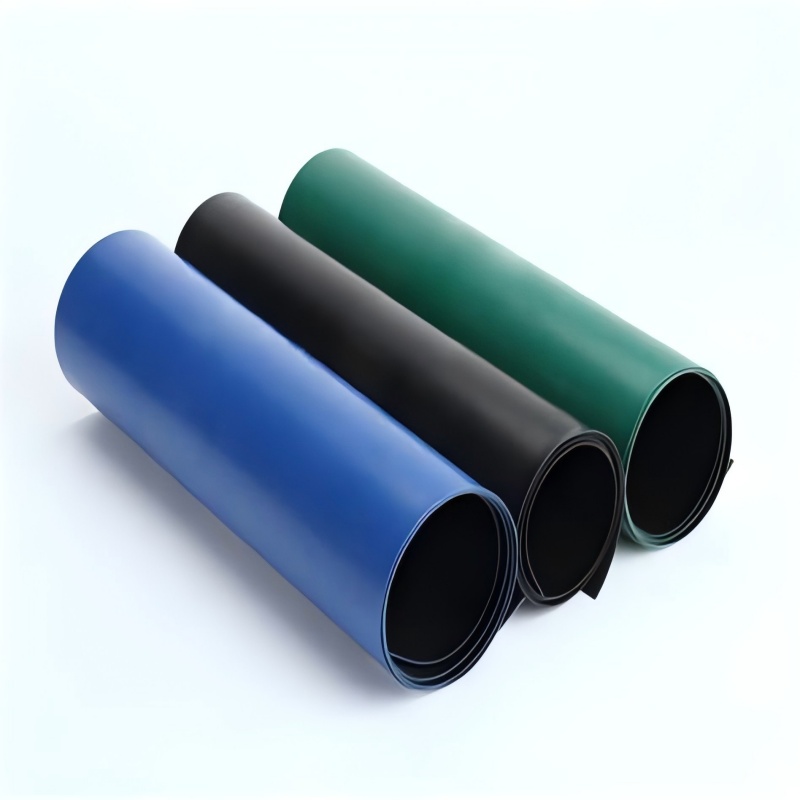

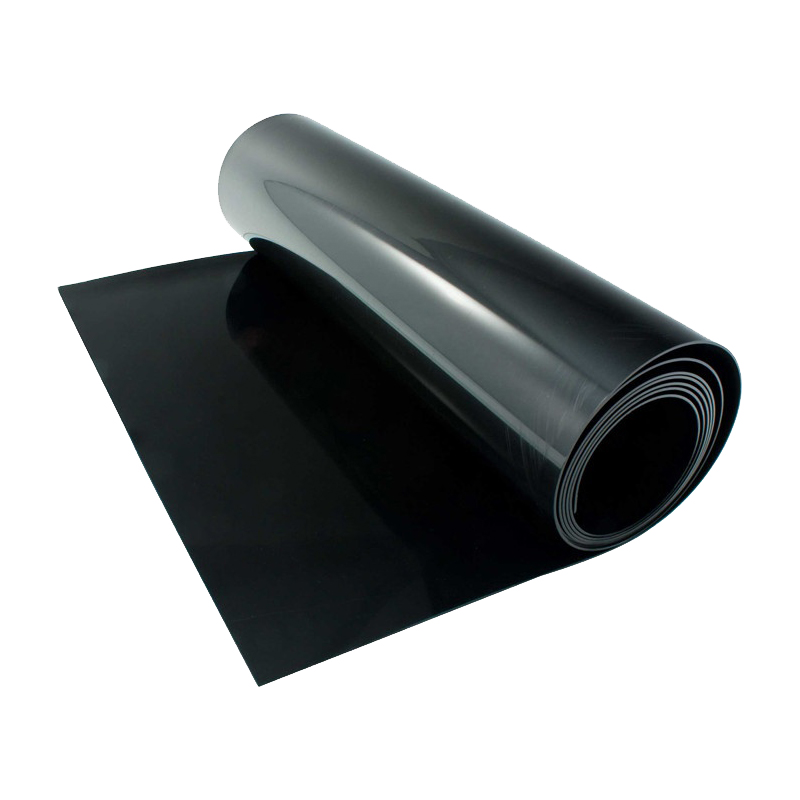

HDPE Geomembrane Pond Liner

1. Significant anti-seepage effect

Compared to traditional anti-seepage materials, geomembranes have higher anti-seepage efficiency and can significantly reduce leakage losses, especially suitable for projects with strict anti-seepage requirements.

2. High cost-effectiveness

The unit price of materials is relatively low, and the construction period is short, the labor cost is low, and the overall cost is lower than that of rigid materials such as concrete. Long service life and low maintenance costs in the later stage.

3. Strong adaptability

Has good flexibility and extensibility, can adapt to environmental factors such as foundation settlement and temperature changes, is not easy to crack, and reduces engineering hazards.

Product Introduction:

HDPE Geomembrane Pond Liner is a flexible waterproof and barrier material made from high molecular weight polymers such as high-density polyethylene (HDPE), polyvinyl chloride (PVC), and low-density polyethylene (LDPE) through processes such as high-temperature melting, extrusion, and rolling. Its core function is to achieve anti-seepage, waterproofing, isolation, and enhance the stability of engineering structures through physical barriers, and it is widely used in engineering scenarios with high environmental adaptability requirements.

characteristic

1. Super strong anti-seepage performance

The anti-seepage coefficient can reach 1 × 10 ⁻¹⁷ cm/s, effectively blocking the infiltration of water, liquids, and gases.

2. Weather resistance and aging resistance

Under the influence of external factors such as ultraviolet radiation and oxygen, the physical properties of HDPE geomembrane change very little, and the melting point gradually increases with aging. It has excellent thermal stability and can be used for a long time without degradation.

3. Chemical corrosion resistance

It can resist strong acids, alkalis, oils, and salt spray erosion, and is suitable for corrosive environments such as chemical storage tanks and mining tailings ponds.

4. High tensile strength and adaptability

HDPE geomembrane can withstand the stress caused by uneven geological settlement and avoid cracking. In steep slope protection engineering, its tensile strength can ensure the stability of the slope structure.

5. Wide temperature range working ability

The operating temperature range is -70 ℃ to 110 ℃, suitable for extremely cold or high temperature environments.

6. Convenience and economy of construction

The material is soft and easy to bend, and can be quickly connected by hot melt welding. The welding strength is higher than that of the base material.

Product Parameters:

Metric | ASTM | unit | Test value | Minimum test frequency | ||||||

test method | 0.75 mm | 1.00 mm | 1.25 mm | 1.50 mm | 2.00 mm | 2.50mm | 3.00 mm | |||

Minimum average thickness | D5199 | mm | 0.75 | 1 | 1.25 | 1.5 | 2 | 2.5 | 3 | Per volume |

Minimum value (any one of 10) | -10% | -10% | -10% | -10% | -10% | -10% | -10% | |||

minimum density | D 1505/D 792 | g/cm3 | 0.94 | 0.94 | 0.94 | 0.94 | 0.94 | 0.94 | 0.94 | 90,000 kg |

Minimum average tensile performance (1) | D638 Type IV | |||||||||

Breakage strength, | N/mm | 20 | 27 | 33 | 40 | 53 | 67 | 80 | 9,000 kg | |

yield strength | N/mm | 11 | 15 | 18 | 22 | 29 | 37 | 44 | ||

Strain extension, | % | 700 | 700 | 700 | 700 | 700 | 700 | 700 | ||

yield extension | % | 12 | 12 | 12 | 12 | 12 | 12 | 12 | ||

Minimum strength of right-angle tear | D 1004 | N | 93 | 125 | 156 | 187 | 249 | 311 | 374 | 20,000 kg |

Minimum puncture strength | D4833 | N | 240 | 320 | 400 | 480 | 640 | 800 | 960 | 20,000 kg |

Constant tensile load stress cracking (2) | D5397 | hour | 300 | 300 | 300 | 300 | 300 | 300 | 300 | Based on GRI GM-10 |

Carbon black content | D 1603(3) | % | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 9,000 kg |

Carbon black dispersion | D5596 | Note (4) | Note (4) | Note (4) | Note (4) | Note (4) | Note (4) | Note (4) | 20,000 kg | |

Oxygen induction time (OIT) (5) | 90,000 kg | |||||||||

(a) Standard OIT | D3895 | minute | 100 | 100 | 100 | 100 | 100 | 100 | 100 | |

(b) high-handed OIT | D5885 | minute | 400 | 400 | 400 | 400 | 400 | 400 | 400 | |

85℃ Oven aging (minimum average) (5)(6) | Per formula | |||||||||

(A) Standard OIT is retained after 90 days | D 5721 | % | 55 | 55 | 55 | 55 | 55 | 55 | 55 | |

(B) High voltage OIT is retained for 90 days | D 3895 D5885 | % | 80 | 80 | 80 | 80 | 80 | 80 | 80 | |

Ultraviolet resistance (7) | Per formula | |||||||||

(a) standard OIT | D3895 | Note (8) 50 | ||||||||

(b) Retention of high pressure OIT after 1600 hours (9) | D5885 | % | ||||||||

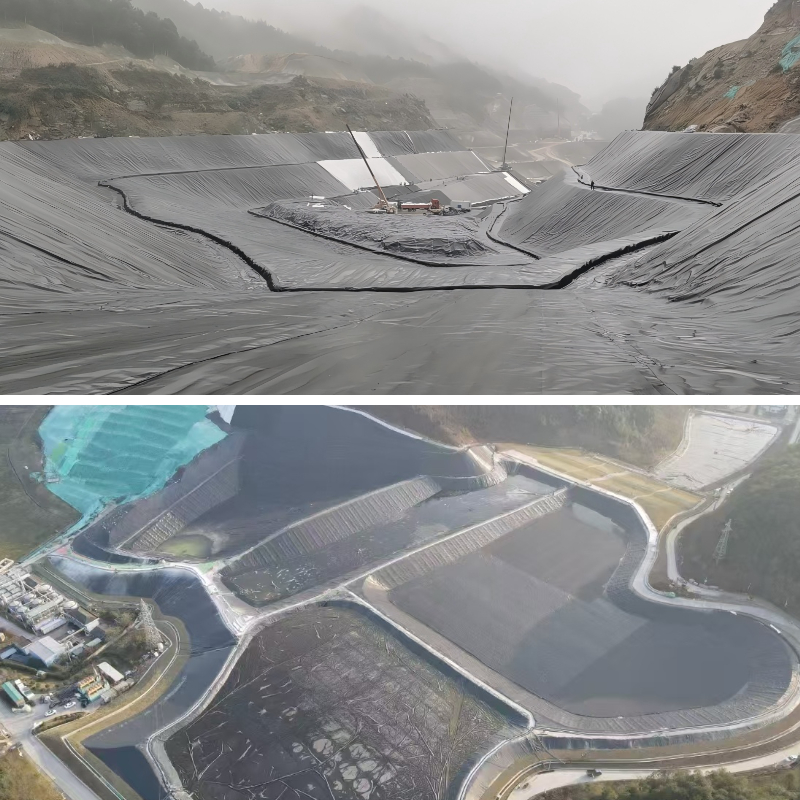

Product Applications:

1. Water conservancy engineering

Reservoir/embankment: As an anti-seepage lining, it prevents water leakage and soil erosion. For example, in the Three Gorges Project, HDPE geomembrane was used to construct impermeable walls, reducing leakage by 90%.

Channel/Canal: Replace traditional concrete lining, reduce cost and improve anti-seepage effect.

2. Environmental engineering

Landfill site: Geomembranes are laid on the bottom and side walls to prevent leachate from contaminating groundwater. The Beijing Asuwei landfill adopts a double-layer geomembrane system, reducing the risk of leachate leakage to 0.01% per year.

Sewage treatment plant: anti-seepage isolation of facilities such as regulating tanks and oxidation tanks to avoid soil pollution caused by sewage leakage.

3. Mining Engineering

Tailings pond: prevent the infiltration and pollution of groundwater by acidic slag. The tailings pond of a gold mine in Australia adopts a geotextile anti-seepage layer, and the pH value of the surrounding groundwater is stable between 6.5-7.5.

Heap leaching tank: used for preventing seepage of solutions during the extraction process of precious metals, improving resource utilization efficiency.

4. Agricultural Engineering

Reservoir/irrigation system: prevents water evaporation and leakage, and improves water resource utilization efficiency. The use of geomembrane reservoirs in cotton fields in Xinjiang has increased irrigation efficiency by 40%.

Salt field: The plastic film covering the salt pond can control the evaporation rate and improve salt production efficiency.

5. Transportation Engineering

Highway/railway subgrade: prevent groundwater from softening the subgrade and extend the service life of the pavement. Some sections of the Qinghai Tibet Railway use geomembranes to isolate frozen soil layers, effectively preventing roadbed settlement.

Tunnel anti-seepage: Construct waterproof barriers in subways and underwater tunnels to ensure structural safety.

6. Landscape engineering

Artificial lake/golf course: prevent lake water leakage and soil erosion, maintain beautiful landscape. A golf course in Shenzhen adopts a geotextile anti-seepage layer, reducing annual water replenishment by 60%.

Roof garden: As a waterproof layer, it prevents plant roots from penetrating and causing roof leakage.

From water resource protection in hydraulic engineering to pollution prevention and control in environmental engineering, from safe production in mining engineering to water-saving and efficiency improvement in agricultural engineering, geomembranes have become an indispensable key material in modern engineering due to their excellent performance and wide application scenarios. With the advancement of materials science, new types of geomembranes continue to emerge, and their performance will be further improved, providing more reliable solutions for global infrastructure construction.