining and Transportation:

Washing and heap leaching tanks: prevent leakage of mineral wastewater, protect soil and water bodies.

Highway and railway: used for foundation reinforcement and culvert anti-seepage, enhancing roadbed stability, and extending service life.

Geomembranes, with their excellent performance and wide applicability, have become an indispensable and important material in modern civil engineering, providing strong guarantees for the safety, stability, and environmental protection of various projects.