Non Woven Silt Fence

1. Efficient filtration of sediment: Non woven geotextiles have excellent water permeability and filtration performance, which can effectively intercept small soil particles and produce clearer water.

2. Environmental protection: It is a key tool for controlling soil erosion, preventing eutrophication of water bodies, and protecting surrounding ecosystems, in compliance with environmental regulations.

3. Easy and fast installation: The components are simple, the construction speed is fast, and there is no need for large machinery, so manpower can be quickly deployed.

4. Low economic cost: As a temporary measure, its material and installation maintenance costs are much lower than those of building permanent sedimentation tanks or other structures.

Product Introduction:

Non Woven Silt Fence is a widely used temporary sediment control measure in civil engineering and construction sites. Its core structure is composed of permeable non-woven geotextiles sewn or nailed onto sturdy support columns (usually wooden or metal piles) to form a vertical filtering barrier.

The core working principle is that when turbid rainwater runoff containing sediment impacts the fence, non-woven geotextiles allow the water flow to pass slowly, but at the same time effectively intercept and filter suspended sediment particles in the water. Sediments are blocked upstream of the fence and gradually settle, preventing them from flowing out of the construction site and polluting the downstream drainage system, rivers, lakes, and natural ecological environment.

Feature

1. Material characteristics:

Main components: Usually made from polypropylene (PP) or polyester (PET) fibers through needle punching or thermal bonding processes.

Permeability: Having a specific permeability that allows water to pass through while retaining soil.

Strength and durability: It has a certain tensile strength and bursting strength, and can withstand the impact pressure of water flow and sediment.

UV treatment: High quality anti-seepage fabric will undergo anti UV treatment to extend its service life under sunlight exposure.

2. Structural design:

Standard height: Common sizes include 76cm (30 inches), 91cm (36 inches), and 107cm (42 inches) to meet the needs of different terrains and water flow rates.

Bottom reinforcement: usually equipped with a reinforcing rib (steel rope or reinforcement band) and a bottom flange, used to bury the bottom of the fence in the soil and fix it, preventing water flow from hollowing out and leaking from below.

Support pile: Wooden or T-shaped steel piles provide support at a certain distance (usually 1.5-2 meters) to ensure that the fence is upright.

3. Functional features:

Temporary: The design service life is usually 6 months to 1 year, which is sufficient to cover the construction period of most building projects.

Maintenance required: As the intercepted sediment increases, it needs to be regularly cleaned or replaced to maintain its effectiveness.

Product Parameters:

project | metric | ||||||||||

Nominal strength/(kN/m) | |||||||||||

6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |||

1 | Longitudinal and transverse tensile strength / (kN/m) ≥ | 6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |

2 | Maximum elongation at maximum load in longitudinal and transverse directions/% | 30~80 | |||||||||

3 | CBR top penetration strength /kN ≥ | 0.9 | 1.6 | 1.9 | 2.9 | 3.9 | 5.3 | 6.4 | 7.9 | 8.5 | |

4 | Longitudinal and transverse tearing strength /kN | 0.15 | 0.22 | 0.29 | 0.43 | 0.57 | 0.71 | 0.83 | 1.1 | 1.25 | |

5 | Equivalent aperture O.90(O95)/mm | 0.05~0.30 | |||||||||

6 | Vertical permeability coefficient/(cm/s) | K× (10-¹~10-), where K=1.0~9.9 | |||||||||

7 | Width deviation rate /% ≥ | -0.5 | |||||||||

8 | Unit area mass deviation rate /% ≥ | -5 | |||||||||

9 | Thickness deviation rate /% ≥ | -10 | |||||||||

10 | Thickness coefficient of variation (CV)/% ≤ | 10 | |||||||||

11 | Dynamic perforation | Puncture hole diameter/mm ≤ | 37 | 33 | 27 | 20 | 17 | 14 | 11 | 9 | 7 |

12 | Longitudinal and transverse fracture strength (grab method)/kN ≥ | 0.3 | 0.5 | 0.7 | 1.1 | 1.4 | 1.9 | 2.4 | 3 | 3.5 | |

13 | Ultraviolet resistance (Xenon arc lamp method) | Longitudinal and transverse strength retention rate% ≥ | 70 | ||||||||

14 | Ultraviolet resistance (fluorescence UV lamp method) | Longitudinal and transverse strength retention rate% ≥ | 80 | ||||||||

Product Applications:

1. Water conservancy engineering

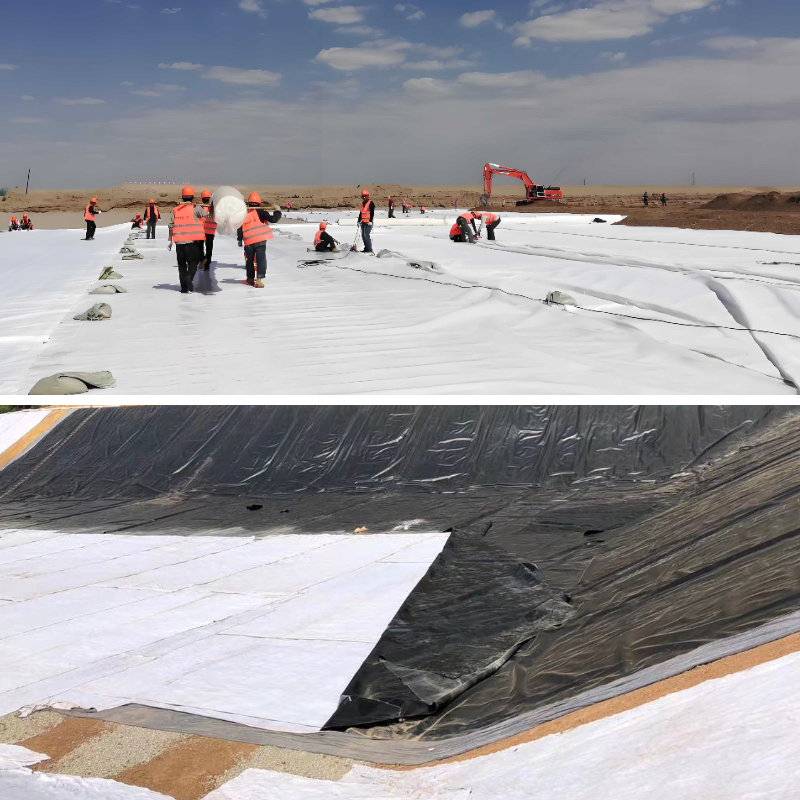

Dam and channel anti-seepage and protection: Geotextile can be laid on the upstream face of the dam, which can be combined with anti-seepage membrane to enhance the anti-seepage effect, while protecting the anti-seepage layer from damage by the upper soil or water flow; Laying geotextile in the channel can reduce the erosion of water flow on the slope and prolong the service life of the channel.

River regulation: used for the protection of river slopes to prevent soil erosion; After dredging or dredging the river channel, laying geotextile can isolate the newly filled material from the original soil to avoid mixing.

Reservoir engineering: The anti filter layer of the reservoir dam body prevents soil particles from flowing away with seepage, while ensuring smooth discharge of seepage and maintaining the stability of the dam body.

2. Transportation Engineering

Road and railway subgrade treatment: laid between the subgrade and the base layer, isolating soil materials of different particle sizes to prevent mixing of subgrade soil and base layer materials, and avoiding a decrease in base layer strength.

Road maintenance: When renovating old road surfaces, laying geotextiles can reduce the reflection cracks between new and old road surfaces and extend the service life of the road surface.

Airport runway: used for reinforcing and draining the runway base to ensure the stability of the runway structure.

3. Municipal engineering

Underground engineering: In subway and tunnel construction, it serves as a protective layer for waterproof layers or is used for initial support drainage to prevent groundwater infiltration from affecting the structure.

Drainage system: In urban rainwater pipes and leachate collection systems, it serves as a filtering layer to prevent sediment from blocking the pipes and ensure smooth water flow.

Landfill site:

Isolate garbage from surrounding soil and groundwater to prevent pollution from spreading.

As a drainage layer, collect leachate from garbage and export it to avoid accumulation of liquid.

Used for reinforcement in the covering layer to prevent soil loss.

4. Environmental Protection and Ecological Engineering

Soil and water conservation: Lay geotextiles in slope and mining reclamation areas, cooperate with vegetation planting, prevent soil erosion caused by rainwater erosion, and promote ecological restoration.

Artificial wetland: As an isolation or filtration layer at the bottom of the wetland, it prevents the loss of wetland substrate and purifies water quality.

Flood control and emergency rescue: During the flood season, it is used to quickly build embankments, block loopholes, and temporarily reinforce embankments using their anti-seepage and reinforcement characteristics.

5. Agriculture and Landscape Architecture

Irrigation system for farmland: used for anti-seepage and slope protection of irrigation channels, reducing water leakage and improving irrigation efficiency.

Landscape greening: Lay geotextile at the bottom of landscape water bodies and artificial lakes to prevent water infiltration and protect the anti-seepage layer from damage by plant roots.

6. Mining Engineering

The anti filter layer and isolation layer of the mine tailings dam prevent the loss of tailings particles and discharge seepage, ensuring the safety of the dam body; The foundation layer used for soil improvement and vegetation restoration during mining area reclamation.

The core application of geotextile is to use its combination of "permeability" and "mechanical properties" to select products of different materials and specifications according to specific engineering needs, in order to achieve functions such as filtration, drainage, isolation, and reinforcement, thereby improving the stability, durability, and environmental friendliness of the project.