40 mil HDPE

1.Excellent Mechanical Strength: The 40mil thickness ensures outstanding tensile, tear and puncture resistance. It can resist root penetration, rodent gnawing and external impact, making it suitable for load-bearing scenarios.

2.Strong Weather and Corrosion Resistance: Containing carbon black and antioxidant stabilizers, it is resistant to acids, alkalis and ultraviolet rays, stable in hot and cold environments, and not easy to rot or mildew, suitable for outdoor and chemical scenarios.

3.Ultra-Low Permeability: The dense molecular structure combined with 40mil thickness forms an efficient barrier, with excellent anti-leakage performance, making it a core material for sealing systems.

4.Long-Term Durability: Made of virgin resin with no impurities, it has a service life of 70-100 years in underground light-proof environments. It is convenient for construction and splicing, with strong long-term stability.

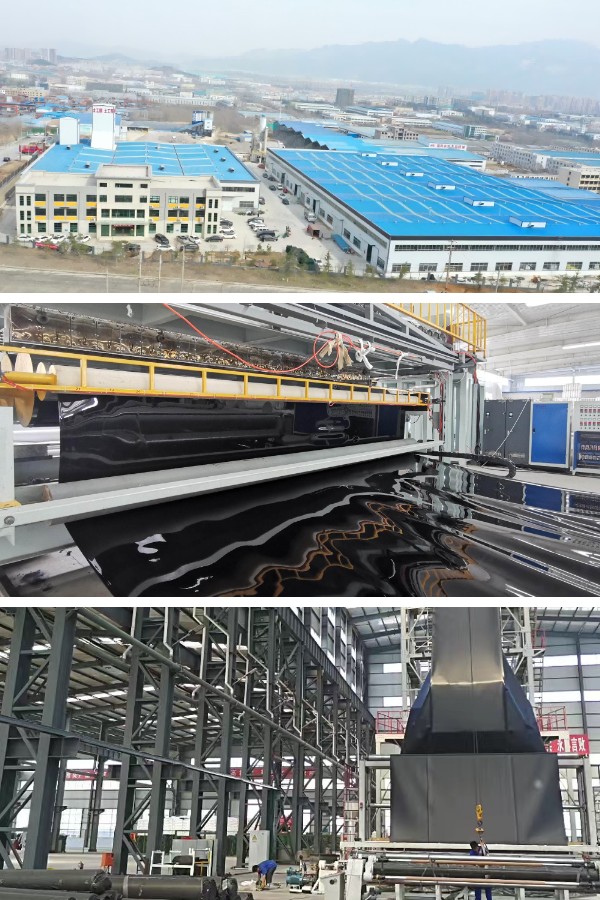

Product Introduction

I. Basic Properties

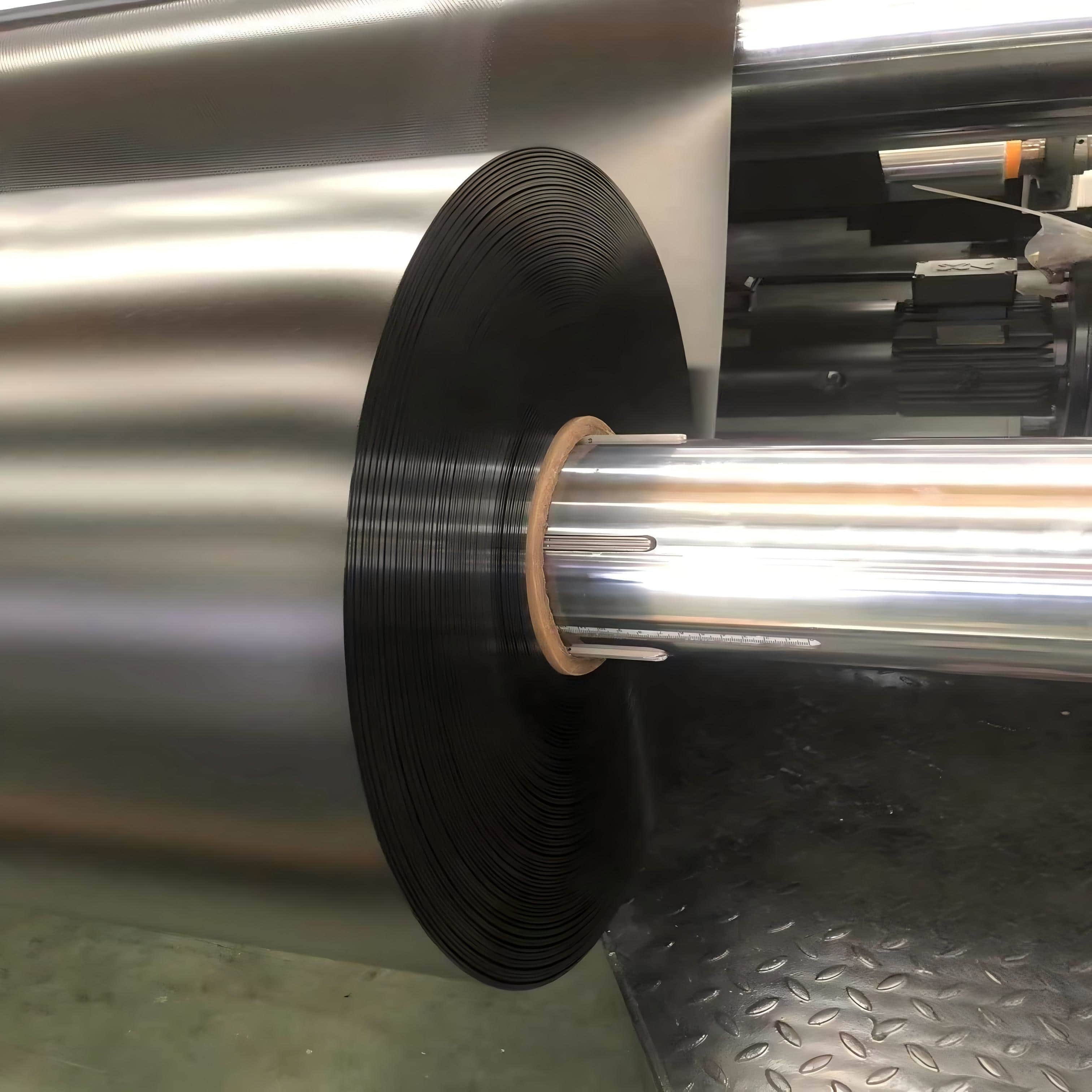

Material Foundation: 40 mil HDPE takes high-density polyethylene (HDPE) as the core raw material, processed from virgin resin with no impurities, featuring dense and regular molecular arrangement.

Specification Parameters: Thickness is 40mil (1mil ≈ 0.0254mm, 40mil ≈ 1.016mm), with stable physical structure and dimensions.

Component Characteristics: Added with carbon black and antioxidant stabilizers, which optimize the material's weather resistance and anti-aging performance, enhancing long-term use stability.

II. Core Functions

Anti-seepage and Barrier Function: Relies on dense molecular structure and 40mil thickness to form an efficient barrier layer, which can effectively prevent liquid and gas penetration and meet the needs of sealing scenarios.

Structural Bearing Function: Possesses excellent tensile, tear and puncture resistance, capable of withstanding external impact, root penetration and rodent gnawing, meeting the usage requirements of load-bearing and protection scenarios.

Environment Adaptation Function: Resistant to acid and alkali corrosion and ultraviolet radiation, maintains stable performance in alternating high and low temperature environments, and is suitable for outdoor, chemical, underground and other scenarios.

III. Main Features

Combination of High Strength and Toughness: Outstanding mechanical properties supported by thickness, while retaining the toughness of polyethylene material, not prone to brittle fracture and damage.

Long-term Durability: Combined with virgin material and stable components, it has a service life of 70-100 years in underground light-proof environments, not easy to rot, mildew or age, with low maintenance cost.

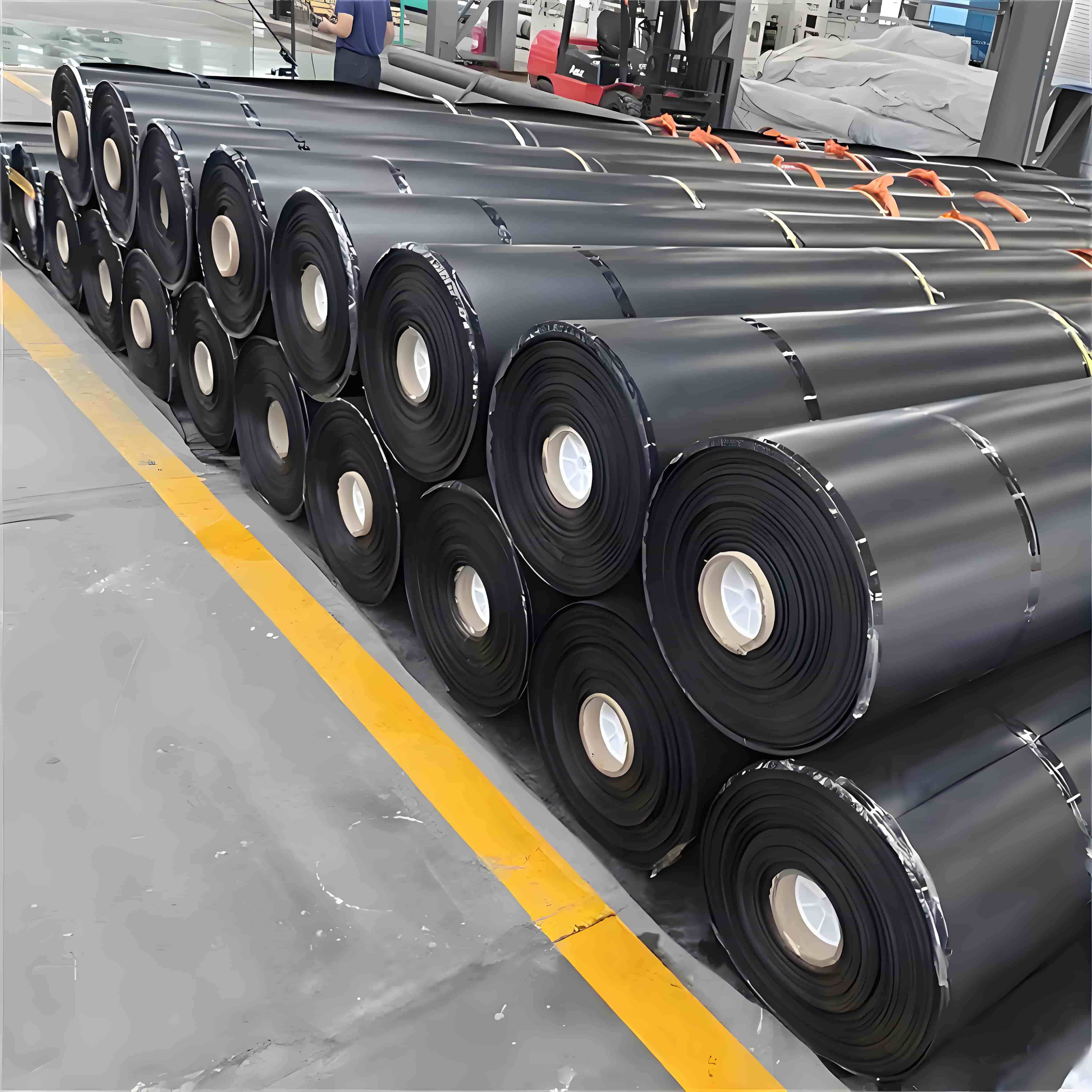

Convenient Construction: The material has good processing and splicing performance, the construction process is simple and efficient, and the splices have strong sealing performance, ensuring the overall use effect.

Product Parameters

Metric | ASTM | unit | Test value | Minimum test frequency | ||||||

test method | 0.75 mm | 1.00 mm | 1.25 mm | 1.50 mm | 2.00 mm | 2.50mm | 3.00 mm | |||

Minimum average thickness | D5199 | mm | 0.75 | 1 | 1.25 | 1.5 | 2 | 2.5 | 3 | Per volume |

Minimum value (any one of 10) | -10% | -10% | -10% | -10% | -10% | -10% | -10% | |||

minimum density | D 1505/D 792 | g/cm3 | 0.94 | 0.94 | 0.94 | 0.94 | 0.94 | 0.94 | 0.94 | 90,000 kg |

Minimum average tensile performance (1) | D638 Type IV | |||||||||

Breakage strength, | N/mm | 20 | 27 | 33 | 40 | 53 | 67 | 80 | 9,000 kg | |

yield strength | N/mm | 11 | 15 | 18 | 22 | 29 | 37 | 44 | ||

Strain extension, | % | 700 | 700 | 700 | 700 | 700 | 700 | 700 | ||

yield extension | % | 12 | 12 | 12 | 12 | 12 | 12 | 12 | ||

Minimum strength of right-angle tear | D 1004 | N | 93 | 125 | 156 | 187 | 249 | 311 | 374 | 20,000 kg |

Minimum puncture strength | D4833 | N | 240 | 320 | 400 | 480 | 640 | 800 | 960 | 20,000 kg |

Constant tensile load stress cracking (2) | D5397 | hour | 300 | 300 | 300 | 300 | 300 | 300 | 300 | Based on GRI GM-10 |

Carbon black content | D 1603(3) | % | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 9,000 kg |

Carbon black dispersion | D5596 | Note (4) | Note (4) | Note (4) | Note (4) | Note (4) | Note (4) | Note (4) | 20,000 kg | |

Oxygen induction time (OIT) (5) | 90,000 kg | |||||||||

(a) Standard OIT | D3895 | minute | 100 | 100 | 100 | 100 | 100 | 100 | 100 | |

(b) high-handed OIT | D5885 | minute | 400 | 400 | 400 | 400 | 400 | 400 | 400 | |

85℃ Oven aging (minimum average) (5)(6) | Per formula | |||||||||

(A) Standard OIT is retained after 90 days | D 5721 | % | 55 | 55 | 55 | 55 | 55 | 55 | 55 | |

(B) High voltage OIT is retained for 90 days | D 3895 D5885 | % | 80 | 80 | 80 | 80 | 80 | 80 | 80 | |

Ultraviolet resistance (7) | Per formula | |||||||||

(a) standard OIT | D3895 | Note (8) 50 | ||||||||

(b) Retention of high pressure OIT after 1600 hours (9) | D5885 | % | ||||||||

Product Application

(1) Geotechnical and Infrastructure Sector

Imperible Geomembrane: Used for bottom seepage prevention in landfills, artificial lakes, and reservoirs. A thickness of 1.016 mm effectively blocks liquid infiltration and resists acid and alkali corrosion in the soil.

Tunnel/Underground Engineering Lining: Serves as a waterproof and corrosion-resistant layer for underground structures, preventing groundwater or soil pollutants from eroding the main structure.

(2) Packaging and Transportation Sector

Heavy Cargo Packaging Film: Used for surface covering of large machinery and metal components to prevent scratches, moisture, and rust during transportation.

Chemical Drum Lining: Adhered to the inside of metal or plastic drums to isolate highly corrosive liquids (such as acid and alkali solutions) from the drum body, extending the container's service life.

(3) Building Materials and Home Furnishings Sector

Corrosion-resistant Pipe/Tank Lining: Used for the inner walls of pipes transporting chemical liquids and small storage tanks, replacing expensive stainless steel materials, reducing costs, and providing stronger corrosion resistance.

Outdoor Flooring/Boatwalk Panels: Made by extrusion molding into spliced panels for balconies and park boardwalks, resistant to sun and rain and not easily deformed.

(4) Agriculture and Horticulture

Thickened Irrigation Pipes: Used as main irrigation pipes in orchards and farmlands, with a thickness of 1.016 mm, they can withstand certain water pressure and are resistant to chemical corrosion from pesticides and fertilizers.

Greenhouse Ground Cover Film: Lay on the greenhouse floor to prevent weeds and retain moisture. It is more durable than plastic film and can be reused for 2-3 planting seasons.

Summary

40 mil (approximately 1.016 mm) high-density polyethylene (HDPE) boasts core advantages such as weather resistance, chemical corrosion resistance, and a balance between strength and processability, making it widely applicable across four major sectors: In geotechnical and infrastructure, it can serve as an impermeable geomembrane for landfills and artificial lakes, as well as a waterproof liner for tunnels, achieving liquid barrier and structural protection; in packaging and transportation, it can act as a scratch- and moisture-proof packaging film for heavy goods and a liner for chemical drums, isolating them from corrosion and damage; in building materials and home furnishings, it can be used as an anti-corrosion liner for chemical pipelines/storage tanks to reduce costs, or made into outdoor flooring and boardwalk panels to withstand sun and rain; in agriculture and horticulture, it is suitable for thickened irrigation pipes in orchards and farmlands (resistant to water pressure and chemical corrosion) and greenhouse ground covering films (weed control, moisture retention, and reusability), achieving a balance between performance and cost for adapting to various scenarios.