Non Woven Needle Punched Geotextile

1.High strength: The fibers are entangled to form a three - dimensional structure, with strong tensile, tear - resistant, and bursting - resistant capabilities.

2.Good permeability and filtration: The pores are uniform, allowing water to pass through while retaining soil particles, playing a role in filtration and drainage.

3.Excellent weather resistance: Resistant to acids, alkalis, aging, and microorganisms, adaptable to harsh environments such as humidity and salinity.

4.Convenient construction: Soft in texture and easy to cut, it can adapt to complex terrains, featuring high construction efficiency and low cost.

5.Lightweight: It is convenient for transportation and handling, reducing logistics costs.

6.Versatility: It can be compounded with other materials, having multiple functions such as reinforcement, seepage prevention, and drainage.

7.Environmentally friendly economy: Some can use recycled materials, are easy to degrade after being discarded, and have a low comprehensive cost.

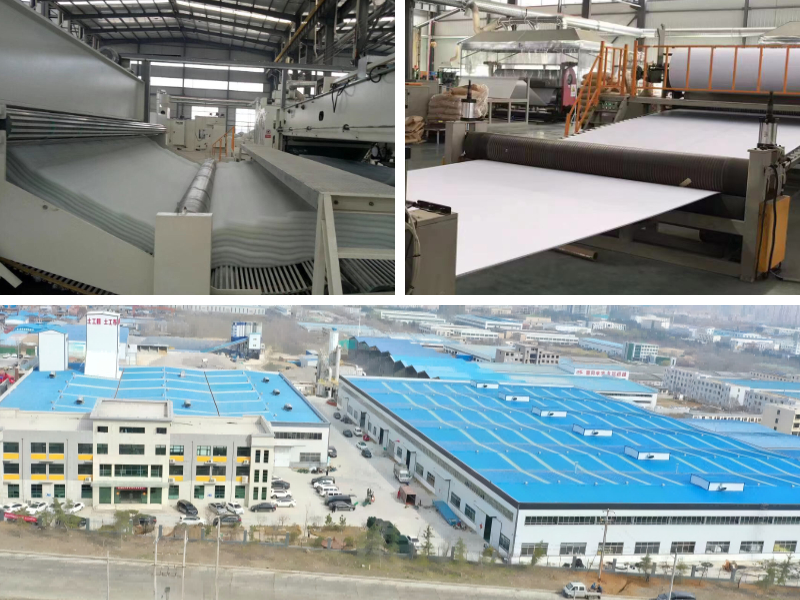

Product Introduction:

Non Woven Needle Punched Geotextile is a kind of geosynthetic material made by the needle - punching process. Using synthetic fibers (such as polypropylene PP, polyester PET, etc.) as raw materials, after carding into a web, the barbed needles of the needle-punching machine repeatedly penetrate, causing the fibers to entangle with each other, forming a three-dimensional structural material with certain strength and thickness, which has functions such as reinforcement, filtration, drainage, isolation, and anti-seepage.It belongs to one type of non - woven fabric (non - woven cloth) and is mainly used in fields such as civil engineering and environmental governance.

Structural and Performance Characteristics

Three - dimensional Porous Structure: The fibers entangle to form irregular pores, which have both water permeability and filtering properties (allowing water to pass through while blocking soil particles).

Outstanding Mechanical Properties: High tensile strength and tear strength, capable of resisting the tensile force generated by soil deformation, suitable for reinforcement scenarios.

Product Parameters:

project | metric | ||||||||||

| Nominal strength/(kN/m) | |||||||||||

| 6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |||

| 1 | Longitudinal and transverse tensile strength / (kN/m) ≥ | 6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |

| 2 | Maximum elongation at maximum load in longitudinal and transverse directions/% | 30~80 | |||||||||

| 3 | CBR top penetration strength /kN ≥ | 0.9 | 1.6 | 1.9 | 2.9 | 3.9 | 5.3 | 6.4 | 7.9 | 8.5 | |

| 4 | Longitudinal and transverse tearing strength /kN | 0.15 | 0.22 | 0.29 | 0.43 | 0.57 | 0.71 | 0.83 | 1.1 | 1.25 | |

| 5 | Equivalent aperture O.90(O95)/mm | 0.05~0.30 | |||||||||

| 6 | Vertical permeability coefficient/(cm/s) | K× (10-¹~10-), where K=1.0~9.9 | |||||||||

| 7 | Width deviation rate /% ≥ | -0.5 | |||||||||

| 8 | Unit area mass deviation rate /% ≥ | -5 | |||||||||

| 9 | Thickness deviation rate /% ≥ | -10 | |||||||||

| 10 | Thickness coefficient of variation (CV)/% ≤ | 10 | |||||||||

| 11 | Dynamic perforation | Puncture hole diameter/mm ≤ | 37 | 33 | 27 | 20 | 17 | 14 | 11 | 9 | 7 |

| 12 | Longitudinal and transverse fracture strength (grab method)/kN ≥ | 0.3 | 0.5 | 0.7 | 1.1 | 1.4 | 1.9 | 2.4 | 3 | 3.5 | |

| 13 | Ultraviolet resistance (Xenon arc lamp method) | Longitudinal and transverse strength retention rate% ≥ | 70 | ||||||||

| 14 | Ultraviolet resistance (fluorescence UV lamp method) | Longitudinal and transverse strength retention rate% ≥ | 80 | ||||||||

Product Applications:

1.Civil Engineering Field

Highway and Railway Construction

Subgrade Reinforcement: Laid between the subgrade and the base course, it enhances the tensile strength of the soil, preventing road surface settlement and cracks (such as soft soil foundation reinforcement).

Separation and Filtration: It separates soil layers of different particle sizes to avoid mixing; meanwhile, it filters groundwater to prevent sediment from clogging the drainage system.

Slope Protection: It covers the slope surface, fixes the soil, and prevents landslides caused by rainwater erosion. It is often used in combination with vegetation greening.

Water Conservancy Projects

Dams and Rivers: Used for reinforcement under the anti-seepage layer of dams to improve the dam's deformation resistance; filter and drain in river bank protection to maintain soil and water stability.

Reservoirs and Channels: Laid around reservoirs to filter seepage water and prevent soil erosion; used as an isolation layer at the bottom or on both sides of channels to reduce seepage loss.

2.Field of Environmental Engineering

Landfill

Laid above the impermeable membrane (HDPE membrane) to protect the membrane from being punctured by gravel and sharp objects, and at the same time filter the leachate to prevent blockage of the drainage system.

When the landfill is closed, it serves as a component of the cover layer to assist vegetation growth, control dust and rainwater infiltration.

Sewage Treatment and Mine Restoration

Sewage Treatment Plant: It is used for sludge dewatering and filtration to separate water from solid particles; or it serves as the cushion material of the aeration tank to protect the bottom equipment of the tank.

Mine Ecological Restoration: It covers the slopes of mine pits or abandoned sites, reinforces the soil, provides a basis for vegetation restoration, and at the same time prevents the spread of heavy metal pollution.

3.Agriculture and Ecological Engineering

Farmland and Soil and Water Conservation

Farmland Improvement: Laid at the bottom of the farmland to improve soil permeability, prevent salinization; or reinforce the edges of terraced fields to reduce soil erosion.

Greenhouse: As the drainage layer at the bottom of the greenhouse to prevent waterlogging from affecting the roots of crops, and at the same time separate the soil from the plastic film to extend the service life of the plastic film.

Ecological Greening

Slope Greening: Used in combination with grass seeds and nutrient soil to fix the soil and provide growth space for plant roots. It is often used for the ecological restoration of highway and railway slopes.

Constructed Wetland: As the supporting layer of wetland fillers, it filters impurities in sewage, provides a carrier for microbial attachment, and enhances the purification effect.

4.Other Application Scenarios

Airport and Port Engineering: Reinforce the foundation of airport runways to improve bearing capacity; prevent seepage and reinforce the revetments of port terminals to resist the impact of ocean waves.

Construction Engineering: Isolate and drain the damp-proof layer of basements, and use as the drainage and filtration layer for roof greening to reduce the damage of water accumulation to the building structure.

Military and Emergency Engineering: Laying temporary roads, rapidly constructing flood control dikes, and quickly responding to engineering needs by leveraging its portability and ease of construction.

Non Woven Needle Punched Geotextile is a functional geotechnical material made through the mechanical entanglement (needle - punching) process. Relying on its three - dimensional structure and the characteristics of synthetic fibers, it realizes core functions such as "reinforcement, filtration, and drainage" in civil engineering, and is a commonly used material in modern environmentally friendly projects.