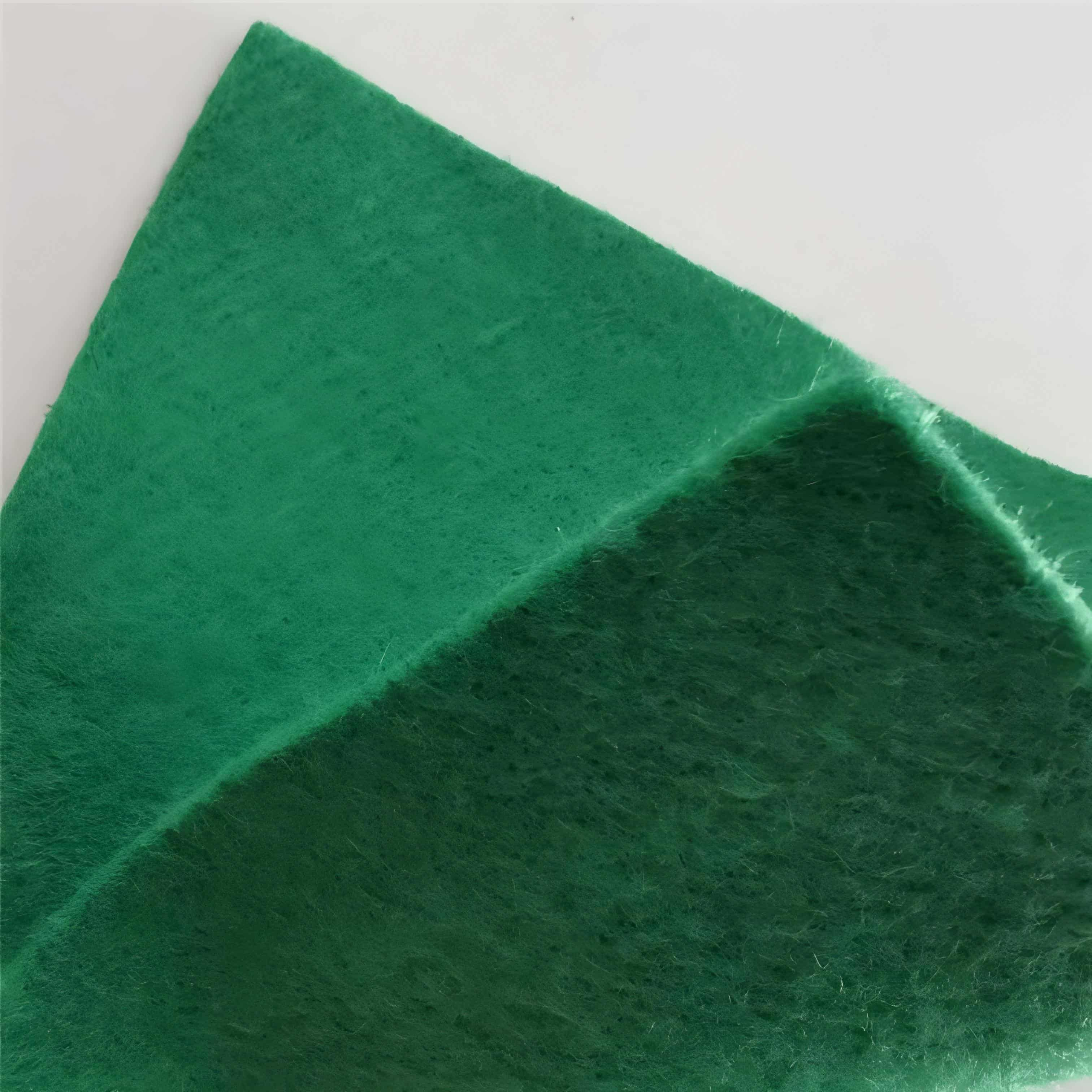

Geotextile Geofabric

1. Soil Reinforcement: High-strength fibers enhance soil shear resistance, disperse pressure, and prevent collapse, making it suitable for slopes, roadbeds, and other applications.

2. Filtration and Drainage: Precisely filters fine particles, allowing water to drain, preventing soil erosion and pipe bursts, and ensuring structural stability.

3. Isolation and Protection: Separates different materials to prevent mixing, reduce wear, extend the life of the project, and resist acid, alkali, and aging.

4. Easy Laying and Adaptability: The material is easily cut to fit complex terrain, ensuring fast installation and adaptability to a variety of project types, reducing costs.

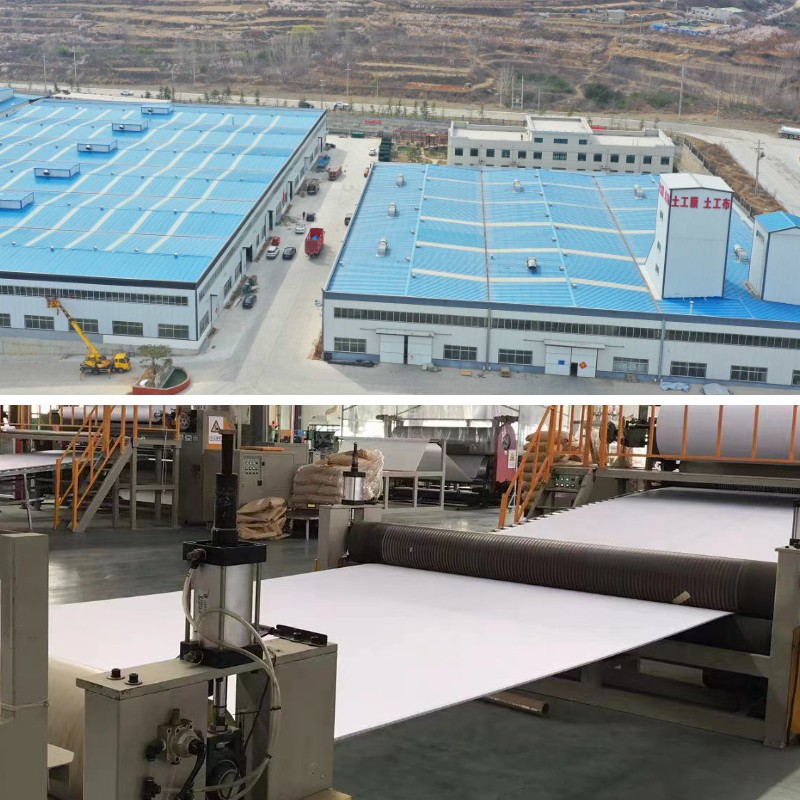

Products Introduction:

Geotextile geofabric is a multifunctional geosynthetic material made from polymers such as polypropylene (PP) and polyester (PET) through needle-punching (non-woven), weaving, or knitting. Some products undergo special treatments for UV protection, corrosion resistance, and flame retardancy. Its core functions in civil engineering are reinforcement, filtration, isolation, and protection. By optimizing soil structure, controlling water migration, and reducing material loss, it addresses challenges such as soil erosion, structural instability, drainage blockage, and short project lifespans. As a key supporting material for modern civil engineering, it is widely used in road, water conservancy, municipal engineering, mining, and other applications, providing an invisible support for improving project stability and cost-effectiveness.

Product Features:

1. High-strength reinforcement for enhanced structural load-bearing: Utilizing filament weaving or high-density needle punching, the fabric achieves longitudinal and transverse tensile strengths of 20-100 kN/m, with excellent tear and burst resistance. After installation, it forms a composite structure with the soil, effectively distributing loads and enhancing soil shear strength, mitigating subsidence and collapse caused by uneven pressure on roadbeds and slopes. It is particularly well-suited for complex engineering scenarios such as soft soil foundations and high fills.

2. Precise filtration and drainage, preventing loss and maintaining stability: The fabric's pore size (0.01-0.5mm) is scientifically designed to filter fine soil particles (such as clay and silt) from water flow, preventing them from forming cavities with water loss. It also allows rainwater and groundwater to penetrate freely, reducing pore water pressure in the soil, preventing problems such as piping and seepage damage, and ensuring the long-term stability of the project.

3. Isolation and protection, extending lifespan and reducing wear: It effectively separates materials of different grades (such as sand and clay, roadbed and foundation soil), preventing material mixing and degradation that could lead to structural performance degradation. It also isolates sharp particles from the main structure (such as pipes and walls), reducing friction and wear. Combined with anti-aging treatment, it withstands environmental damage from acids, alkalis, UV rays, and temperature fluctuations, extending the overall lifespan of the project.

4. Highly adaptable and easy to install, reducing costs and improving efficiency: Its flexible texture and lightweight (80-600g/m²) allow it to be cut and spliced to project contours (such as curved and zigzag shapes) without the need for complex equipment. It is suitable for a variety of applications, including road construction, water conservancy, and municipal engineering. Its rapid installation speed shortens construction time by 20%-40% compared to traditional materials, reducing labor and equipment costs.

Product Parameters:

project | metric | ||||||||||

Nominal strength/(kN/m) | |||||||||||

6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |||

1 | Longitudinal and transverse tensile strength / (kN/m) ≥ | 6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |

2 | Maximum elongation at maximum load in longitudinal and transverse directions/% | 30~80 | |||||||||

3 | CBR top penetration strength /kN ≥ | 0.9 | 1.6 | 1.9 | 2.9 | 3.9 | 5.3 | 6.4 | 7.9 | 8.5 | |

4 | Longitudinal and transverse tearing strength /kN | 0.15 | 0.22 | 0.29 | 0.43 | 0.57 | 0.71 | 0.83 | 1.1 | 1.25 | |

5 | Equivalent aperture O.90(O95)/mm | 0.05~0.30 | |||||||||

6 | Vertical permeability coefficient/(cm/s) | K× (10-¹~10-), where K=1.0~9.9 | |||||||||

7 | Width deviation rate /% ≥ | -0.5 | |||||||||

8 | Unit area mass deviation rate /% ≥ | -5 | |||||||||

9 | Thickness deviation rate /% ≥ | -10 | |||||||||

10 | Thickness coefficient of variation (CV)/% ≤ | 10 | |||||||||

11 | Dynamic perforation | Puncture hole diameter/mm ≤ | 37 | 33 | 27 | 20 | 17 | 14 | 11 | 9 | 7 |

12 | Longitudinal and transverse fracture strength (grab method)/kN ≥ | 0.3 | 0.5 | 0.7 | 1.1 | 1.4 | 1.9 | 2.4 | 3 | 3.5 | |

13 | Ultraviolet resistance (Xenon arc lamp method) | Longitudinal and transverse strength retention rate% ≥ | 70 | ||||||||

14 | Ultraviolet resistance (fluorescence UV lamp method) | Longitudinal and transverse strength retention rate% ≥ | 80 | ||||||||

Product Applications:

1. Road and Infrastructure Engineering: It is used in highway and railway roadbeds to separate the roadbed soil from the base layer of gravel and sand, preventing material mixing. It also enhances the roadbed's resistance to deformation, reducing settlement and cracking caused by vehicle loads. In conjunction with drainage systems, it accelerates the drainage of accumulated water in the roadbed, extending the road's service life.

2. Water Conservancy and River Management: It is used for slope protection in rivers and reservoirs, preventing soil loss caused by water erosion through filtration. It is used outside the anti-seepage layer of dams to protect the anti-seepage membrane from abrasion by sharp rocks. In channel linings, it isolates the lining material from the soil, ensuring efficient water flow.

3. Municipal and Environmental Engineering: It acts as a protective layer in the anti-seepage systems of municipal sewage treatment plants and landfills, separating the anti-seepage membrane from the backfill soil and reducing membrane damage. It is used for drainage filtration in underground pipeline corridors and foundation pits, preventing soil loss around the corridors and ensuring construction safety.

4. Mines and ecological restoration: In slope greening projects after mining, laying geotextiles can fix the surface soil, prevent rainwater erosion, and provide a stable base for vegetation growth. In tailings pond management, it acts as a filter layer to prevent tailings loss, while also channeling seepage and reducing the risk of dam failure.

Geotextile Geofabric, with its core advantages of reinforcement, filtration and drainage, isolation and protection, and high adaptability, is applicable across the entire civil engineering landscape, fundamentally addressing the challenges of traditional engineering projects, such as structural instability, short lifespan, and difficult maintenance. Its versatile design provides efficient solutions for applications ranging from roadbed reinforcement in road infrastructure to slope protection in water conservancy projects to soil stabilization in ecological restoration. Combining technical reliability with economic practicality, this product not only improves project quality and reduces safety hazards, but also streamlines construction processes and reduces long-term costs. It is an indispensable foundational material in modern civil engineering and plays a vital role in promoting efficient and green construction.