HDPE Concrete Liner

1. Excellent anti-seepage performance: Its permeability coefficient is extremely low, which can effectively block the penetration of liquids such as water, water vapor, oil, chemical solutions, etc., ensuring the sealing of engineering structures.

2. Strong chemical stability: It has good ability to resist acid, alkali, salt, and various oils and organic solvents corrosion

3. Durability and anti-aging property: by adding anti-aging agents such as carbon black, it can effectively resist ultraviolet radiation, slow down the aging process of materials, and has a long service life, up to decades or more.

4. Good mechanical properties: It has high tensile strength, fracture elongation, and tear resistance, can adapt to uneven settlement and certain deformation of the foundation, and is not easily broken.

Product Introduction:

1. Basic Properties

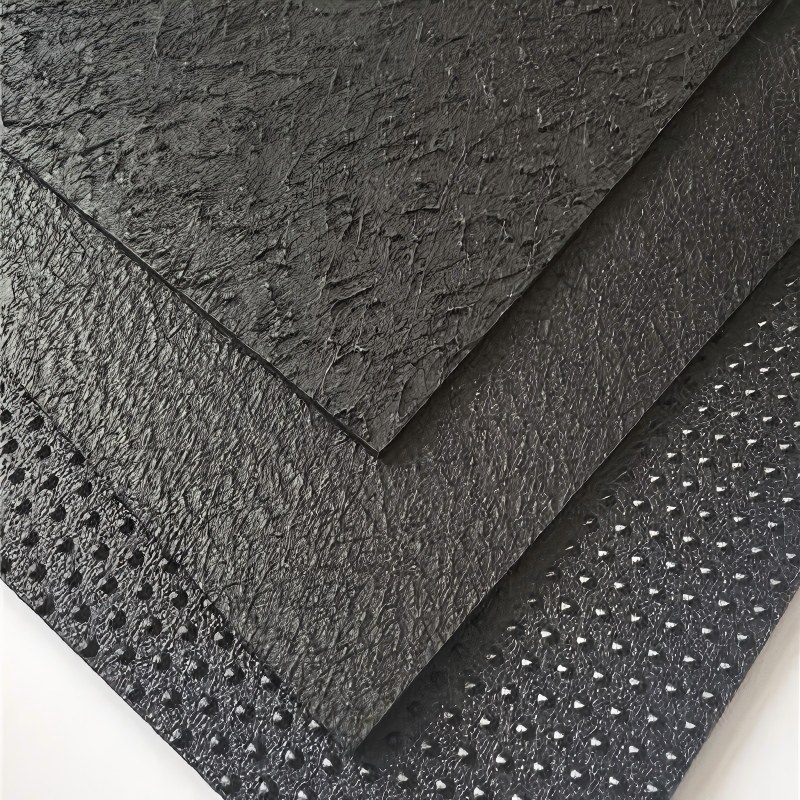

HDPE Concrete Liner is a high-performance composite geosynthetic material, made from high-density polyethylene (HDPE) resin combined with reinforced additives via extrusion molding. It features a smooth or textured surface (textured type enhances friction with concrete/soil), with customizable thickness ranging from 0.5mm to 3.0mm. It has excellent chemical stability, low temperature resistance (-60℃ to 80℃ operating temperature range), and ultra-low permeability coefficient (≤1.0×10⁻¹³ cm/s), meeting strict anti-seepage standards for engineering projects.

2. Core Functions

High-efficiency anti-seepage & impermeabilization: Acts as a barrier layer to block the penetration of water, chemical liquids, or harmful substances, preventing leakage of liquids in projects such as reservoirs, landfills, and chemical storage tanks, and avoiding soil and groundwater pollution.

Concrete structure protection: Isolates concrete from corrosive media (e.g., acid, alkali, salt solutions), reduces erosion and aging of concrete structures, and extends the service life of engineering facilities.

Enhanced structural integrity: Its good tensile strength and toughness complement concrete’s brittleness, resisting slight deformation of the base layer without cracking, and improving the overall stability of the liner system.

3. Main Characteristics

Durability & corrosion resistance: Resists erosion by acids, alkalis, salts, and organic solvents, and is UV-resistant, suitable for long-term outdoor or harsh working environments.

Easy construction & installation: Lightweight, flexible, and easy to cut and weld; can be laid on uneven surfaces, with hot-melt welding ensuring seamless joints and reliable anti-seepage effect.

Cost-effectiveness & eco-friendliness: Requires less maintenance during service, reducing long-term engineering costs; HDPE material is non-toxic, recyclable, and does not cause secondary environmental pollution.

Product Parameters:

Metric | ASTM | unit | Test value | Minimum test frequency | ||||||

test method | 0.75 mm | 1.00 mm | 1.25 mm | 1.50 mm | 2.00 mm | 2.50mm | 3.00 mm | |||

Minimum average thickness | D5199 | mm | 0.75 | 1 | 1.25 | 1.5 | 2 | 2.5 | 3 | Per volume |

Minimum value (any one of 10) | -10% | -10% | -10% | -10% | -10% | -10% | -10% | |||

minimum density | D 1505/D 792 | g/cm3 | 0.94 | 0.94 | 0.94 | 0.94 | 0.94 | 0.94 | 0.94 | 90,000 kg |

Minimum average tensile performance (1) | D638 Type IV | |||||||||

Breakage strength, | N/mm | 20 | 27 | 33 | 40 | 53 | 67 | 80 | 9,000 kg | |

yield strength | N/mm | 11 | 15 | 18 | 22 | 29 | 37 | 44 | ||

Strain extension, | % | 700 | 700 | 700 | 700 | 700 | 700 | 700 | ||

yield extension | % | 12 | 12 | 12 | 12 | 12 | 12 | 12 | ||

Minimum strength of right-angle tear | D 1004 | N | 93 | 125 | 156 | 187 | 249 | 311 | 374 | 20,000 kg |

Minimum puncture strength | D4833 | N | 240 | 320 | 400 | 480 | 640 | 800 | 960 | 20,000 kg |

Constant tensile load stress cracking (2) | D5397 | hour | 300 | 300 | 300 | 300 | 300 | 300 | 300 | Based on GRI GM-10 |

Carbon black content | D 1603(3) | % | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 9,000 kg |

Carbon black dispersion | D5596 | Note (4) | Note (4) | Note (4) | Note (4) | Note (4) | Note (4) | Note (4) | 20,000 kg | |

Oxygen induction time (OIT) (5) | 90,000 kg | |||||||||

(a) Standard OIT | D3895 | minute | 100 | 100 | 100 | 100 | 100 | 100 | 100 | |

(b) high-handed OIT | D5885 | minute | 400 | 400 | 400 | 400 | 400 | 400 | 400 | |

85℃ Oven aging (minimum average) (5)(6) | Per formula | |||||||||

(A) Standard OIT is retained after 90 days | D 5721 | % | 55 | 55 | 55 | 55 | 55 | 55 | 55 | |

(B) High voltage OIT is retained for 90 days | D 3895 D5885 | % | 80 | 80 | 80 | 80 | 80 | 80 | 80 | |

Ultraviolet resistance (7) | Per formula | |||||||||

(a) standard OIT | D3895 | Note (8) 50 | ||||||||

(b) Retention of high pressure OIT after 1600 hours (9) | D5885 | % | ||||||||

Product Applications:

I. Water Conservancy and Hydropower Projects

Anti-seepage for Reservoirs and Water Storage Tanks

Used as an anti-seepage liner for reservoir dams, laid on the upstream face or dam foundation to prevent water leakage and improve reservoir water storage efficiency. It is particularly suitable for low-cost anti-seepage renovation of small reservoirs and water storage tanks, and can be directly laid on compacted foundations, reducing the amount of concrete pouring work.

Canals and Water Diversion Projects

Laying HDPE geomembrane in irrigation canals and main water transmission canals can significantly reduce water transmission loss (leakage rate can be reduced to below 0.1%), while resisting water scouring and erosion of canal soil. Compared with concrete lining, the construction is faster and the later maintenance cost is lower.

Tailrace Canals and Water Storage Tanks of Hydropower Stations

It protects the foundation around hydropower stations from long-term water immersion, prevents structural settlement caused by soil softening, and extends the service life of the project.

II. Environmental Protection Projects

Anti-seepage Systems for Landfills

This is one of the core application fields of HDPE geomembrane. As the anti-seepage liner and leachate collection layer of landfills, it must meet strict environmental standards (such as thickness ≥ 1.5mm, puncture strength ≥ 300N). It can prevent leachate from seeping into soil and groundwater, and block the leakage of landfill gas (methane) to ensure the ecological safety of the surrounding area.

Hazardous Waste Disposal Sites

For landfills of hazardous wastes such as chemical waste and medical waste, HDPE geomembrane must have stronger chemical corrosion resistance, and a double-liner structure (two layers of HDPE membrane + intermediate leachate monitoring layer) is usually adopted to prevent the leakage of toxic and harmful substances.

Anti-seepage for Water Tanks in Sewage Treatment Plants

Used as the inner liner of structures such as regulating tanks, biochemical tanks, and sludge tanks, replacing traditional concrete anti-seepage. HDPE geomembrane is resistant to acid and alkali corrosion, can adapt to the complex chemical environment in sewage treatment tanks, and has a short construction period, enabling rapid commissioning.

III. Civil Engineering and Construction Fields

Anti-seepage for Basements and Underground Garages

As an external anti-seepage internal pasting or external anti-seepage external pasting waterproof layer for underground buildings, it is laid between the foundation and the basement wall to prevent groundwater infiltration and improve the building waterproof grade. Compared with coiled material waterproofing, it has stronger integrity and no risk of joint leakage.

Anti-seepage for Subgrades and Tunnels

In the treatment of soft soil foundations of high-grade highways, HDPE geomembrane is laid to isolate groundwater and prevent subgrade softening; in tunnel projects, it is used as an anti-seepage layer behind the lining to block mountain seepage and ensure the internal dryness of the tunnel.

Artificial Lakes and Landscape Water Pools

As the anti-seepage liner for park artificial lakes and community landscape water pools, it can be directly laid on compacted clay or sand layers, and protected with geotextiles to prevent the membrane from being punctured by sharp objects, having both anti-seepage and ecological protection functions.

IV. Mining Engineering

Anti-seepage for Tailings Ponds

Tailings ponds of metal mines and non-metal mines need to be laid with HDPE geomembrane as the anti-seepage layer to prevent heavy metal ions and harmful liquids in tailings slurry from seeping into soil and groundwater, avoiding pollution of surrounding farmland and water sources.

Anti-seepage for Heap Leaching Sites

In the heap leaching process of gold mines, copper mines, etc., HDPE geomembrane is laid in heap leaching sites to prevent the leakage of leachate (such as sodium cyanide solution), and facilitate the recovery and recycling of leachate.

V. Agriculture and Aquaculture

Water Storage Tanks and Water-saving Irrigation

HDPE geomembrane is laid in agricultural irrigation water storage tanks to reduce water storage leakage and ensure the supply of irrigation water in dry seasons; it is also widely used in the anti-seepage of water sources in drip irrigation and sprinkler irrigation systems.

Aquaculture Ponds

As the inner liner of fish ponds, shrimp ponds, and sea cucumber culture ponds, HDPE geomembrane is smooth and corrosion-resistant, which can prevent the leakage of aquaculture water, facilitate pond cleaning and disinfection, reduce the occurrence of diseases, and improve aquaculture efficiency.

With core advantages such as excellent anti-seepage performance, corrosion and wear resistance, convenient construction, and low maintenance cost, HDPE geomembrane has been widely used in many key fields including water conservancy and hydropower, environmental protection, civil engineering and construction, mining, and agriculture and aquaculture, becoming an important material to ensure project safety, ecological environmental protection, and efficient production. Its application not only solves the pain points of traditional anti-seepage technologies such as large engineering volume, easy leakage, and poor adaptability, but also can optimize the structural design according to the special needs of different scenarios (such as chemical resistance for hazardous waste disposal and erosion resistance for water conservancy projects). It plays an irreplaceable role in saving resources, protecting the ecological environment, and extending the service life of projects. In the future, with the further improvement of anti-seepage standards in various industries, its application scenarios will continue to expand, and the market demand will also grow steadily.