Impermeable Geotextile Fabric

1.Strong impermeability: The coefficient of permeability is extremely low. For example, for HDPE geomembrane, it is ≤1×10⁻¹²cm/s. It can effectively block liquid leakage and is the first choice for projects with high impermeability requirements such as water conservancy projects and landfills.

2.Excellent corrosion resistance: It is made of polymer materials such as polyethylene (PE) and polyvinyl chloride (PVC). Its chemical properties are stable, and it can resist the erosion of chemical substances such as acids, alkalis, and salts.

3.Good aging resistance: Additives such as carbon black and antioxidants are added during production to enhance the ability to resist ultraviolet rays. Under normal use, the service life of HDPE geomembrane can reach more than 50 years.

4.Excellent flexibility: It has good flexibility and extensibility, can adapt to foundation deformation, and can still maintain the integrity of the structure in case of foundation settlement or displacement.

5.High puncture and tear resistance: It has a certain thickness and strength, can resist external impacts, and is not easily damaged in complex environments.

6.Good weather resistance: It can adapt to a wide temperature range, not brittle at -70°C and not softened at +60°C, and its performance is stable in different climatic environments.

Product Introduction:

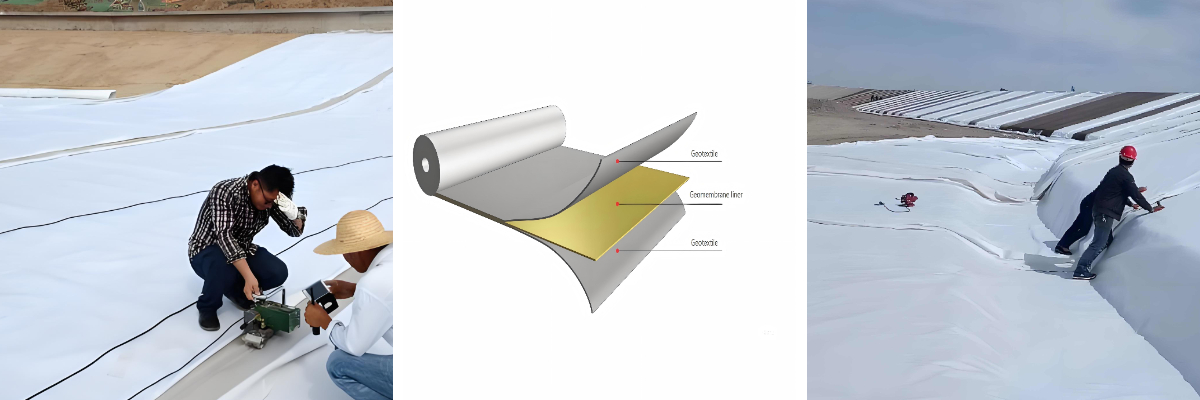

Impermeable Geotextile Fabric is an impermeable material composed of a geotextile and a geomembrane.

Structure: Usually, geotextiles are laminated on one or both sides of the geomembrane. The geomembrane plays a role in seepage prevention, while the geotextiles (such as non - woven geotextiles and woven geotextiles) serve functions like protection and reinforcement.

Classification: By structure, it can be divided into one - fabric - one - membrane, two - fabric - one - membrane, one - fabric - two - membranes, multiple - fabric - multiple - membranes, etc. The commonly seen ones are one - fabric - one - membrane and two - fabric - one - membrane. The width is generally 4 - 6m, and the weight is 200 - 1500g/m².

Performance feature

Seepage prevention property: Using plastic film as the seepage prevention base material, it has good seepage prevention performance and can effectively prevent water seepage.

Mechanical properties: Physical and mechanical performance indicators such as tensile strength, tear resistance, and bursting strength are high, with high strength, good elongation performance, and a large deformation modulus.

Corrosion Resistance: High - molecular materials are selected, and anti - aging agents are added in the production process. It is resistant to acids, alkalis, corrosion, and aging.

Others: It is lightweight, soft, easy to fold, and convenient for transportation and storage. The warp - knitted composite geomembrane also has the characteristic that the intersection points of the warp and weft do not bend and each is in a straight state.

Product Parameters:

project | metric | ||||||||

| Nominal fracture strength/(kN/m) | 5 | 7.5 | 10 | 12 | 14 | 16 | 18 | 20 | |

| 1 | Longitudinal and transverse fracture strength/(kN/m) ≥ | 5 | 7.5 | 10 | 12 | 14 | 16 | 18 | 20 |

| 2 | Longitudinal and transverse standard strength corresponding elongation/% | 30~100 | |||||||

| 3 | CBR top penetration strength /kN ≥ | 1.1 | 1.5 | 1.9 | 2.2 | 2.5 | 2.8 | 3 | 3.2 |

| 4 | Longitudinal and transverse tearing strength /kN ≥ | 0.15 | 0.25 | 0.32 | 0.4 | 0.48 | 0.56 | 0.62 | 0.7 |

| 5 | Peel strength/(N/cm)> | 6 | |||||||

| 6 | Vertical permeability coefficient/(cm/s) | As required by design or contract | |||||||

| 7 | Width deviation /% | -1 | |||||||

| project | film thickness /mm | ||||||||

| 0.2 | 0.3 | 0.4 | 0.5 | 0.6 | 0.7 | 0.8 | 1 | ||

| Resistant to static water pressure /MPa ≥ | One cloth, one membrane | 0.4 | 0.5 | 0.6 | 0.8 | 1 | 1.2 | 1.4 | 1.6 |

| Two cloth and one film | 0.5 | 0.6 | 0.8 | 1 | 1.2 | 1.4 | 1.6 | 1.8 | |

| Note: If the film thickness is between adjacent specifications in the table, the corresponding assessment index shall be calculated by linear interpolation; if it exceeds the range in the table, the assessment index shall be determined by negotiation between the supplier and the demander. | |||||||||

Product Applications:

Hydraulic Engineering

Dams: Used for dam seepage prevention, preventing seepage of the dam body, improving the stability of the dam, such as flood control dams of rivers, lakes and seas.

Reservoirs: Seepage prevention of the reservoir bottom and slopes, reducing reservoir seepage losses and extending the service life of the reservoir.

Channels: Seepage prevention of irrigation channels and drainage channels, reducing seepage during water conveyance and improving water resource utilization.

Reservoirs (small): Seepage treatment of various types of small reservoirs to ensure the quality and quantity of stored water.

Environmental Protection Projects

Landfill: The bottom and closure cover of the landfill are impermeable to prevent leachate from seeping and polluting groundwater and soil.

Sewage Treatment Pond: The sewage treatment pond is made impermeable to avoid sewage seepage from polluting the surrounding environment.

Waste Residue Treatment Site: Prevent harmful substances in waste residues from seeping out and polluting the surrounding ecological environment.

Traffic Engineering

Highways and Railways: Used for subgrade seepage prevention to prevent groundwater from affecting the stability of the subgrade. Application in expansive soil and collapsible loess areas can improve the foundation conditions; it can also be used for tunnel seepage prevention to prevent groundwater seepage from affecting the tunnel structure and operational safety.

Airport Runways: Seepage prevention of the runway foundation to ensure foundation stability and reduce runway damage caused by waterlogging, etc.

Agriculture and Aquaculture

Agriculture: Used for seepage prevention in agricultural irrigation ponds and pools to reduce water leakage losses.

Aquaculture: Used for seepage prevention in fish ponds, shrimp ponds, crab ponds and other aquaculture ponds to maintain water level and regulate water quality.

Construction Engineering

Basement: Waterproof the basement floor and side walls to prevent groundwater from seeping in and ensure the basement remains dry.

Roof: Waterproof the roof to prevent seepage and moisture, protecting the internal structure of the building.

Function Integration: Integration of anti-seepage, reinforcement, and protection. It is more tear-resistant and puncture-resistant than single geotextile membranes.

High Environmental Adaptability: Resistant to aging, corrosion, and extreme temperatures (-70℃~+60℃), suitable for different climatic and geological conditions.

Environmental Friendliness and Safety: The material is non-toxic, can prevent pollutant leakage, and protect water and soil resources.

High Cost-effectiveness: High construction efficiency, long service life, and low maintenance cost. It widely replaces traditional anti-seepage materials (such as concrete).