Geomembran 500 Micron

1. Excellent waterproof performance: It can effectively prevent water infiltration and ensure water stability, such as maintaining water levels in water conservancy facilities such as pools and fish ponds.

2. Highly durable: can withstand extreme weather and complex environments, resist ultraviolet radiation and chemical corrosion, significantly extend service life, and reduce replacement frequency.

3. Good tear resistance: The 500 micron thickness design ensures good performance under compression, reducing the risk of damage and ensuring integrity during use.

4. Environmentally friendly material: The HDPE material used is recyclable and meets modern environmental standards, promoting sustainable development and being environmentally friendly.

5. Easy installation: It can be flexibly cut according to the shape and size of different pools, simplifying the installation process, and is suitable for both small and large projects.

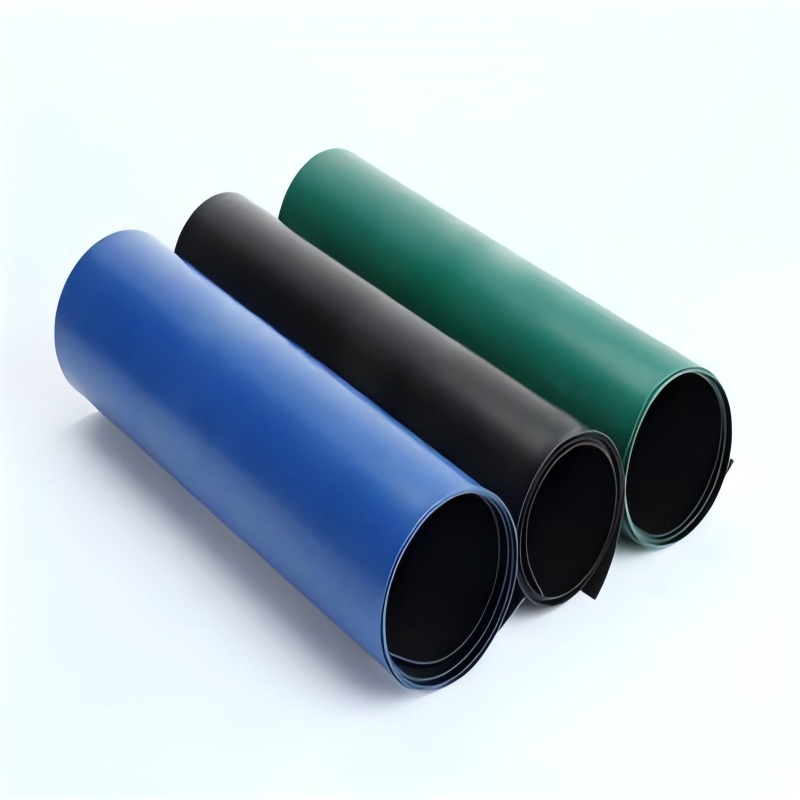

Products Introduction:

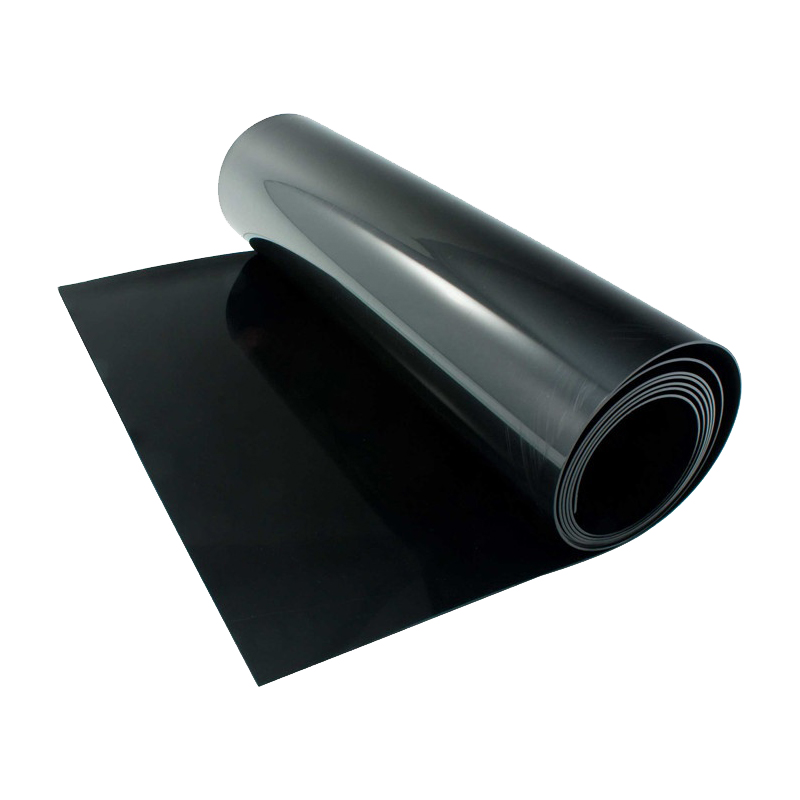

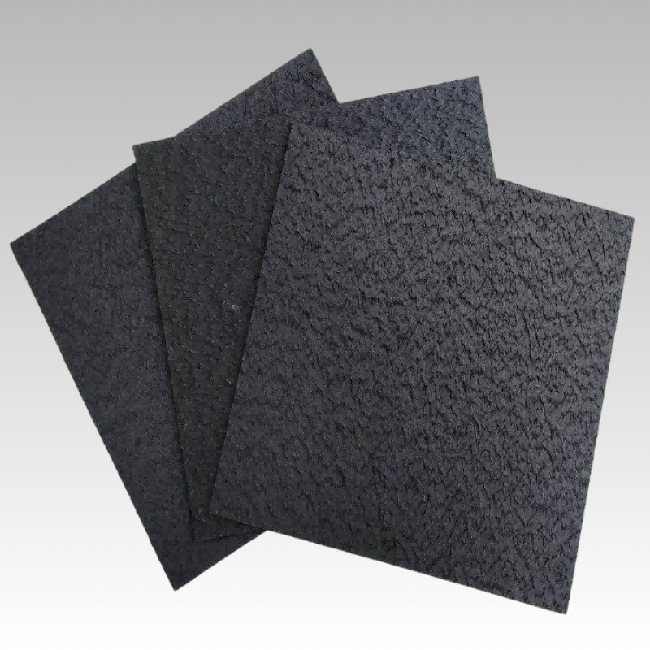

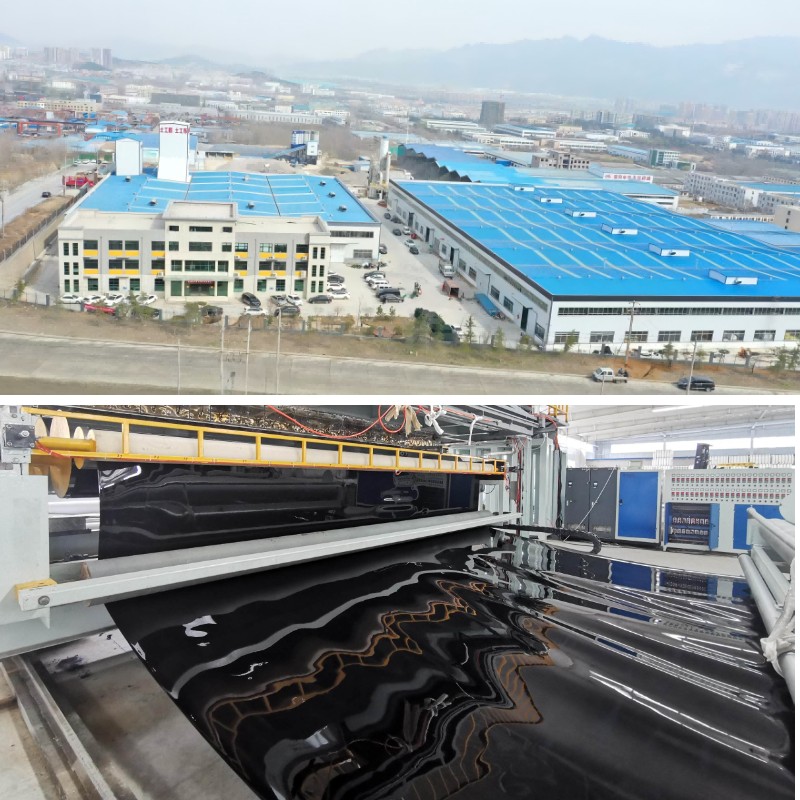

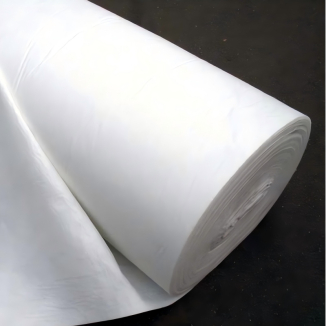

Geomembrane 500 Micron is a high-performance geomembrane product, with high-density polyethylene (HDPE) as its core material. Made through advanced production processes, with a thickness of 500 microns, it stands out among numerous geomembrane products and provides reliable solutions for various engineering applications. This type of geomembrane is widely used in project scenarios that require waterproofing, anti-seepage, and isolation, and is a key material to ensure engineering quality and safety.

Product Features:

1. Excellent waterproof performance: Geomembrane 500 Micron has a tight molecular structure, forming an efficient waterproof barrier that can effectively prevent water infiltration. In water conservancy facilities such as reservoirs and irrigation channels, water levels can be accurately maintained to avoid unnecessary loss of water resources and ensure water stability.

2. Highly durable: The HDPE material used has extremely strong resistance to environmental erosion and can withstand extreme weather conditions such as high temperature, low temperature, and humidity. At the same time, it has excellent resistance to corrosion from ultraviolet radiation and common chemicals, greatly extending the service life of the product and reducing the cost and trouble caused by frequent replacement.

3. Good tear resistance: The 500 micron thickness design endows the product with excellent physical strength, and performs excellently in complex stress environments such as compression and tension. Even in the event of accidental collisions during transportation and laying, or under certain pressure during use, it can significantly reduce the risk of damage and ensure integrity during use.

4. Environmentally friendly materials: HDPE material is a recyclable and environmentally friendly material that meets the strict standards of modern society for sustainable development and environmental protection. In projects using Geomembrane 500 Micron, it will not cause pollution to the surrounding environment and help various projects achieve green environmental goals.

5. Easy installation: The product has a relatively soft texture and can be flexibly cut according to the shape and size of different pools, ponds, or other engineering facilities. Whether it is a small private project or a large public project, it can simplify the installation process, reduce construction difficulty and time costs.

Product Parameters:

| Metric | ASTM | unit | Test value | Minimum test frequency | ||||||

| test method | 0.75 mm | 1.00 mm | 1.25 mm | 1.50 mm | 2.00 mm | 2.50mm | 3.00 mm | |||

| Minimum average thickness | D5199 | mm | 0.75 | 1 | 1.25 | 1.5 | 2 | 2.5 | 3 | Per volume |

| Minimum value (any one of 10) | -10% | -10% | -10% | -10% | -10% | -10% | -10% | |||

| minimum density | D 1505/D 792 | g/cm3 | 0.94 | 0.94 | 0.94 | 0.94 | 0.94 | 0.94 | 0.94 | 90,000 kg |

| Minimum average tensile performance (1) | D638 Type IV | |||||||||

| Breakage strength, | N/mm | 20 | 27 | 33 | 40 | 53 | 67 | 80 | 9,000 kg | |

| yield strength | N/mm | 11 | 15 | 18 | 22 | 29 | 37 | 44 | ||

| Strain extension, | % | 700 | 700 | 700 | 700 | 700 | 700 | 700 | ||

| yield extension | % | 12 | 12 | 12 | 12 | 12 | 12 | 12 | ||

| Minimum strength of right-angle tear | D 1004 | N | 93 | 125 | 156 | 187 | 249 | 311 | 374 | 20,000 kg |

| Minimum puncture strength | D4833 | N | 240 | 320 | 400 | 480 | 640 | 800 | 960 | 20,000 kg |

| Constant tensile load stress cracking (2) | D5397 | hour | 300 | 300 | 300 | 300 | 300 | 300 | 300 | Based on GRI GM-10 |

| Carbon black content | D 1603(3) | % | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 9,000 kg |

| Carbon black dispersion | D5596 | Note (4) | Note (4) | Note (4) | Note (4) | Note (4) | Note (4) | Note (4) | 20,000 kg | |

| Oxygen induction time (OIT) (5) | 90,000 kg | |||||||||

| (a) Standard OIT | D3895 | minute | 100 | 100 | 100 | 100 | 100 | 100 | 100 | |

| (b) high-handed OIT | D5885 | minute | 400 | 400 | 400 | 400 | 400 | 400 | 400 | |

| 85℃ Oven aging (minimum average) (5)(6) | Per formula | |||||||||

| (A) Standard OIT is retained after 90 days | D 5721 | % | 55 | 55 | 55 | 55 | 55 | 55 | 55 | |

| (B) High voltage OIT is retained for 90 days | D 3895 D5885 | % | 80 | 80 | 80 | 80 | 80 | 80 | 80 | |

| Ultraviolet resistance (7) | Per formula | |||||||||

| (a) standard OIT | D3895 | Note (8) 50 | ||||||||

| (b) Retention of high pressure OIT after 1600 hours (9) | D5885 | % | ||||||||

Product Applications:

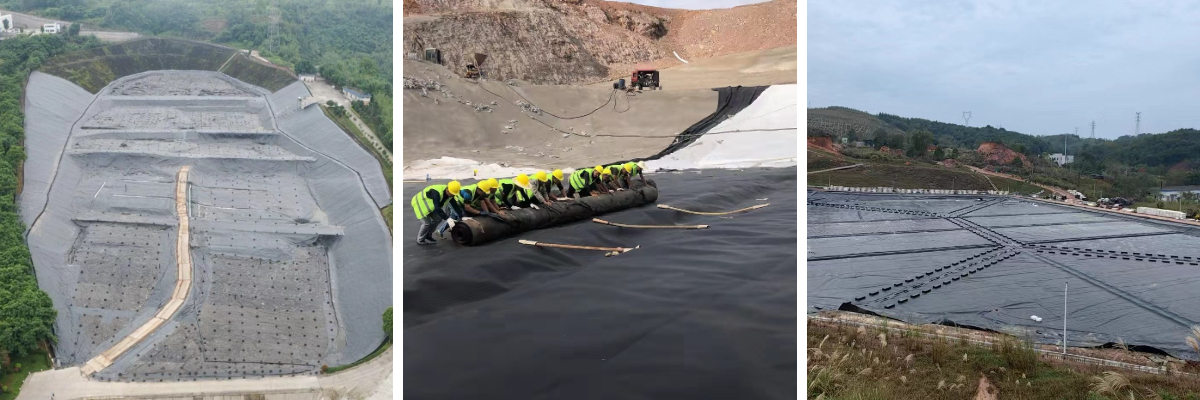

1. Water conservancy engineering: Geomembrane 500 Micron plays a crucial role as an anti-seepage layer in the construction of water conservancy facilities such as reservoirs, dams, and canals. It can effectively prevent water leakage, greatly improve the water storage capacity of water conservancy facilities, ensure their stable operation, reduce water resource waste, provide reliable guarantees for the long-term safe operation of water conservancy projects, and maintain the stability and efficiency of the entire water conservancy system.

2. Aquaculture: Used for laying aquaculture ponds such as fish ponds and shrimp ponds, Geomembrane 500 Micron can maintain the stability of the aquaculture water body, prevent water leakage, and prevent harmful substances in the soil from infiltrating the water body. To create an excellent water quality environment for fish, shrimp and other aquatic products, meet the stable conditions required for their growth, promote the healthy growth of aquatic products, and improve the yield and quality of aquaculture.

3. Sewage treatment: In facilities such as sedimentation tanks, regulating tanks, and anaerobic tanks in sewage treatment plants, Geomembrane 500 Micron, with its chemical stability, can resist various chemicals in sewage. It can serve as an effective anti-seepage material to prevent harmful substances in sewage from leaking underground, polluting soil and groundwater, ensuring the normal operation of sewage treatment facilities, safeguarding the safety of the surrounding environment, and avoiding potential harm to the ecological environment.

4. Landfill: As an anti-seepage lining for landfills, Geomembrane 500 Micron can effectively prevent leachate from seeping into the ground, preventing it from polluting soil and groundwater. Its excellent durability and tear resistance can withstand the pressure and friction during the landfill process, ensuring that the landfill maintains good environmental performance throughout long-term use and reducing the risk of pollution to the surrounding environment.

5. Landscape engineering: In landscape water projects such as artificial lakes, fountain pools, and landscape ponds, Geomembrane 500 Micron can ensure effective storage of water bodies, maintain the normal operation of water features, and create beautiful and stable water features. Its environmental characteristics make it not have a negative impact on the landscape environment, and it can perfectly integrate with natural landscapes to create a comfortable and beautiful leisure environment for people.

Geomembrane 500 Micron, as a geomembrane product mainly made of HDPE, has demonstrated enormous application value in various fields such as water conservancy engineering, aquaculture, sewage treatment, landfill sites, and landscape engineering due to its excellent waterproof performance, high durability, good tear resistance, environmentally friendly materials, and convenient installation characteristics. It not only meets the strict requirements for waterproofing, anti-seepage, and isolation in various engineering projects, but also provides strong support for the long-term stable operation, environmental protection, and cost control of the project. It is the ideal choice for material selection in many engineering projects and contributes an important force to promoting the sustainable development of various industries.