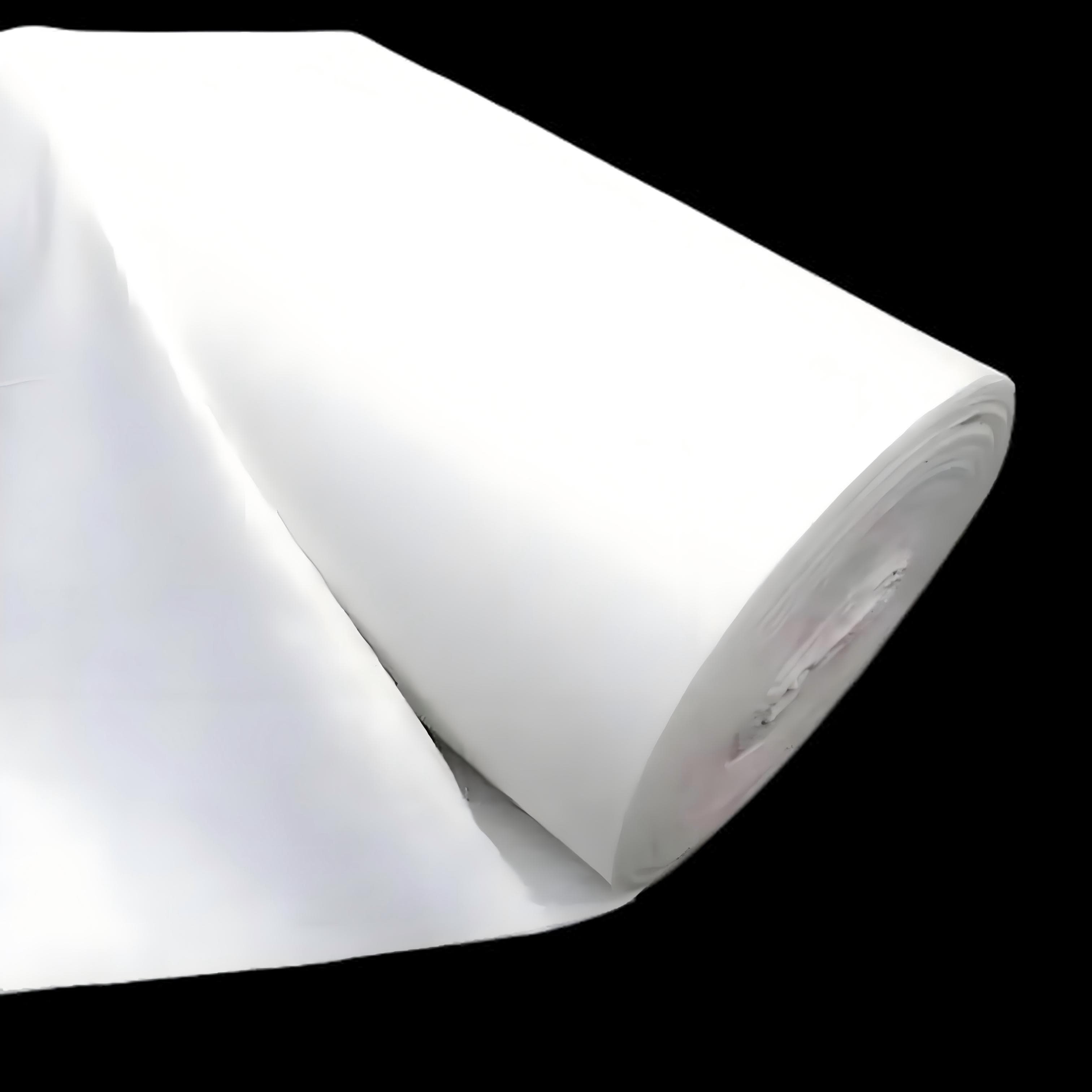

Non Woven Fabric Geotextile

1. Dual advantages of filtration and drainage: The three-dimensional porous structure quickly guides water, while intercepting fine soil to prevent blockage, and is suitable for multi scenario water control.

2. Durable and resistant to manufacturing: resistant to high and low temperatures, corrosion-resistant, with stable performance for many years of outdoor use, reducing maintenance costs.

3. Easy to lay and labor-saving: The material is soft and can fit irregular terrain. It can be manually cut and laid, resulting in high construction efficiency.

4. Environmental safety: Non toxic materials with no pollutant release, partially biodegradable, suitable for ecological engineering needs.

Products Introduction:

Non Woven Fabric Geotextile is a core basic category in geosynthetic material systems. It uses high molecular weight fibers such as polypropylene (PP) and polyester (PET) as raw materials, and randomly interweaves and solidifies the fibers through processes such as needle punching, thermal bonding, and spunbonding, without the need for traditional weaving steps of warp and weft yarns. Its core functions revolve around the four dimensions of "filtration, drainage, isolation, and protection". With its unique three-dimensional porous structure and flexible characteristics, it plays a key role in "preventing soil erosion, draining excess water, and protecting the integrity of structural layers" in civil engineering.

Compared to woven geotextiles that focus on high-strength reinforcement, non-woven geotextiles pay more attention to the balance between functionality and scene adaptability, especially in scenarios that require precise filtering, fitting complex terrain, or cost control. They have significant advantages and are widely used in fields such as water conservancy, transportation, municipal government, agriculture, and environmental protection. They are a basic protective material that balances efficiency and economy in various engineering projects.

Product Features:

1. Efficient filtration and drainage, anti blocking and stable

Fibers are randomly interwoven to form uniform three-dimensional pores (pore size 0.05-0.3mm), with a retention rate of over 95% for fine soil particles. This can effectively prevent the loss of fine soil particles with water flow in the base layer and avoid blockages in drainage systems such as infiltration ditches and drainage pipes; At the same time, the pores are interconnected with a permeability coefficient of ≥ 1 × 10 ⁻ cm/s, which can quickly divert rainwater, groundwater or leachate, reduce the pore water pressure of the soil, prevent structural instability caused by soil softening due to accumulated water, and adapt to scenarios with high filtration requirements such as landfill reverse filtration and river bank slope protection.

2. Flexible and snug fit, suitable for complex terrains

Soft texture and good ductility (fracture elongation of 15% -50%), can naturally adhere to irregular base layers such as potholes, slopes, and curved ditches, without blind spots for laying; Lightweight (50-400g/m ²), easy to cut, no need for professional large equipment, manual laying can be completed, and even fast construction can be carried out in narrow spaces or temporary sites, solving the pain points of traditional rigid protective materials that are difficult to fit and prone to cracking. It is suitable for limited construction conditions such as rural roads and courtyard renovations.

3. Weather resistant and corrosion-resistant, long-lasting and durable

The raw materials have undergone anti UV, anti acid and alkali, and anti biodegradation treatments, and can be stably used in extreme environments ranging from -30 ℃ to 70 ℃, resisting soil corrosion, microbial decomposition, and outdoor sun and rain exposure; In ordinary soil or water environments, the service life can reach 5-10 years, and it can also maintain stable performance for 3-5 years in complex environments such as landfills, reducing the frequency and cost of later maintenance and replacement.

4. Eco friendly, safe and compatible

Using non-toxic and harmless polymer materials, there are no harmful emissions during the production process, and no pollutants are released after installation. It can directly contact soil, groundwater, and vegetation roots without affecting plant growth, and is suitable for high environmental protection scenarios such as ecological slopes, roof greening, and agricultural water conservancy; Some biodegradable models can naturally decompose into harmless substances at the end of their service life, reducing the burden of engineering waste on the environment.

5. Cost economy and efficient construction

The production process is simplified, the utilization rate of raw materials is high, and the unit price is only 60% -80% of that of woven geotextiles; No heavy machinery is required for laying, and manual overlap (overlap width ≥ 10cm) can be completed. The construction efficiency is 2-3 times higher than traditional sand and gravel filter layers, especially suitable for large-scale projects (such as agricultural drainage and irrigation, municipal road base protection), which can significantly reduce the overall project cost.

Product Parameters:

project | metric | ||||||||||

Nominal strength/(kN/m) | |||||||||||

6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |||

1 | Longitudinal and transverse tensile strength / (kN/m) ≥ | 6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |

2 | Maximum elongation at maximum load in longitudinal and transverse directions/% | 30~80 | |||||||||

3 | CBR top penetration strength /kN ≥ | 0.9 | 1.6 | 1.9 | 2.9 | 3.9 | 5.3 | 6.4 | 7.9 | 8.5 | |

4 | Longitudinal and transverse tearing strength /kN | 0.15 | 0.22 | 0.29 | 0.43 | 0.57 | 0.71 | 0.83 | 1.1 | 1.25 | |

5 | Equivalent aperture O.90(O95)/mm | 0.05~0.30 | |||||||||

6 | Vertical permeability coefficient/(cm/s) | K× (10-¹~10-), where K=1.0~9.9 | |||||||||

7 | Width deviation rate /% ≥ | -0.5 | |||||||||

8 | Unit area mass deviation rate /% ≥ | -5 | |||||||||

9 | Thickness deviation rate /% ≥ | -10 | |||||||||

10 | Thickness coefficient of variation (CV)/% ≤ | 10 | |||||||||

11 | Dynamic perforation | Puncture hole diameter/mm ≤ | 37 | 33 | 27 | 20 | 17 | 14 | 11 | 9 | 7 |

12 | Longitudinal and transverse fracture strength (grab method)/kN ≥ | 0.3 | 0.5 | 0.7 | 1.1 | 1.4 | 1.9 | 2.4 | 3 | 3.5 | |

13 | Ultraviolet resistance (Xenon arc lamp method) | Longitudinal and transverse strength retention rate% ≥ | 70 | ||||||||

14 | Ultraviolet resistance (fluorescence UV lamp method) | Longitudinal and transverse strength retention rate% ≥ | 80 | ||||||||

Product Applications:

1. Water conservancy and ecological protection engineering

River bank slope protection: laid on the surface of the bank slope or below the ecological gabion, intercepting soil particles to prevent soil erosion caused by water flow, while diverting rainwater to maintain the stability of the bank slope; Combined with vegetation planting, it can achieve a dual effect of "protection+ecological restoration", suitable for the reinforcement and renovation of small and medium-sized rivers and ponds.

Anti filtration of reservoirs and dams: used around the back slope or seepage ditch of dams to filter seepage from the dam body, prevent the loss of fine soil, avoid hidden dangers such as piping and landslides, and ensure the long-term safe operation of reservoirs and dams.

2. Transportation and Municipal Engineering

Road base protection: laid between the subgrade and pavement base of highways and rural roads, isolating soil materials of different gradations (such as sand, gravel, and clay) to prevent pavement cracking caused by mixing; At the same time, it can divert the accumulated water in the roadbed, reduce the softening of the base layer, extend the service life of the road, and adapt to the construction and maintenance of low-grade highways and municipal streets and alleys.

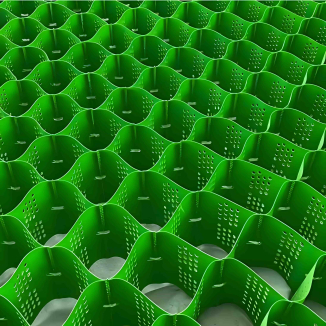

Parking lot and square ground: laid on asphalt or cement ground base to filter fine soil particles and avoid depressions on the ground due to soil erosion; Buffer the stress generated by vehicle loads, reduce ground cracks, and adapt to light load scenarios such as residential parking lots and municipal squares.

3. Environmental Protection and Waste Management Engineering

Landfill filter layer: laid above the anti-seepage membrane of the landfill or around the leachate collection ditch to filter impurities in the leachate and prevent blockage of the collection pipeline; Simultaneously isolate garbage from surrounding soil, reduce the risk of pollutant diffusion, and ensure that the landfill meets environmental standards.

Sewage treatment plant auxiliary: used at the bottom or periphery of oxidation ponds and infiltration filters in sewage treatment plants to isolate sewage from soil and prevent sewage infiltration from polluting groundwater; Filter sediment in water to maintain the operational efficiency of treatment facilities.

4. Agricultural and Horticultural Engineering

Irrigation system for farmland: wraps around the irrigation channels and inner walls of drainage ditches, filters sediment in the water flow, prevents channel blockage, and reduces the loss of irrigation water resources; Simultaneously protecting the soil on the canal wall from erosion, extending the service life of drainage and irrigation facilities, and adapting to agricultural water conservancy renovation projects.

Horticulture and planting containers: After cutting, they are laid at the bottom of flower pots and planting boxes, replacing traditional mesh to filter out excess water and prevent plant root rot. At the same time, they trap soil particles in the pot to avoid soil spillage during watering, making them suitable for home gardening and greenhouse seedling cultivation scenarios.

5. Temporary and emergency engineering

Temporary construction access road: laid on the base of the access road to enhance the bearing capacity of the temporary road surface, prevent mud and vehicle sinking caused by vehicle rolling, and can be recycled and reused after the project is completed, reducing the cost of temporary construction.

Emergency flood prevention and rescue: After a flood disaster, quickly install damaged parts of riverbanks and roadbeds to temporarily prevent soil erosion, divert accumulated water, buy time for subsequent repair work, and adapt to emergency rescue scenarios.

Non Woven Fabric Geotextile takes "efficient filtration and drainage, flexible adaptation, ecological protection, and economic efficiency" as its core advantages, accurately solving the multiple needs of "loss prevention, drainage, cost reduction, and ecological protection" in civil engineering. Whether it is slope protection in water conservancy projects, grassroots reinforcement of municipal roads, or green construction of ecological projects, reliable protection solutions can be provided through flexible performance and convenient construction.

Compared to other geotextiles, non-woven geotextiles excel in balancing functionality and economy - meeting the core requirements of filtration and isolation in engineering, reducing project investment through low cost and high efficiency, while also considering ecological and environmental protection needs. They are an ideal basic material for "multi scenario adaptation and full cycle reliability" in modern civil engineering. Its widespread application not only promotes the development of engineering construction towards a more efficient and green direction, but also provides strong support for people's livelihood fields such as water resource protection and ecological restoration, and has significant engineering value and social significance.