Geotextile Fabric Under Asphalt

1. Isolation and Anti-mixing: Separates the asphalt layer from the base material, preventing fine soil from upwelling and contaminating the asphalt and preventing pavement cracking.

2. Reinforcement and Anti-cracking: Enhances the structural integrity of the pavement, distributes vehicle loads, and reduces stress concentration in the asphalt layer leading to cracking.

3. Drainage and Moisture Control: Drains water from the base layer, preventing moisture retention and softening the roadbed, thereby extending the service life of the asphalt pavement.

4. Convenient Construction: Easy to lay, quickly adheres to the base layer, and is compatible with the asphalt paving process, without adding additional time.

Products Introduction:

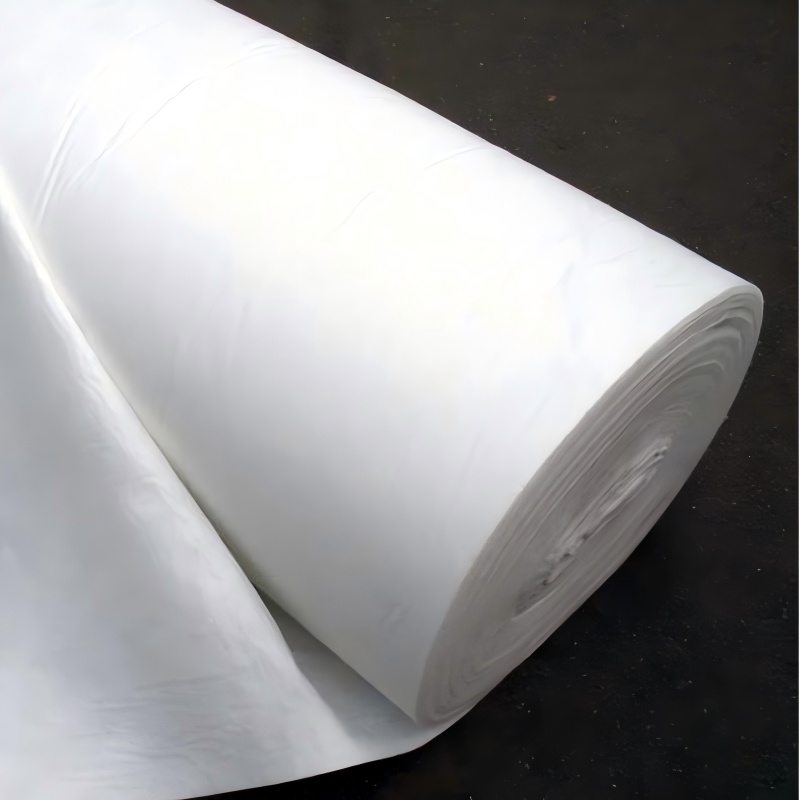

Geotextile Fabric Under Asphalt is a high-performance geosynthetic designed specifically for asphalt pavement structures. Made from polyester (PET) filament or polypropylene (PP) staple fiber, it is produced through needle-punched nonwoven or woven processes. Some products undergo anti-aging and high-temperature treatments to adapt to asphalt paving environments. Its core function is to be laid between the asphalt surface and the base layer (such as gravel or soil). By providing isolation and protection, reinforcement, and drainage and moisture control, it addresses the problem of premature failure of asphalt pavements caused by base layer contamination, load stress concentration, and moisture erosion, thereby extending the pavement's service life. It is a key supporting material for enhancing the structural stability of asphalt pavements and is widely used in asphalt paving projects such as highways, municipal roads, and parking lots.

Product Features:

1. Highly Effective Isolation, Anti-Pollution and Anti-Slippage: The fabric features fine and uniform pores (0.05-0.2mm), effectively separating the asphalt surface layer from the underlying base material. This prevents fine soil and dust in the base layer from rising with vehicle loads and contaminating the asphalt binder, preventing "sticking and slipping" between the asphalt layer and the base layer. It also prevents asphalt from seeping into the base layer during high-temperature paving, ensuring the structural independence of the surface layer and base layer, and reducing cracking and buckling caused by material mixing.

2. Directed Reinforcement, Load Distribution, and Fatigue Resistance: Woven with high-strength fibers, it achieves longitudinal and transverse tensile strengths of 10-30kN/m and excellent tear resistance. After installation, it forms a "composite load-bearing system" with the asphalt layer and base layer, distributing stress generated by vehicle loads and reducing the risk of fatigue cracking in the asphalt surface layer caused by long-term, repetitive loading. It is particularly suitable for heavy-duty traffic sections (such as freight corridors and port roads).

3. Drainage and moisture prevention, protecting the stability of the base layer: Excellent water permeability (permeability coefficient ≥ 1×10⁻³cm/s) allows for rapid drainage of accumulated water (e.g., rainwater infiltration and capillary rise of groundwater), preventing water retention and softening of the base soil, thus preventing road subgrade settlement and resulting road surface depressions and cracking. It also reduces water erosion of the base aggregate, maintaining the structural integrity of the base layer.

4. Temperature-resistant and adaptable, enabling easy construction and reduced costs: Treated to withstand high temperatures (≥180°C), it withstands the high temperatures of asphalt paving without deformation or degradation. Its flexible texture (thickness 1-3mm) and lightweight (100-300g/m²) allow it to quickly conform to uneven base surfaces, requiring only overlapping joints (width ≥ 15cm) for paving. It is compatible with asphalt paver operations and does not increase construction time. Compared to traditional materials such as fiberglass grids, construction costs are reduced by 15%-20%.

Product Parameters:

project | metric | ||||||||||

Nominal strength/(kN/m) | |||||||||||

6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |||

1 | Longitudinal and transverse tensile strength / (kN/m) ≥ | 6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |

2 | Maximum elongation at maximum load in longitudinal and transverse directions/% | 30~80 | |||||||||

3 | CBR top penetration strength /kN ≥ | 0.9 | 1.6 | 1.9 | 2.9 | 3.9 | 5.3 | 6.4 | 7.9 | 8.5 | |

4 | Longitudinal and transverse tearing strength /kN | 0.15 | 0.22 | 0.29 | 0.43 | 0.57 | 0.71 | 0.83 | 1.1 | 1.25 | |

5 | Equivalent aperture O.90(O95)/mm | 0.05~0.30 | |||||||||

6 | Vertical permeability coefficient/(cm/s) | K× (10-¹~10-), where K=1.0~9.9 | |||||||||

7 | Width deviation rate /% ≥ | -0.5 | |||||||||

8 | Unit area mass deviation rate /% ≥ | -5 | |||||||||

9 | Thickness deviation rate /% ≥ | -10 | |||||||||

10 | Thickness coefficient of variation (CV)/% ≤ | 10 | |||||||||

11 | Dynamic perforation | Puncture hole diameter/mm ≤ | 37 | 33 | 27 | 20 | 17 | 14 | 11 | 9 | 7 |

12 | Longitudinal and transverse fracture strength (grab method)/kN ≥ | 0.3 | 0.5 | 0.7 | 1.1 | 1.4 | 1.9 | 2.4 | 3 | 3.5 | |

13 | Ultraviolet resistance (Xenon arc lamp method) | Longitudinal and transverse strength retention rate% ≥ | 70 | ||||||||

14 | Ultraviolet resistance (fluorescence UV lamp method) | Longitudinal and transverse strength retention rate% ≥ | 80 | ||||||||

Product Applications:

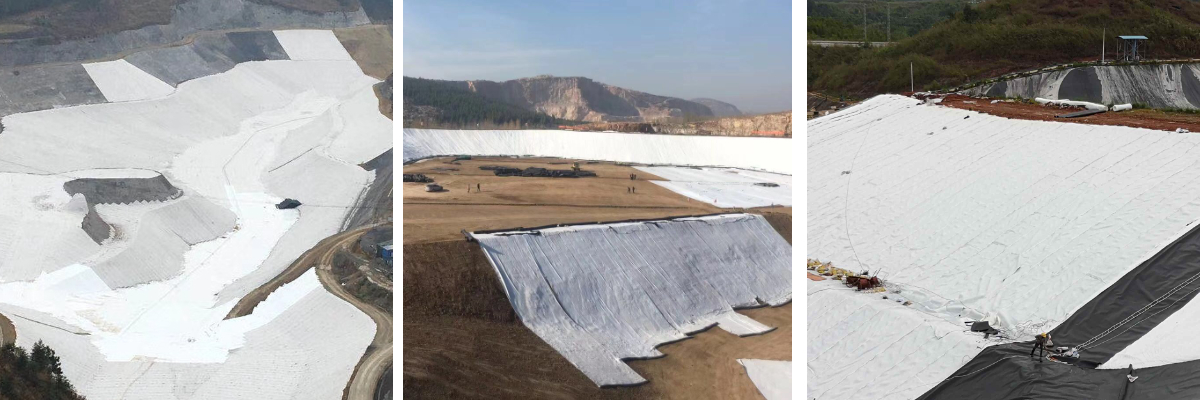

1. High-Grade Highway Asphalt Pavement: This pavement is laid between the asphalt subgrade and the water-stable base layer on expressways and first-class highways. It focuses on addressing base layer contamination and load stress issues under heavy traffic, reducing rutting and cracking, and extending the road overhaul cycle (by 3-5 years). It is suitable for long-distance trunk highway projects.

2. Municipal Roads and Alleys: This pavement is used for asphalt paving on urban main and secondary roads, as well as residential streets. Its drainage and moisture-proofing properties address frequent rainwater infiltration during the rainy season, preventing pavement depressions caused by softening of the base layer. It also isolates fine soil in the base layer, reduces "sanding," and improves the durability of municipal roads.

3. Parking Lots and Plazas: This pavement is laid beneath the asphalt surface of large parking lots and commercial plazas. It accommodates the localized loads generated by frequent vehicle starts and stops. Its reinforcement reduces cracks caused by stress concentration in the pavement, while also channeling surface water to prevent damage to the base layer caused by water accumulation in parking lots.

4. Renovation of old roads: In the “white to black” (cement pavement to asphalt pavement) or overlay project of old asphalt pavement, it is laid between the old pavement and the new asphalt layer to isolate the loose particles of the old pavement from the new asphalt, prevent reflective cracks, and at the same time enhance the integrity of the old and new structural layers, reducing the later maintenance costs of the renovation project.

Geotextile Fabric Under Asphalt addresses the core challenges of asphalt pavement structures. Leveraging its core advantages of "isolation and anti-fouling, reinforcement and crack resistance, drainage and moisture resistance, and heat resistance and ease of construction," it provides full-life structural protection for asphalt pavements. Whether used in heavy-duty traffic scenarios on highways or for daily traffic on municipal roads, its scientific performance design effectively extends pavement life and reduces maintenance costs. Combining functionality with affordability, the product is easy to install and compatible with various asphalt paving processes. It is an ideal supporting material for enhancing structural stability and achieving the "long life, low cost" goals of modern pavement projects, driving the development of more durable and economical asphalt pavement construction.