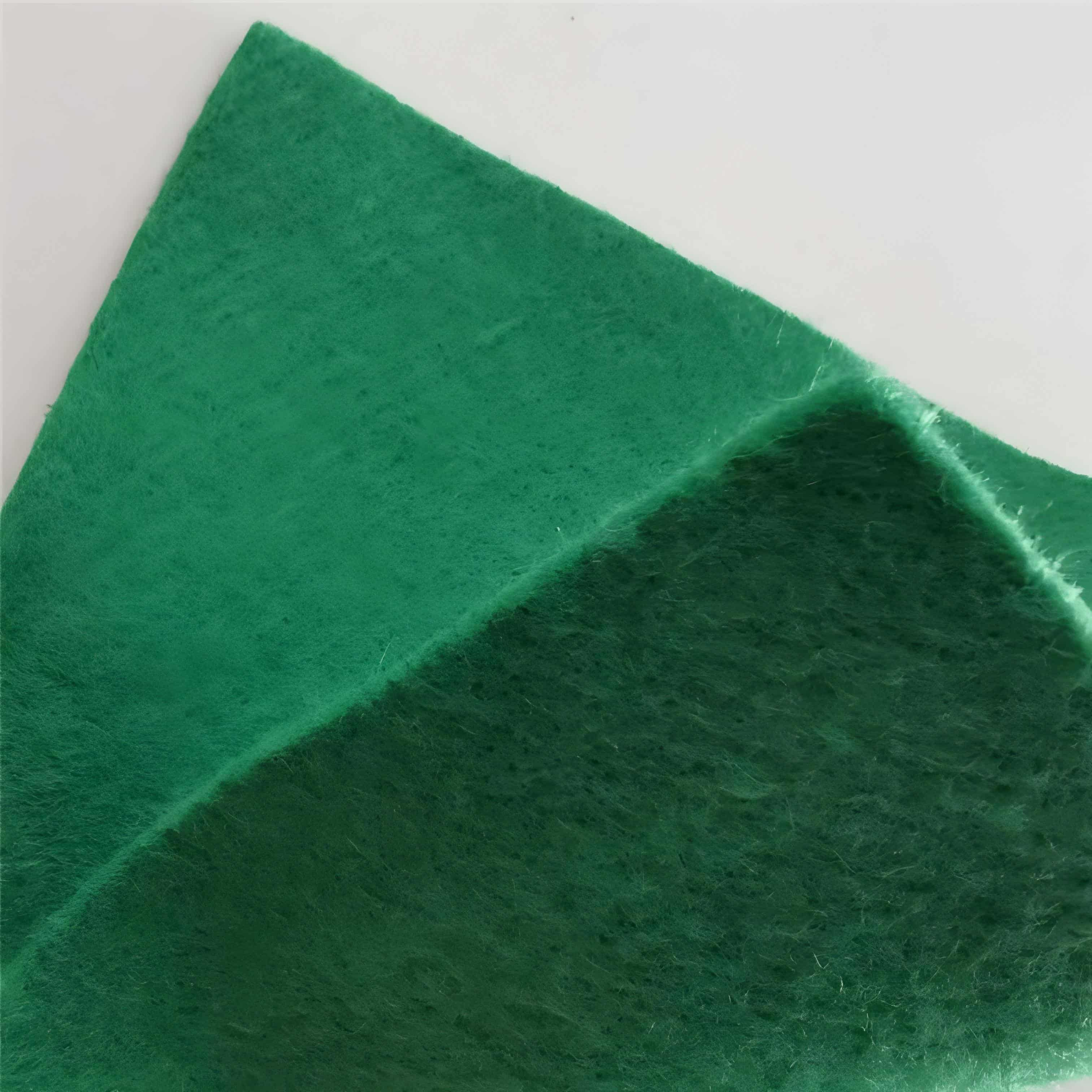

4 oz Non Woven Geotextile

1.Strong load-bearing and tensile resistance: The fibers are tightly interwoven and can withstand soil pressure and construction loads, effectively resisting tensile deformation.

2.Dual effect of anti-seepage and water filtration: Blocking sediment loss while allowing water infiltration, balancing engineering anti-seepage and drainage needs.

3.Suitable for various working conditions: Lightweight design for easy laying, suitable for various geotechnical scenarios such as roadbeds, slopes, and water conservancy.

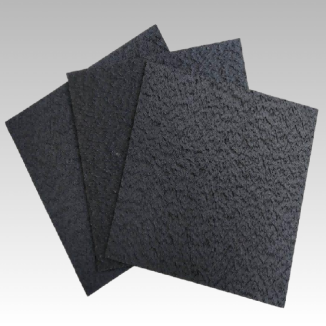

4.Strong weather resistance and durability: Resistant to ultraviolet rays, acid and alkali corrosion, maintaining long-term stability in complex outdoor environments.

Product Introduction

1、 Basic attributes

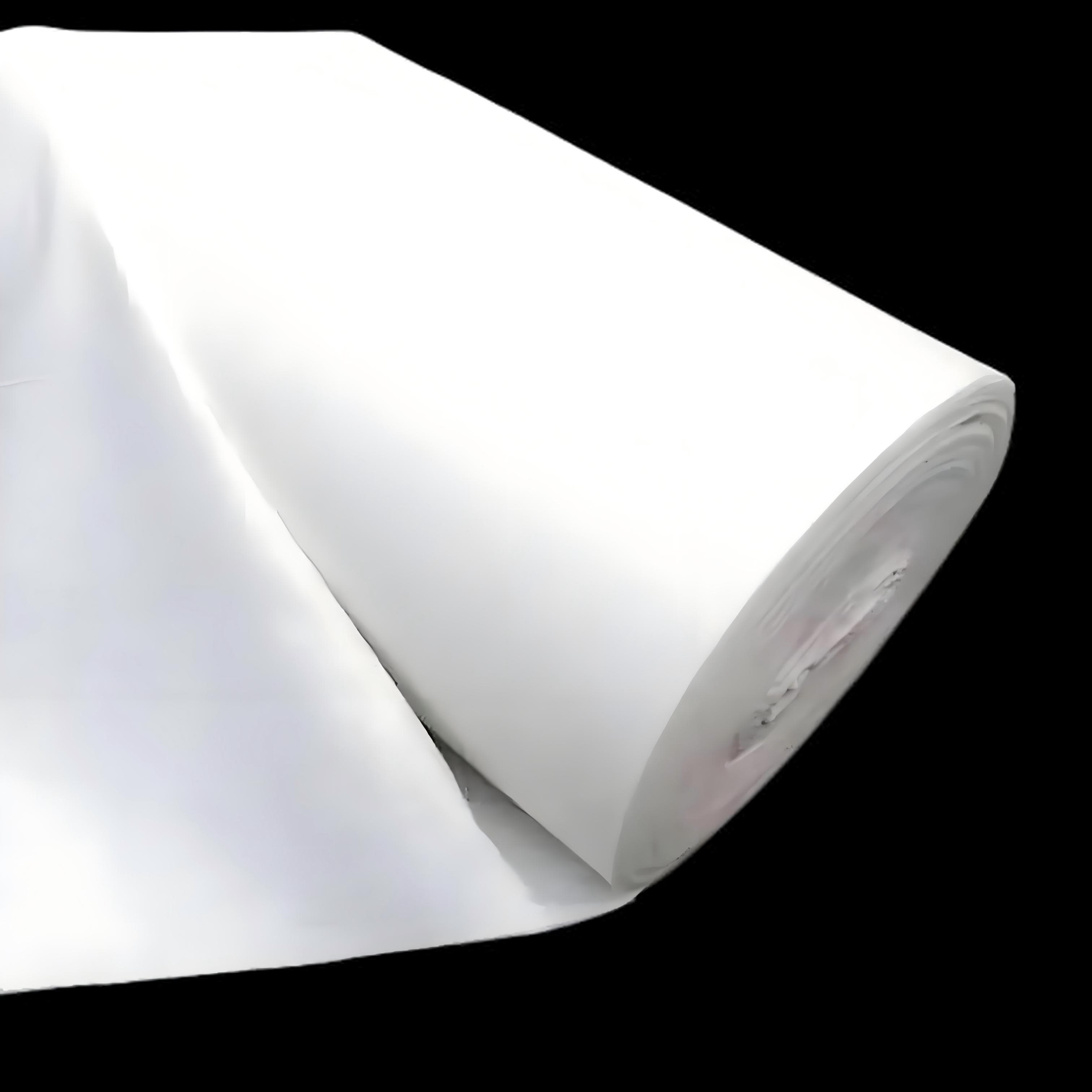

4 oz Non Woven Geotextile is made from polymer fibers through non-woven technology, with a unit weight of 4 ounces per square yard (approximately 136 grams per square meter). Its material is lightweight and tightly structured, with stable physical and mechanical properties, making it a flexible geosynthetic material that is easy to transport, cut, and lay on site.

2、 Core functions

As a fundamental material in engineering, its core functions are reflected in three aspects: firstly, structural reinforcement, which disperses soil pressure and construction loads through the load-bearing characteristics of interwoven fibers, reducing settlement deformation of roadbeds and slopes; The second is soil and water conservation, which achieves a dual function of "anti-seepage+water filtration" through a special fiber structure, which not only blocks sediment loss but also ensures the normal infiltration and discharge of water; The third is environmental adaptation, providing a basic protective layer for various geotechnical scenarios, adapting to core requirements such as roadbed reinforcement, slope protection, and water conservancy engineering anti-seepage.

3、 Main features

Strong and durable: The tightly interwoven fibers endow it with high tensile resistance, as well as UV resistance and acid alkali corrosion resistance, which can maintain stable performance in complex outdoor environments for a long time.

Efficient and practical: Lightweight design reduces the difficulty of laying, high construction efficiency, and a single material can serve multiple functions such as load-bearing, anti-seepage, and water filtration, reducing the cost of material combination in engineering.

Wide scene adaptation: It can be applied to various geotechnical conditions such as roads, water conservancy, municipal engineering, mining, etc. without complex modification, and is suitable for different geological conditions and construction environments.

Product Parameters

project | metric | ||||||||||

Nominal strength/(kN/m) | |||||||||||

6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |||

1 | Longitudinal and transverse tensile strength / (kN/m) ≥ | 6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |

2 | Maximum elongation at maximum load in longitudinal and transverse directions/% | 30~80 | |||||||||

3 | CBR top penetration strength /kN ≥ | 0.9 | 1.6 | 1.9 | 2.9 | 3.9 | 5.3 | 6.4 | 7.9 | 8.5 | |

4 | Longitudinal and transverse tearing strength /kN | 0.15 | 0.22 | 0.29 | 0.43 | 0.57 | 0.71 | 0.83 | 1.1 | 1.25 | |

5 | Equivalent aperture O.90(O95)/mm | 0.05~0.30 | |||||||||

6 | Vertical permeability coefficient/(cm/s) | K× (10-¹~10-), where K=1.0~9.9 | |||||||||

7 | Width deviation rate /% ≥ | -0.5 | |||||||||

8 | Unit area mass deviation rate /% ≥ | -5 | |||||||||

9 | Thickness deviation rate /% ≥ | -10 | |||||||||

10 | Thickness coefficient of variation (CV)/% ≤ | 10 | |||||||||

11 | Dynamic perforation | Puncture hole diameter/mm ≤ | 37 | 33 | 27 | 20 | 17 | 14 | 11 | 9 | 7 |

12 | Longitudinal and transverse fracture strength (grab method)/kN ≥ | 0.3 | 0.5 | 0.7 | 1.1 | 1.4 | 1.9 | 2.4 | 3 | 3.5 | |

13 | Ultraviolet resistance (Xenon arc lamp method) | Longitudinal and transverse strength retention rate% ≥ | 70 | ||||||||

14 | Ultraviolet resistance (fluorescence UV lamp method) | Longitudinal and transverse strength retention rate% ≥ | 80 | ||||||||

Product Application

1. Road engineering: Building a strong protective barrier at the grassroots level

In the grassroots construction of rural and municipal roads, it is laid parallel to the road surface between the subgrade soil and the base material. On the one hand, by utilizing the tensile properties of interwoven fibers, the load generated by vehicle travel can be evenly dispersed, reducing problems such as settlement and cracks caused by uneven stress on the road surface; On the other hand, its permeability can quickly drain accumulated water from the base layer, avoiding water retention and softening of the roadbed, significantly improving the stability of the road base layer, and extending the service life of the road by 3-5 years.

2. Slope protection: safeguarding the ecological safety of water and soil

For areas prone to soil erosion such as mountain slopes and embankment slopes, horizontal overlap and vertical anchoring are used for laying. The fiber structure can tightly adhere to the soil surface, fix the loose soil on the surface, and effectively block the sediment loss caused by rainwater erosion; At the same time, the porous nature of the fabric allows for the infiltration and discharge of moisture inside the slope, reducing soil moisture content and avoiding landslides and collapses caused by increased slope weight due to accumulated water. In projects such as mine greening and ecological restoration of highway slopes, it can reduce the cost of soil erosion control in the later stage.

3. Water conservancy engineering: balancing anti-seepage and drainage requirements

In the construction of water conservancy facilities such as small reservoirs and agricultural irrigation channels, they are laid at the foot of the inner slope of the dam or at the bottom of the channel. Its tight fiber structure can block water leakage to the outside of dams or channels, reducing water resource loss; At the same time, it can filter sediment and impurities in water, prevent them from blocking drainage channels, and ensure the normal water supply function of water conservancy facilities. In channel renovation projects, it can reduce the risk of soil salinization caused by leakage.

4. Municipal infrastructure: Strengthen engineering isolation and protection

When laying underground pipelines (such as water pipes and cables), wrapping them around the outside of the pipeline or laying them in the soil layer around the pipeline can isolate different types of soil layers, prevent impurities from entering the pipeline and affecting structural stability, and block the wear and tear of gravel and sharp objects on the pipeline, reducing the probability of pipeline maintenance. In landfill engineering, the protective layer of the anti-seepage membrane is laid on both sides of the membrane body, which can buffer the impact force during landfill, prevent the anti-seepage membrane from being punctured, and enhance the anti-seepage effect of the landfill.

4 oz Non Woven Geotextile, with its multiple functions of "load-bearing anti-seepage filtering isolation", has become an efficient and practical basic protective material in engineering fields such as roads, slopes, water conservancy, and municipal engineering. Its lightweight design reduces construction difficulty, and its weather resistant and durable characteristics ensure long-term stability. It effectively solves core problems such as settlement, soil erosion, and leakage in engineering, and provides reliable support for the safe construction and long-term operation of various projects by reducing material matching and maintenance costs.