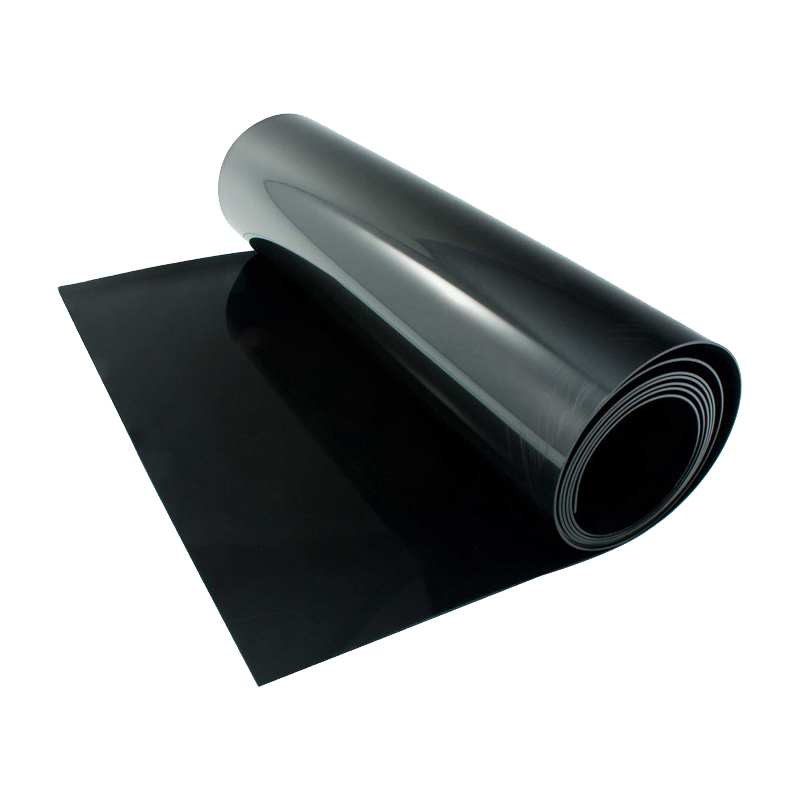

2mm HDPE Liner

1. High cost-effectiveness: Compared with traditional anti-seepage materials, geomembrane materials have lower costs, shorter construction periods, and more comprehensive cost advantages.

2. Adapt to complex terrain: Good flexibility, able to fit irregular substrates, solving the problem of traditional rigid materials being difficult to cover.

3. Good environmental friendliness: Using non-toxic polymer materials, it has no pollution to soil and water, and meets the requirements of environmental engineering.

4. Multifunctionality: In addition to anti-seepage, it can also have functions such as isolation, reinforcement, and filtration, simplifying engineering design.

Product Introduction:

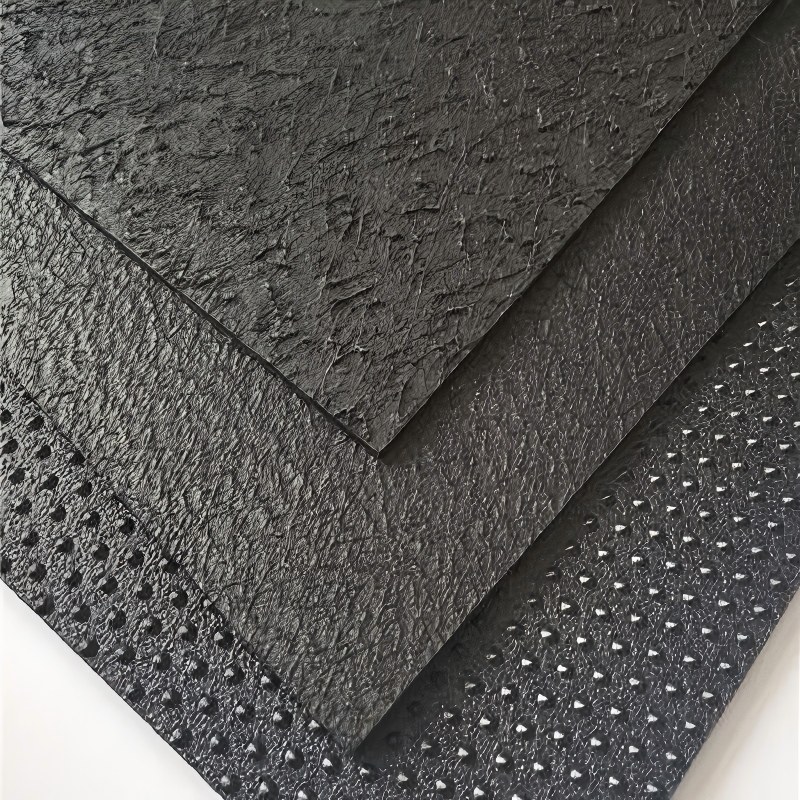

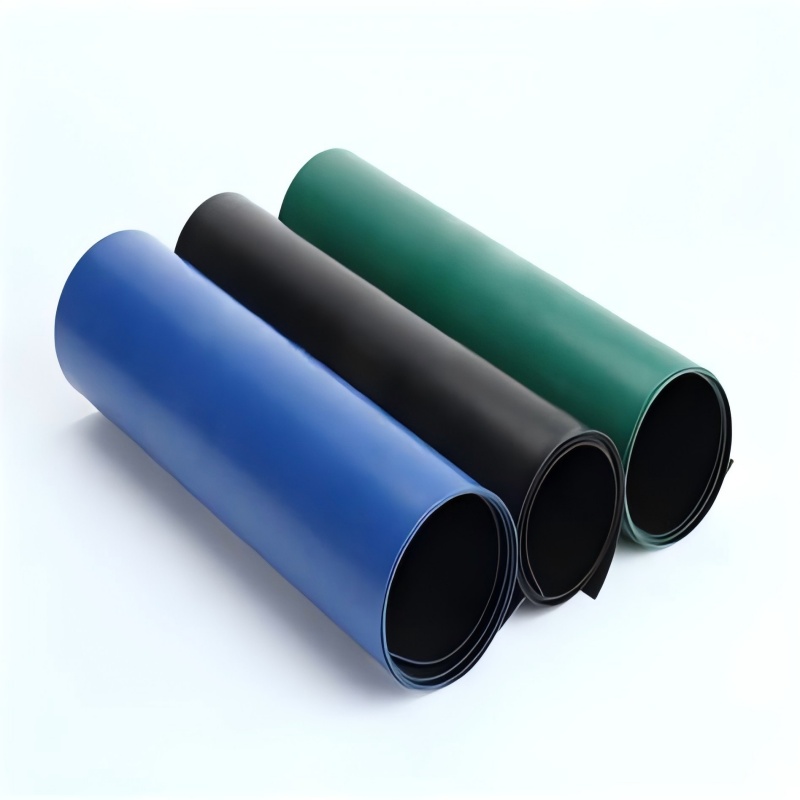

2mm HDPE Liner is a waterproof and barrier material made from polymer materials, commonly used in fields such as geotechnical engineering and hydraulic engineering, to prevent seepage, isolate, and reinforce structures. It is processed through pressing, blow molding and other processes, and its shape is mostly in the form of a thin film, with good chemical stability and mechanical properties.

characteristic

1. Excellent anti-seepage performance: The molecular structure is dense, which can effectively prevent liquid infiltration and has a significant barrier effect on media such as water, acid, and alkali.

2. High mechanical strength: It has good tensile strength, tear strength, and puncture resistance, and can adapt to the deformation and external impact of the base layer.

3. Strong environmental resistance: able to resist UV radiation, high and low temperature changes, microbial erosion, and chemical corrosion.

4. Convenient construction: The material is lightweight (usually 0.2mm-3mm thick, light weight), and can be cut and spliced according to engineering needs. It can be connected by hot melt welding or adhesive, with high efficiency.

5. Good durability: With reasonable use and maintenance, the service life is long, and some special formula products may even be longer.

Product Parameters:

Metric | ASTM | unit | Test value | Minimum test frequency | ||||||

test method | 0.75 mm | 1.00 mm | 1.25 mm | 1.50 mm | 2.00 mm | 2.50mm | 3.00 mm | |||

Minimum average thickness | D5199 | mm | 0.75 | 1 | 1.25 | 1.5 | 2 | 2.5 | 3 | Per volume |

Minimum value (any one of 10) | -10% | -10% | -10% | -10% | -10% | -10% | -10% | |||

minimum density | D 1505/D 792 | g/cm3 | 0.94 | 0.94 | 0.94 | 0.94 | 0.94 | 0.94 | 0.94 | 90,000 kg |

Minimum average tensile performance (1) | D638 Type IV | |||||||||

Breakage strength, | N/mm | 20 | 27 | 33 | 40 | 53 | 67 | 80 | 9,000 kg | |

yield strength | N/mm | 11 | 15 | 18 | 22 | 29 | 37 | 44 | ||

Strain extension, | % | 700 | 700 | 700 | 700 | 700 | 700 | 700 | ||

yield extension | % | 12 | 12 | 12 | 12 | 12 | 12 | 12 | ||

Minimum strength of right-angle tear | D 1004 | N | 93 | 125 | 156 | 187 | 249 | 311 | 374 | 20,000 kg |

Minimum puncture strength | D4833 | N | 240 | 320 | 400 | 480 | 640 | 800 | 960 | 20,000 kg |

Constant tensile load stress cracking (2) | D5397 | hour | 300 | 300 | 300 | 300 | 300 | 300 | 300 | Based on GRI GM-10 |

Carbon black content | D 1603(3) | % | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 9,000 kg |

Carbon black dispersion | D5596 | Note (4) | Note (4) | Note (4) | Note (4) | Note (4) | Note (4) | Note (4) | 20,000 kg | |

Oxygen induction time (OIT) (5) | 90,000 kg | |||||||||

(a) Standard OIT | D3895 | minute | 100 | 100 | 100 | 100 | 100 | 100 | 100 | |

(b) high-handed OIT | D5885 | minute | 400 | 400 | 400 | 400 | 400 | 400 | 400 | |

85℃ Oven aging (minimum average) (5)(6) | Per formula | |||||||||

(A) Standard OIT is retained after 90 days | D 5721 | % | 55 | 55 | 55 | 55 | 55 | 55 | 55 | |

(B) High voltage OIT is retained for 90 days | D 3895 D5885 | % | 80 | 80 | 80 | 80 | 80 | 80 | 80 | |

Ultraviolet resistance (7) | Per formula | |||||||||

(a) standard OIT | D3895 | Note (8) 50 | ||||||||

(b) Retention of high pressure OIT after 1600 hours (9) | D5885 | % | ||||||||

Product Applications:

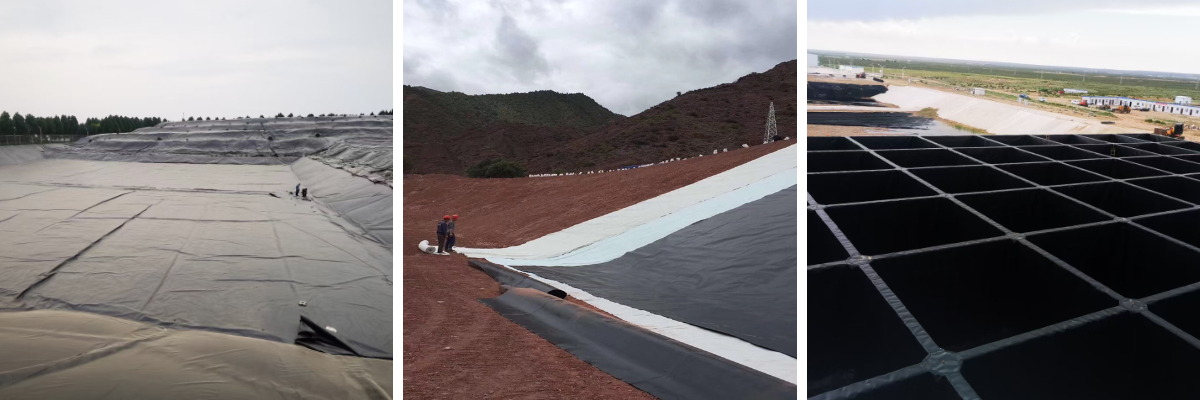

1. Water conservancy engineering

Reservoir and reservoir anti-seepage: Laying geomembranes on the dam body, bottom, and inner walls of the reservoir can effectively prevent water from seeping into the dam body or underground, improve water resource utilization, and avoid dangerous situations such as piping and landslides caused by seepage in the dam body.

Channel anti-seepage: Traditional soil channels suffer from severe leakage losses during water transportation. By laying geomembranes on the slopes and bottom of the channels, the amount of leakage can be significantly reduced (by more than 50%), improving water transmission efficiency, especially for irrigation channels in arid and water scarce areas.

Embankment anti-seepage reinforcement: For earth rock dams, embankments, etc., geomembranes can be laid on the upstream surface of the dam as anti-seepage inclined walls, or anti-seepage core walls can be set inside the dam to prevent seepage deformation and enhance the anti-seepage stability of the dam.

2. Environmental engineering

Landfill site: This is an important application scenario for geomembranes. Laying multiple layers of geomembranes (usually combined with compacted clay, geotextiles, etc. to form a composite anti-seepage system) at the bottom and periphery of a landfill can prevent leachate from seeping into groundwater bodies and prevent groundwater from entering the landfill. In addition, geomembranes are also used when capping landfills to reduce rainwater infiltration and gas release.

Sewage treatment plant: In the tank structure of sewage treatment tanks, oxidation ponds and other facilities, geomembranes can be used as anti-seepage layers to prevent sewage leakage and pollution of surrounding soil and groundwater, especially suitable for large outdoor sewage treatment facilities.

Hazardous waste disposal site: For hazardous waste containing heavy metals and toxic chemicals, high specification geomembranes (such as high-density polyethylene (HDPE) geomembranes) should be used for strict isolation to prevent the leakage of harmful substances and environmental pollution.

3. Municipal engineering

Artificial lakes, landscape water pools: Artificial lakes, park landscape water pools, etc. in cities can achieve water seepage prevention by laying geomembranes, avoiding the drying up of water pools or settlement of surrounding foundations due to seepage, and reducing the cost of later water replenishment.

Underground pipe gallery anti-seepage: The interior of the underground comprehensive pipe gallery needs to maintain a dry environment. Geomembranes should be laid on the outside or bottom of the pipe gallery structure to prevent groundwater from seeping into the gallery and protect internal pipeline equipment.

Septic tanks, biogas digesters: Small scale septic tanks, rural biogas digesters and other facilities use the anti-seepage properties of geomembranes to prevent leakage of manure and biogas, ensuring the normal operation of the facilities and avoiding pollution of the surrounding environment.

4. Transportation Engineering

Highway and railway subgrade reinforcement: When constructing highways or railways on soft soil foundations, laying geomembranes can isolate the roadbed fill from the soft soil foundation, prevent the two from mixing, and use the tensile strength of geomembranes to disperse loads, reduce foundation settlement and uneven deformation, and improve roadbed stability.

Tunnel anti-seepage: During tunnel construction, a geotextile membrane (often referred to as a "waterproof board") is laid between the initial support and the secondary lining to prevent groundwater from seeping into the interior of the tunnel, ensuring safe tunnel operation, especially suitable for tunnel projects in water rich formations.

Slope protection: Laying geomembranes (usually combined with vegetation) on highway and railway slopes can prevent rainwater from washing away the slope soil, reduce soil erosion, enhance the overall stability of the slope, and prevent landslides, collapses, and other diseases.

5. Mining Engineering

Tailings pond anti-seepage: For tailings ponds of metal mines, coal mines, etc. (storing waste slag, wastewater, etc. after beneficiation), geomembranes need to be laid at the bottom of the pond and the dam body to prevent heavy metals, acidic substances, etc. in the tailings water from infiltrating underground and polluting the soil and water sources.

Stacking yard isolation: Laying geomembranes at the bottom of the mine raw material yard and waste residue yard can isolate materials from the ground, avoid soil pollution caused by materials, and prevent the spread of sewage formed by rainwater washing materials.

6. Agriculture and Aquaculture

Agricultural irrigation water storage: In addition to channel anti-seepage, geomembranes can achieve efficient anti-seepage in water storage facilities for agricultural greenhouses and water-saving irrigation, ensuring the supply of irrigation water.

Aquaculture pond: Laying geomembranes at the bottom of fish ponds, shrimp ponds, and other aquaculture ponds can prevent water leakage and reduce the pollution of water quality caused by soil at the bottom of the pond, facilitating pond cleaning and management while avoiding the escape of aquaculture organisms.

Geomembrane has become an indispensable anti-seepage material in modern engineering, and its application scope is still expanding, especially playing an important role in environmental protection and sustainable development.