Non Woven Polypropylene Geotextile

1.Material characteristics: Chemically stable, resistant to acid and alkali, salt spray and aging, resistant to microorganisms and pests, suitable for humid and dark environments; Lightweight (100-600g/㎡), flexible, easy to transport and lay, suitable for irregular terrain.

2.Functional performance: Three dimensional structure with strong tensile strength, tear and puncture resistance, stable dry and wet performance; Uniform pores with good permeability (10 ⁻¹ -10 ⁻³ cm/s), capable of draining and preventing loss; After adding UV resistance, it has excellent weather resistance, stable performance from -40 ℃ to 60 ℃, and a lifespan of over 20 years.

3.Engineering adaptability: The width can be customized (2-6 meters), and manual laying is fast and time-saving; Low cost, high efficiency, better cost-effectiveness than similar products, reducing long-term maintenance costs; Non toxic, environmentally friendly, and recyclable, in line with the concept of green engineering.

Product Introduction

1.Basic attributes

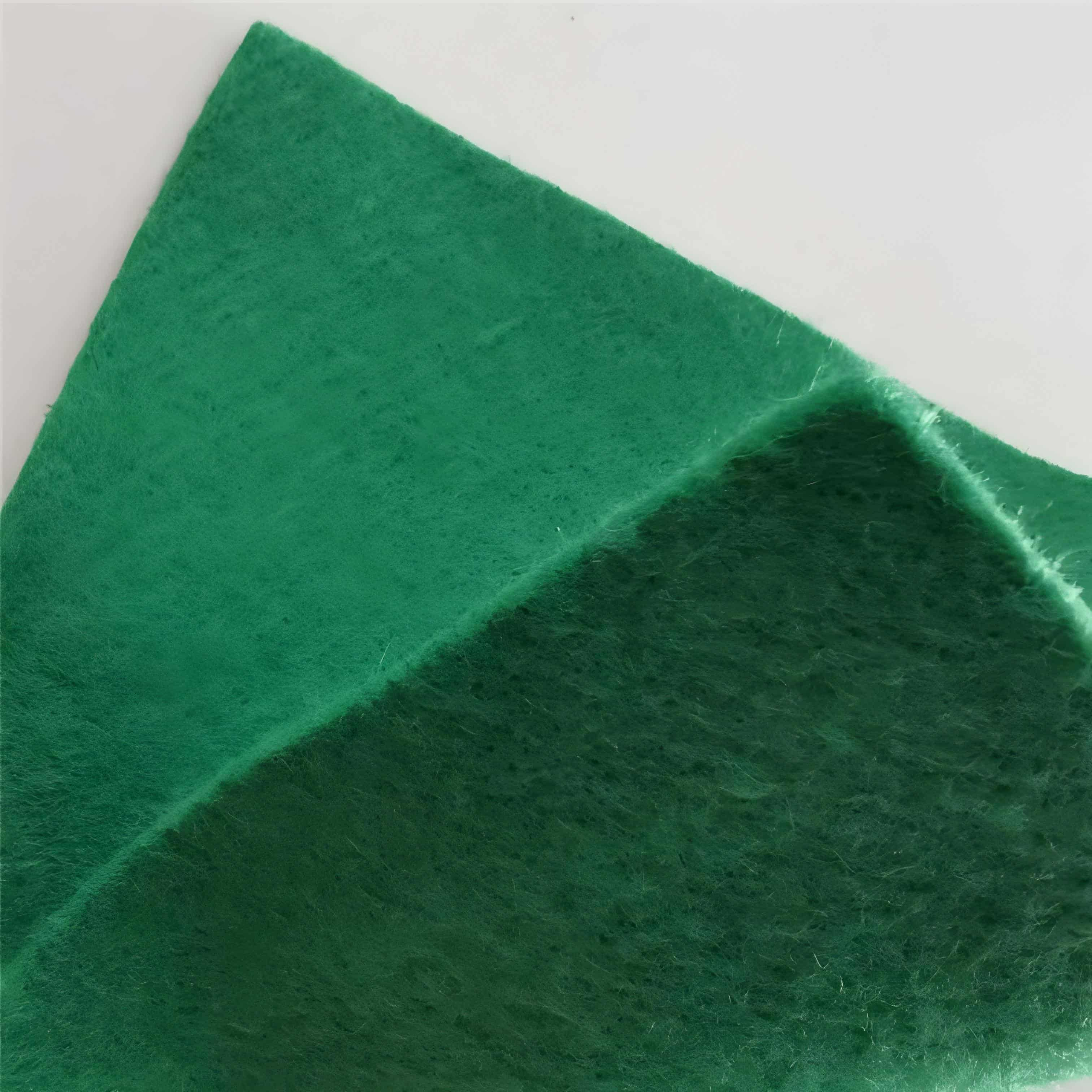

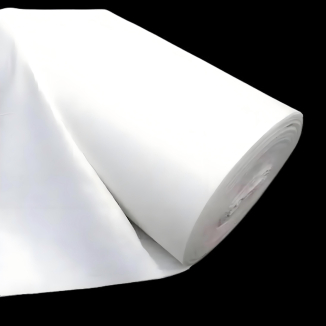

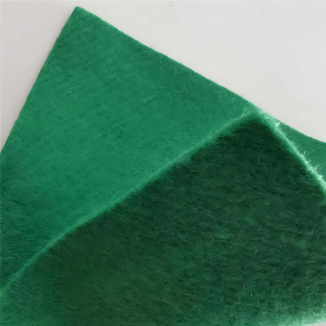

Non Woven Polypropylene Geotextile is a flexible sheet material made from polypropylene polymer as raw material, processed through non-woven processes such as needle punching, thermal bonding, or chemical bonding. Its core attributes include:

Material foundation: Using polypropylene fibers as the core material, the fibers are arranged in a disordered or oriented manner and then combined through physical or chemical reactions to form a porous fabric. The unit area mass is usually 100-600g/㎡, and the width can be customized to 2-6 meters.

Chemical essence: Polypropylene material determines its natural resistance to chemical corrosion, strong resistance to acid, alkali, salt spray and other erosion, and no biological toxicity. It has good compatibility with environmental media such as soil and water.

Physical characteristics: The texture is light and soft, foldable, and can be cut to adapt to different terrain contours. It also has a certain degree of elasticity and toughness, making it easy to operate during construction.

2.Core functions

As a geotechnical material used in engineering, its core function revolves around the protection and performance improvement of engineering structures:

Enhancement and reinforcement: With the high-strength characteristics of three-dimensional structures, the tensile strength and deformation resistance of soil, roadbed and other structures are enhanced, external loads are dispersed, and the risk of settlement or collapse is reduced.

Drainage and filtration: By utilizing the interconnected pores between fibers, the accumulated water inside the soil or engineering structure can be quickly drained, while retaining sand particles, achieving "drainage without soil loss" and maintaining structural stability.

Isolation and protection: Separate materials with different physical properties (such as soil and sand, base and cushion) to prevent mixed loss; Simultaneously protect the main body of the project (such as pipelines, impermeable membranes) from sharp object punctures or external wear and tear.

3.Main features

Compared to other geotechnical materials, its outstanding features are reflected in practicality and adaptability:

Strong performance stability: Stable mechanical properties under dry and wet conditions, excellent tear and puncture resistance; After adding anti UV additives, the weather resistance is excellent in environments ranging from -40 ℃ to 60 ℃, with a service life of over 20 years.

High construction efficiency: lightweight and soft, can be manually laid without the need for large machinery, easy to assemble, can adapt to narrow sites or emergency engineering needs, effectively shortening the construction period.

Outstanding cost-effectiveness: Polypropylene raw material cost is low, non-woven process production efficiency is high, and comprehensive cost is lower than similar materials; And its long-term performance is stable, which can reduce maintenance costs and lower the overall lifecycle cost.

Good environmental adaptability: The materials are non-toxic and harmless, with no secondary pollution to the environment. Some products can be recycled and reused, meeting the requirements of green engineering and sustainable development.

Product Parameters

project | metric | ||||||||||

Nominal strength/(kN/m) | |||||||||||

6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |||

1 | Longitudinal and transverse tensile strength / (kN/m) ≥ | 6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |

2 | Maximum elongation at maximum load in longitudinal and transverse directions/% | 30~80 | |||||||||

3 | CBR top penetration strength /kN ≥ | 0.9 | 1.6 | 1.9 | 2.9 | 3.9 | 5.3 | 6.4 | 7.9 | 8.5 | |

4 | Longitudinal and transverse tearing strength /kN | 0.15 | 0.22 | 0.29 | 0.43 | 0.57 | 0.71 | 0.83 | 1.1 | 1.25 | |

5 | Equivalent aperture O.90(O95)/mm | 0.05~0.30 | |||||||||

6 | Vertical permeability coefficient/(cm/s) | K× (10-¹~10-), where K=1.0~9.9 | |||||||||

7 | Width deviation rate /% ≥ | -0.5 | |||||||||

8 | Unit area mass deviation rate /% ≥ | -5 | |||||||||

9 | Thickness deviation rate /% ≥ | -10 | |||||||||

10 | Thickness coefficient of variation (CV)/% ≤ | 10 | |||||||||

11 | Dynamic perforation | Puncture hole diameter/mm ≤ | 37 | 33 | 27 | 20 | 17 | 14 | 11 | 9 | 7 |

12 | Longitudinal and transverse fracture strength (grab method)/kN ≥ | 0.3 | 0.5 | 0.7 | 1.1 | 1.4 | 1.9 | 2.4 | 3 | 3.5 | |

13 | Ultraviolet resistance (Xenon arc lamp method) | Longitudinal and transverse strength retention rate% ≥ | 70 | ||||||||

14 | Ultraviolet resistance (fluorescence UV lamp method) | Longitudinal and transverse strength retention rate% ≥ | 80 | ||||||||

Product Application

1.Water conservancy engineering field

Dam anti-seepage and reinforcement: In dam construction, non-woven polypropylene geotextile can be laid on the upstream face of the dam or inside the dam body as a protective layer for the anti-seepage layer, preventing the anti-seepage membrane from being pierced by sharp objects, reducing friction between the dam soil material and the anti-seepage membrane, and extending the service life of the anti-seepage system. In addition, laying it in the fill soil of the dam can enhance the overall integrity and shear strength of the dam, effectively preventing landslides and collapses of the dam.

River regulation: Geotextiles can be used for riverbank protection in dredging and bank protection projects. Laying it on the surface of the riverbank and covering it with soil or stone blocks can reduce the erosion of water flow on the riverbank, protect the stability of the riverbank structure, and allow water infiltration to maintain the ecological balance of the river channel.

Reservoir engineering: In the dam body, bank, and anti-seepage treatment of the reservoir, non-woven polypropylene geotextile can be used as a filter layer and drainage layer. It can prevent the loss of soil particles in the reservoir with water, ensure the stability of the dam body and reservoir bank, and discharge the seepage in the dam body and reservoir bank, reducing the pore water pressure.

2.Transportation engineering field

Highway construction:

Roadbed reinforcement: Laying non-woven polypropylene geotextile in the filling soil of highway subgrade can disperse the load borne by the subgrade, reduce uneven settlement of the subgrade, and improve the stability and bearing capacity of the subgrade.

Isolation between pavement base and sub base: Laying geotextile between pavement base and sub base can prevent the mixing of base and sub base materials, ensuring the structural performance of the base and sub base.

Drainage function: Geotextile has good permeability and can be used as a drainage layer to be laid in the pavement structure, timely draining accumulated water in the pavement structure and reducing water damage to the pavement.

Railway construction: The use of non-woven polypropylene geotextiles in railway subgrades, trackbeds, and other areas can serve as reinforcement, isolation, drainage, and other functions, improving the stability and safety of railway lines and reducing maintenance costs.

Airport engineering: In the construction of airport runways, aprons, and other areas, geotextiles can be used for foundation treatment, base reinforcement, and drainage systems to ensure that the airport site has sufficient strength and stability to meet the requirements for aircraft takeoff and landing.

3.In the field of civil engineering

Building foundation treatment: For weak foundations, reinforcement treatment can be carried out by laying non-woven polypropylene geotextiles and combining them with fill soil to improve the bearing capacity of the foundation and reduce its settlement.

Retaining wall engineering: Laying geotextile behind the retaining wall can serve as a filter layer to prevent soil particles in the backfill behind the wall from flowing away with water, while also draining water seepage behind the wall, reducing water pressure behind the wall, and improving the stability of the retaining wall.

Tunnel engineering: Laying geotextile between the initial support and secondary lining of the tunnel can play a role in waterproofing, drainage, and isolation, protecting the tunnel structure and ensuring its normal use.

4.Environmental engineering field

Landfill site: Non woven polypropylene geotextile is widely used in landfills as a protective layer, drainage layer, and filter layer for anti-seepage systems. It can protect the anti-seepage membrane from being punctured by garbage, while discharging leachate from garbage, preventing pollutants from garbage from penetrating into soil and groundwater, and protecting the environment.

Sewage treatment: Geotextile can be used as a filtering material in sedimentation tanks, filters and other facilities of sewage treatment plants to filter suspended particles in sewage and improve the effectiveness of sewage treatment.

Ecological restoration: In ecological restoration projects of rivers, lakes and other water bodies, laying geotextiles can prevent soil erosion, provide a habitat for aquatic organisms, and promote the restoration of ecosystems.

5.Agriculture and Horticulture

Agricultural water conservancy: In the construction of agricultural irrigation channels, non-woven polypropylene geotextiles can be used for channel seepage prevention and slope protection, reducing channel leakage losses, improving irrigation efficiency, and protecting channel slopes from water erosion.

Horticultural planting: In horticultural planting, geotextiles can be laid on the soil surface to prevent weed growth, retain water and heat, and improve the quality of the plant's growth environment.

6.Other fields

Mining engineering: The use of non-woven polypropylene geotextiles in tailings dams, storage yards, and other areas of mines can serve as reinforcement, anti-seepage, drainage, and other functions to prevent tailings leakage from polluting the environment.

Power engineering: In the construction of tower foundations and substation sites for power lines, geotextiles can be used for foundation treatment and drainage systems to improve the stability and safety of power facilities.

In short, non-woven polypropylene geotextile, as a high-performance geosynthetic material, has become an indispensable key material in modern engineering construction. It has built a comprehensive application network in many fields such as water conservancy, transportation, civil engineering, environmental protection, agriculture, etc., relying on its core advantages of light weight, high strength, acid and alkali corrosion resistance, excellent water permeability, and controllable cost. From anti-seepage reinforcement to safeguard the safety of dams, to load dispersion to ensure the stability of highway and railway roadbeds; From environmental barriers in landfills to water-saving slope protection in agricultural water conservancy, every application scenario demonstrates its important value in improving engineering quality, reducing maintenance costs, and strengthening ecological protection. With the continuous innovation of engineering technology and the continuous improvement of environmental protection requirements, the performance of nonwoven polypropylene geotextile is still being optimized. For example, its aging resistance, weather resistance and mechanical strength are further improved through process improvement, so that it can adapt to more complex geological environment and more stringent engineering conditions. At the same time, its application areas are constantly expanding towards refinement and diversification, and its potential in emerging fields such as sponge city construction, saline alkali land improvement, and green buildings is gradually emerging. It can be foreseen that non-woven polypropylene geotextiles will continue to play an irreplaceable role in future engineering construction and ecological protection, providing solid material support for promoting high-quality infrastructure development and achieving sustainable development goals. Their application prospects will be even broader and more profound.