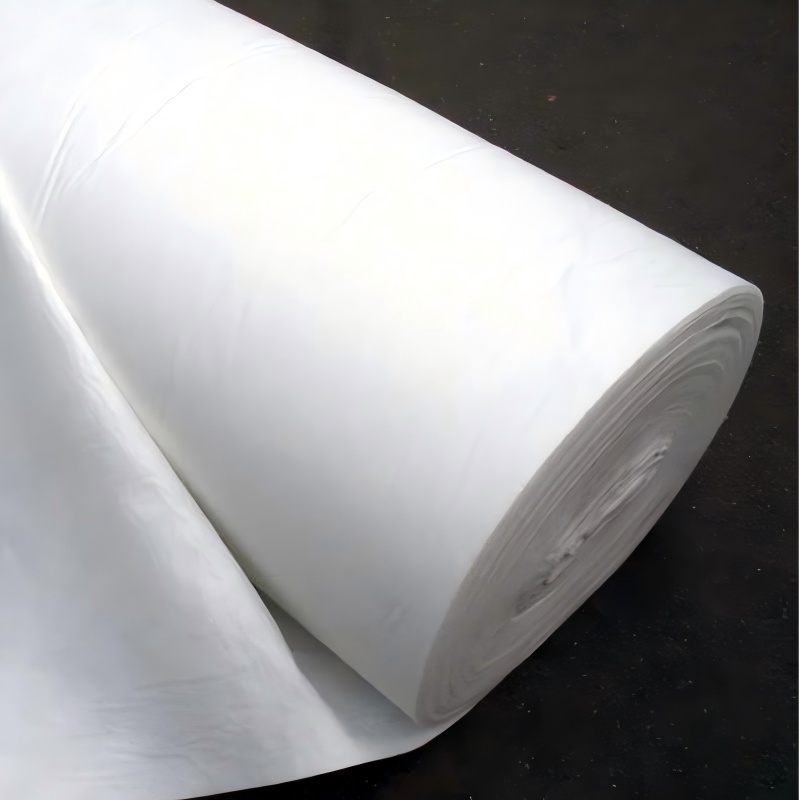

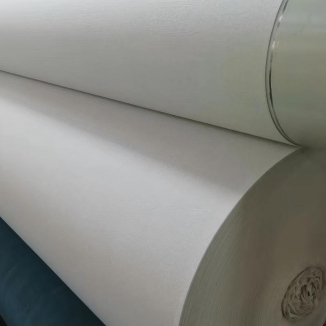

Needle Punched Geotextile Fabric

1. High strength and durability: high tensile strength, tear resistance, burst strength, corrosion resistance, acid and alkali resistance, resistance to microorganisms and insect infestations, long service life.

2. Permeability and Filtration: While allowing water to pass smoothly, it can effectively prevent excessive loss of soil particles, prevent clogging, and maintain structural stability.

3. Isolation function: It can effectively separate soil layers of different properties, prevent them from mixing with each other, and maintain their respective design functions.

4. Drainage and water guiding function: It can form a good drainage channel in its plane to discharge excess liquids and gases from the soil.

5. Reinforcement effect: disperses loads, improves the shear strength of soil, enhances the bearing capacity of soft foundation, and limits the lateral displacement of soil.

Product Introduction:

Needle Punched Geotextile Fabric is a permeable geosynthetic material made from synthetic fibers (such as polyester, polypropylene, nylon, etc.) or natural fibers through processes such as needle punching, weaving, weaving, and hot melting. It is one of the most widely used categories in geosynthetic materials, mainly used in geotechnical engineering, water conservancy engineering, transportation engineering and other fields, playing a role in filtration, drainage, isolation, reinforcement and other functions.

Classification

According to the manufacturing process, geotextiles can be divided into three categories, each with different characteristics and application scenarios:

1. Non woven geotextile (needle punched/hot melt): It is made by randomly arranging fibers and bonding them by needle punching or hot melt. It has good breathability and strong filtration, suitable for drainage and filtration, such as the filtration layer in hydraulic engineering.

2. Weaving geotextile (woven/woven): made by interweaving warp and weft yarns, with high strength and stable structure, suitable for reinforcement and isolation, such as the reinforcement of highway roadbeds.

3. Composite geotextile: Combining non-woven and weaving processes (such as "non-woven+woven"), it has both permeability and high strength, and is suitable for complex engineering scenarios (such as the combination of anti-seepage and drainage in landfills).

Feature

In addition to the above advantages, geotextiles also have the following core characteristics:

1. Multifunctionality

It can be designed according to different processes (needle punching, weaving, weaving, etc.) and materials to achieve various functions such as filtration, drainage, isolation, reinforcement, and protection, meeting the needs of different engineering scenarios. For example:

Needle punched non-woven geotextiles have good water permeability and are suitable for filtration and drainage;

Woven geotextile has high strength and is suitable for reinforcement and isolation.

2. Strong adaptability

It can be used in various environments such as high and low temperatures (-40 ℃ to 80 ℃), humidity, salt alkali, etc., and has low requirements for the flatness of the base layer. It can be attached to irregular surfaces.

3. Good overall integrity

It can be assembled through sewing, hot melt welding, and other methods to form a continuous and complete anti-seepage or reinforcement layer, avoiding the impact of local damage on the overall project quality.

Product Parameters:

project | metric | ||||||||||

Nominal strength/(kN/m) | |||||||||||

6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |||

1 | Longitudinal and transverse tensile strength / (kN/m) ≥ | 6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |

2 | Maximum elongation at maximum load in longitudinal and transverse directions/% | 30~80 | |||||||||

3 | CBR top penetration strength /kN ≥ | 0.9 | 1.6 | 1.9 | 2.9 | 3.9 | 5.3 | 6.4 | 7.9 | 8.5 | |

4 | Longitudinal and transverse tearing strength /kN | 0.15 | 0.22 | 0.29 | 0.43 | 0.57 | 0.71 | 0.83 | 1.1 | 1.25 | |

5 | Equivalent aperture O.90(O95)/mm | 0.05~0.30 | |||||||||

6 | Vertical permeability coefficient/(cm/s) | K× (10-¹~10-), where K=1.0~9.9 | |||||||||

7 | Width deviation rate /% ≥ | -0.5 | |||||||||

8 | Unit area mass deviation rate /% ≥ | -5 | |||||||||

9 | Thickness deviation rate /% ≥ | -10 | |||||||||

10 | Thickness coefficient of variation (CV)/% ≤ | 10 | |||||||||

11 | Dynamic perforation | Puncture hole diameter/mm ≤ | 37 | 33 | 27 | 20 | 17 | 14 | 11 | 9 | 7 |

12 | Longitudinal and transverse fracture strength (grab method)/kN ≥ | 0.3 | 0.5 | 0.7 | 1.1 | 1.4 | 1.9 | 2.4 | 3 | 3.5 | |

13 | Ultraviolet resistance (Xenon arc lamp method) | Longitudinal and transverse strength retention rate% ≥ | 70 | ||||||||

14 | Ultraviolet resistance (fluorescence UV lamp method) | Longitudinal and transverse strength retention rate% ≥ | 80 | ||||||||

Product Applications:

1. Water conservancy engineering:

Embankment and riverbank: filter layer, drainage layer (to prevent soil erosion), cushion layer under slope protection.

Channels and reservoirs: anti-seepage system protective layer at the bottom of the reservoir and channel.

Marine construction: soft foundation treatment, coastal erosion prevention.

2. Transportation Engineering:

Highway and railway: an isolation layer between the roadbed and ballast to prevent soft soil from rising; Simultaneously serving as reinforcement and drainage, extending the lifespan of the road.

Airport runway: stable foundation, dispersed load.

Parking lot: prevent the ground from sinking and cracking due to insufficient bearing capacity.

3. Environmental engineering:

Landfill site: one of the core materials. Used for protective layer (preventing HDPE anti-seepage membrane from being punctured), leachate collection and drainage layer, and filtration layer.

Wastewater treatment plants and artificial wetlands: used as filtration media and foundation layers.

4. Construction project:

Foundation treatment: reinforce soft soil foundation.

Basement waterproofing: used for the outer side of waterproofing membrane, which not only protects the waterproof layer but also plays a drainage role.

Roof garden: serving as an isolation and filtering layer.

5. Other fields:

Agriculture: used for drainage and weed control.

Landscape greening: used for lawn drainage and isolation.

Military engineering: Quickly laying temporary roads and reinforcing fortifications.

Geotextile, as a new type of geotechnical engineering material, has become an indispensable part of modern infrastructure construction due to its significant advantages of multifunctionality, efficiency, economy, and environmental protection. It is like a "smart fabric" hidden under roads, dams, and garbage dumps, silently playing a key role in reinforcement, isolation, drainage, filtration, and protection, greatly improving the quality, safety, and durability of the project.