HDPE Smooth Geomembrane

1. Excellent anti-seepage performance: HDPE smooth geomembrane has an extremely low permeability coefficient, which can prevent soil and groundwater pollution caused by leachate in landfills; In the anti-seepage of reservoirs and channels in hydraulic engineering, the utilization rate of water resources can be improved.

2. High strength and toughness: It has excellent tensile strength and puncture resistance, can withstand large tensile forces without breaking, and can also resist sharp object punctures, ensuring the integrity and safety of the project.

3. Excellent weather resistance and chemical resistance: It has extremely strong resistance to ultraviolet rays, high and low temperatures and various chemicals, excellent anti-aging performance, and can be exposed for a long time with stable performance.

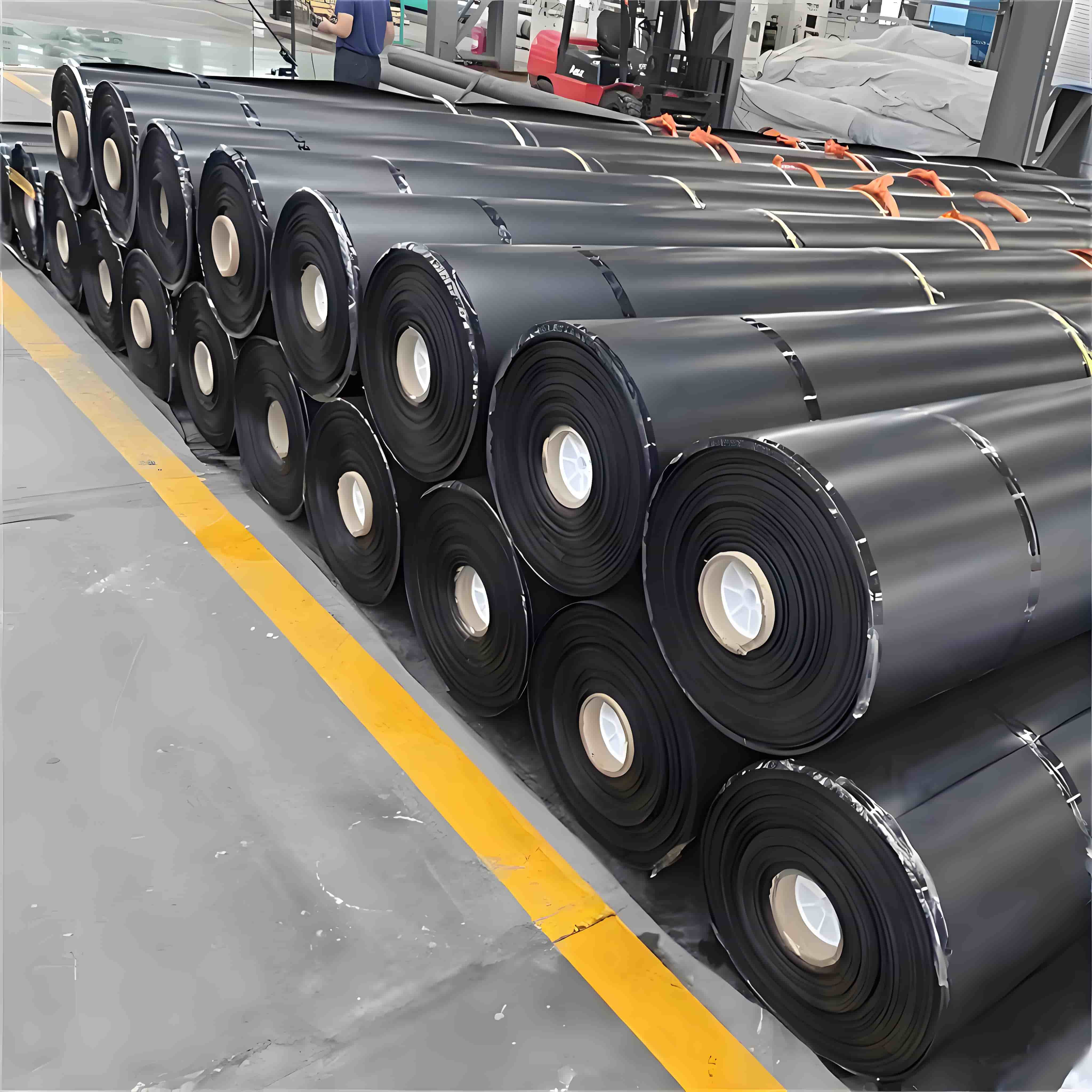

4. Convenient and efficient construction: The product is lightweight, easy to handle and lay, and can be cut and welded according to project requirements during construction, making the operation convenient and fast.

Products Introduction:

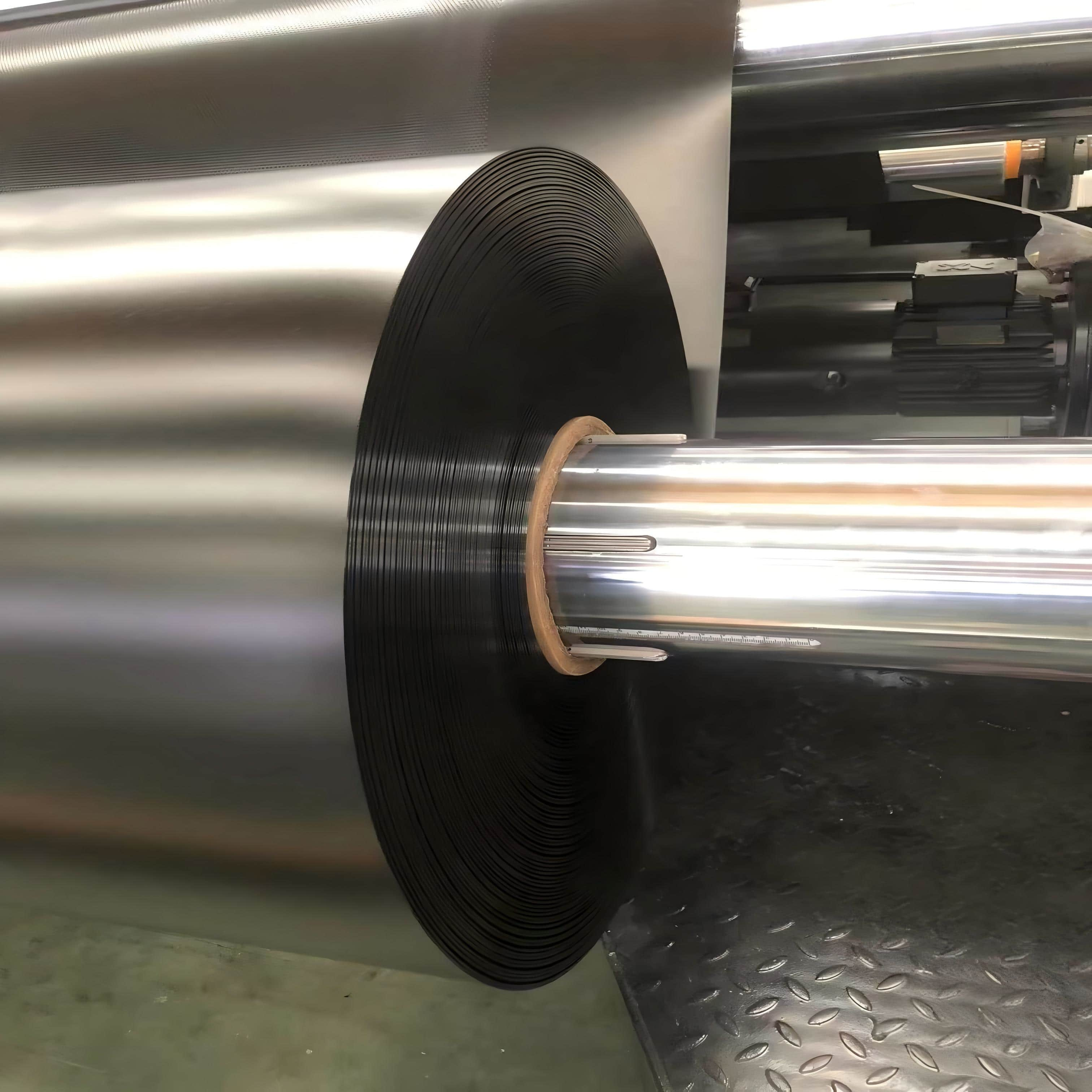

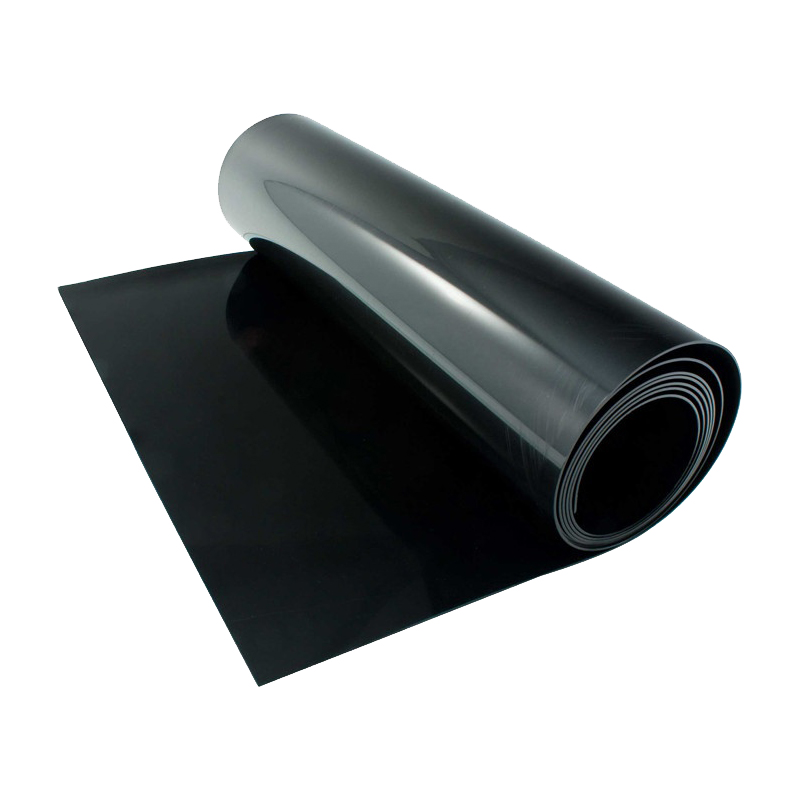

HDPE smooth geomembrane, also known as high-density polyethylene smooth geomembrane, is made of high-quality polymer - high-density polyethylene (HDPE) as the raw material. These raw materials usually come from high-grade polyethylene resins produced by large petrochemical enterprises at home and abroad. In terms of production technology, three layer coextrusion extrusion blow molding, three layer calendering molding technology or double-layer calendering rolling technology and other advanced processes are often used to mix HDPE resin with appropriate carbon black, antioxidant, anti-aging agent and UV resistant ingredients to produce geomembrane products with extremely low permeability coefficient. The film surface is smooth and flat, with a thickness specification generally between 0.2mm and 3.0mm. The common width is 2m-9m, and the length can be customized according to customer needs.

Product Features:

1. Excellent anti-seepage performance: HDPE smooth geomembrane has an extremely low permeability coefficient, which can effectively prevent liquid leakage. The high-density polyethylene native resin used is made by a special process with high molecular density, making it difficult for liquids to penetrate and effectively preventing water infiltration. Whether it is the rise of groundwater or the infiltration of surface water, it can be well blocked, providing reliable anti-seepage protection for the project.

2. High strength and toughness: It has excellent tensile strength and puncture resistance, can withstand large tensile forces without breaking, and can resist sharp object punctures. In complex geological environments, such as the presence of sharp objects such as rocks or tensile stress caused by geological subsidence, stability can still be maintained to ensure the integrity and safety of the project.

3. Strong weather resistance and chemical resistance: It has extremely strong resistance to ultraviolet radiation, high and low temperatures, and various chemical substances. It can work normally at a wide ambient temperature from -70 ℃ to 110 ℃, and can resist the corrosion of strong acids, strong alkalis, oils and other chemicals. It has excellent anti-aging performance, and can be exposed for a long time with stable performance.

4. Good physical and mechanical properties: It has high tear strength and can maintain structural integrity when torn by external forces; Strong adaptability to deformation, able to effectively overcome uneven settlement of the base surface, and can adapt to deformation requirements under different geological conditions.

5. Environmentally friendly and non-toxic: The materials used in production are all non-toxic and environmentally friendly. The anti-seepage principle is based on ordinary physical changes, and no harmful substances are produced during use, which meets environmental requirements and is an ideal choice for environmental protection, aquaculture and other projects.

6. Convenient and efficient construction: The product is lightweight and easy to handle and lay. During construction, cutting and welding can be carried out according to project requirements, with convenient and fast operation, reliable welding quality, and the ability to form a continuous and tight waterproof layer, greatly improving project quality and efficiency, while shortening the construction period, saving time and labor costs.

Product Parameters:

Metric | ASTM | unit | Test value | Minimum test frequency | ||||||

test method | 0.75 mm | 1.00 mm | 1.25 mm | 1.50 mm | 2.00 mm | 2.50mm | 3.00 mm | |||

Minimum average thickness | D5199 | mm | 0.75 | 1 | 1.25 | 1.5 | 2 | 2.5 | 3 | Per volume |

Minimum value (any one of 10) | -10% | -10% | -10% | -10% | -10% | -10% | -10% | |||

minimum density | D 1505/D 792 | g/cm3 | 0.94 | 0.94 | 0.94 | 0.94 | 0.94 | 0.94 | 0.94 | 90,000 kg |

Minimum average tensile performance (1) | D638 Type IV | |||||||||

Breakage strength, | N/mm | 20 | 27 | 33 | 40 | 53 | 67 | 80 | 9,000 kg | |

yield strength | N/mm | 11 | 15 | 18 | 22 | 29 | 37 | 44 | ||

Strain extension, | % | 700 | 700 | 700 | 700 | 700 | 700 | 700 | ||

yield extension | % | 12 | 12 | 12 | 12 | 12 | 12 | 12 | ||

Minimum strength of right-angle tear | D 1004 | N | 93 | 125 | 156 | 187 | 249 | 311 | 374 | 20,000 kg |

Minimum puncture strength | D4833 | N | 240 | 320 | 400 | 480 | 640 | 800 | 960 | 20,000 kg |

Constant tensile load stress cracking (2) | D5397 | hour | 300 | 300 | 300 | 300 | 300 | 300 | 300 | Based on GRI GM-10 |

Carbon black content | D 1603(3) | % | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 9,000 kg |

Carbon black dispersion | D5596 | Note (4) | Note (4) | Note (4) | Note (4) | Note (4) | Note (4) | Note (4) | 20,000 kg | |

Oxygen induction time (OIT) (5) | 90,000 kg | |||||||||

(a) Standard OIT | D3895 | minute | 100 | 100 | 100 | 100 | 100 | 100 | 100 | |

(b) high-handed OIT | D5885 | minute | 400 | 400 | 400 | 400 | 400 | 400 | 400 | |

85℃ Oven aging (minimum average) (5)(6) | Per formula | |||||||||

(A) Standard OIT is retained after 90 days | D 5721 | % | 55 | 55 | 55 | 55 | 55 | 55 | 55 | |

(B) High voltage OIT is retained for 90 days | D 3895 D5885 | % | 80 | 80 | 80 | 80 | 80 | 80 | 80 | |

Ultraviolet resistance (7) | Per formula | |||||||||

(a) standard OIT | D3895 | Note (8) 50 | ||||||||

(b) Retention of high pressure OIT after 1600 hours (9) | D5885 | % | ||||||||

Product Applications:

1. In the field of environmental protection and sanitation: used for bottom anti-seepage and sealing cover in domestic waste landfills, effectively preventing soil and groundwater pollution caused by leachate leakage; As an anti-seepage lining in facilities such as regulating tanks and sedimentation tanks in sewage treatment plants, to ensure that sewage does not leak; In industrial and hospital solid waste disposal sites, it can also play a good role in anti-seepage and isolation.

2. In the field of water conservancy engineering: widely used in anti-seepage, plugging and reinforcement projects for rivers, lakes, reservoir dams and riverbanks; In channel anti-seepage, it can reduce the leakage loss of water resources during transportation and improve the utilization rate of water resources; It can also be used for vertical anti-seepage core walls, slope anti-seepage and other parts of hydraulic engineering.

3. In the field of municipal engineering: used for waterproofing and anti-seepage in subway and underground construction projects; As an anti-seepage layer in planting roofs and rooftop gardens, it prevents water leakage from causing damage to the building structure; In the lining of sewage pipelines, it plays a role in preventing leakage and corrosion.

4. In the field of landscape architecture, it is widely used in the bottom lining and slope anti-seepage of artificial lakes, rivers, and reservoirs; In the bottom lining and slope protection of golf course pools, it can effectively maintain water bodies; In the waterproofing and anti-seepage of green lawns, it can ensure suitable soil moisture and provide good conditions for plant growth.

5. In the field of petrochemicals: prevent oil leakage and pollution of soil and groundwater in the anti-seepage of oil tanks in chemical plants, refineries, and gas stations; In the lining of chemical reaction tanks and sedimentation tanks, it resists the corrosion of chemical substances and ensures the safe operation of facilities.

6. Mining field: used for bottom lining and anti-seepage of washing tanks, heap leaching tanks, ash yards, dissolution tanks, material yards, and tailings ponds, to prevent harmful substances in slag from leaking and causing pollution to the surrounding environment.

7. In the field of transportation facilities, it can be used for the reinforcement and anti-seepage of road foundations. In subway and culvert engineering, it can prevent groundwater leakage from affecting the structure and improve the stability and durability of the project.

8. In the field of agriculture, it plays a role in preventing seepage, reducing water waste, improving irrigation efficiency, and ensuring water supply for agricultural production in ditches, channels, reservoirs, drinking water tanks, ponds, and irrigation systems.

9. In the field of aquaculture, it is applied in the lining of intensive and factory aquaculture ponds, fish ponds, and shrimp ponds to prevent water leakage and the infiltration of harmful substances from the soil into the water, providing a good water environment for aquaculture; It can also play an important role in the slope protection of sea cucumber circles.

HDPE smooth geomembrane, with its high-quality raw materials and advanced production technology, has excellent anti-seepage performance, high strength, good weather resistance and chemical resistance, convenient construction performance, and environmental protection and non toxicity. It plays a crucial role in a wide range of fields such as environmental sanitation, water conservancy, municipal engineering, landscaping, petrochemicals, mining, transportation facilities, agriculture, and aquaculture. It can not only effectively solve problems such as anti-seepage and isolation in engineering, ensure the safe and stable operation of the project, but also reduce project costs, improve resource utilization, and meet the demand for efficient, environmentally friendly, and durable materials in modern engineering construction. It is a highly valuable geosynthetic material.