Prefabricated Geomembrane

1. Excellent anti-seepage performance: The geomembrane material is dense and has good integrity, which can effectively block liquid infiltration. It is suitable for engineering scenarios such as water conservancy and municipal engineering that require strict anti-seepage, reducing leakage losses and environmental risks.

2. Strong weather resistance: able to resist UV radiation, high and low temperature changes, and chemical erosion such as acidity and alkalinity, maintaining stable performance in different climates and soil environments, and extending the service life of the project.

3. Convenient and efficient construction: The material is lightweight, flexible, easy to cut, splice, and lay, can adapt to complex terrain, and has a short construction period, which can reduce project costs and labor intensity.

4. Outstanding economy: Compared with traditional anti-seepage materials, the unit price of geomembrane is reasonable, and due to its fast construction, long service life, and less maintenance, the comprehensive cost is lower, which can provide a cost-effective anti-seepage solution for the project.

Products Introduction:

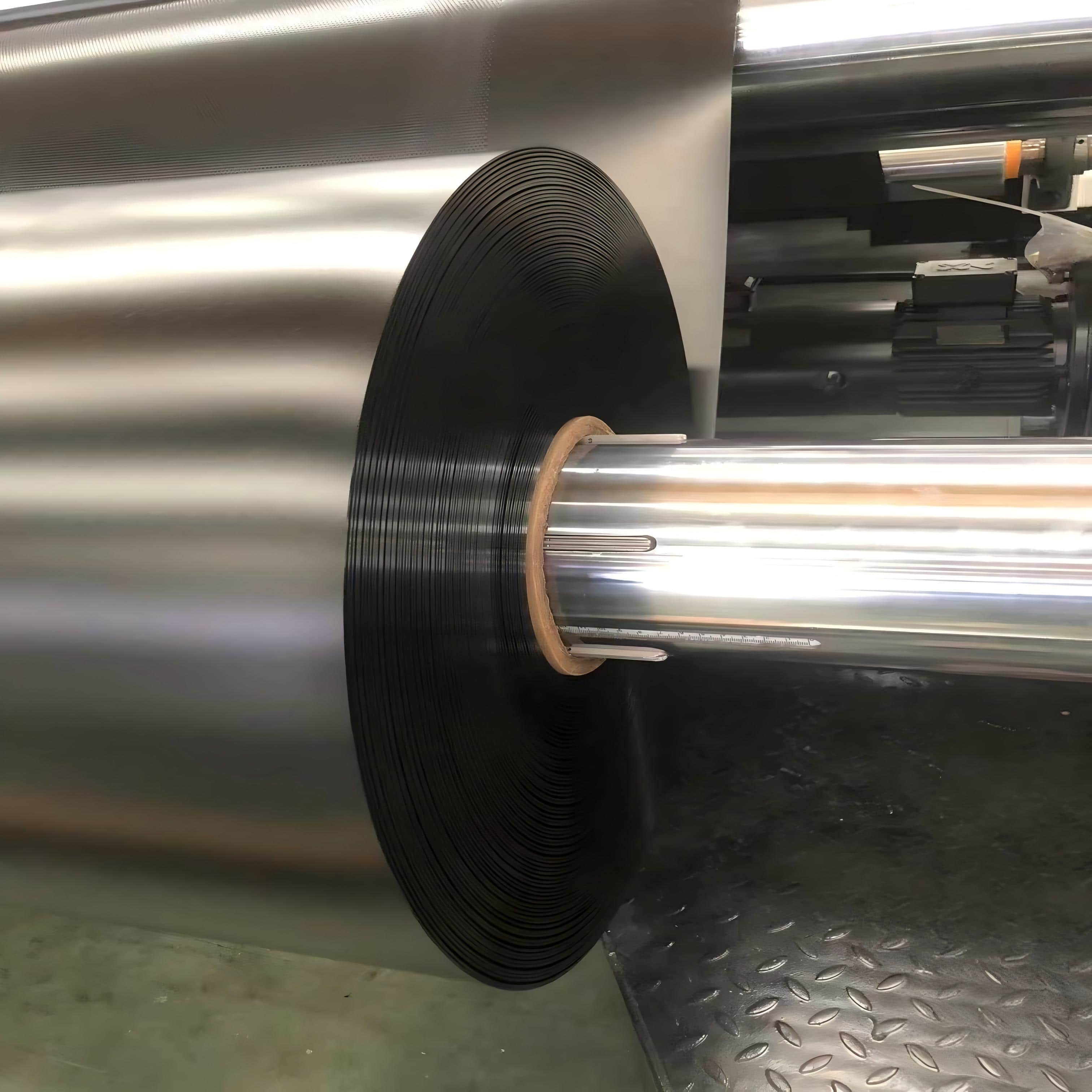

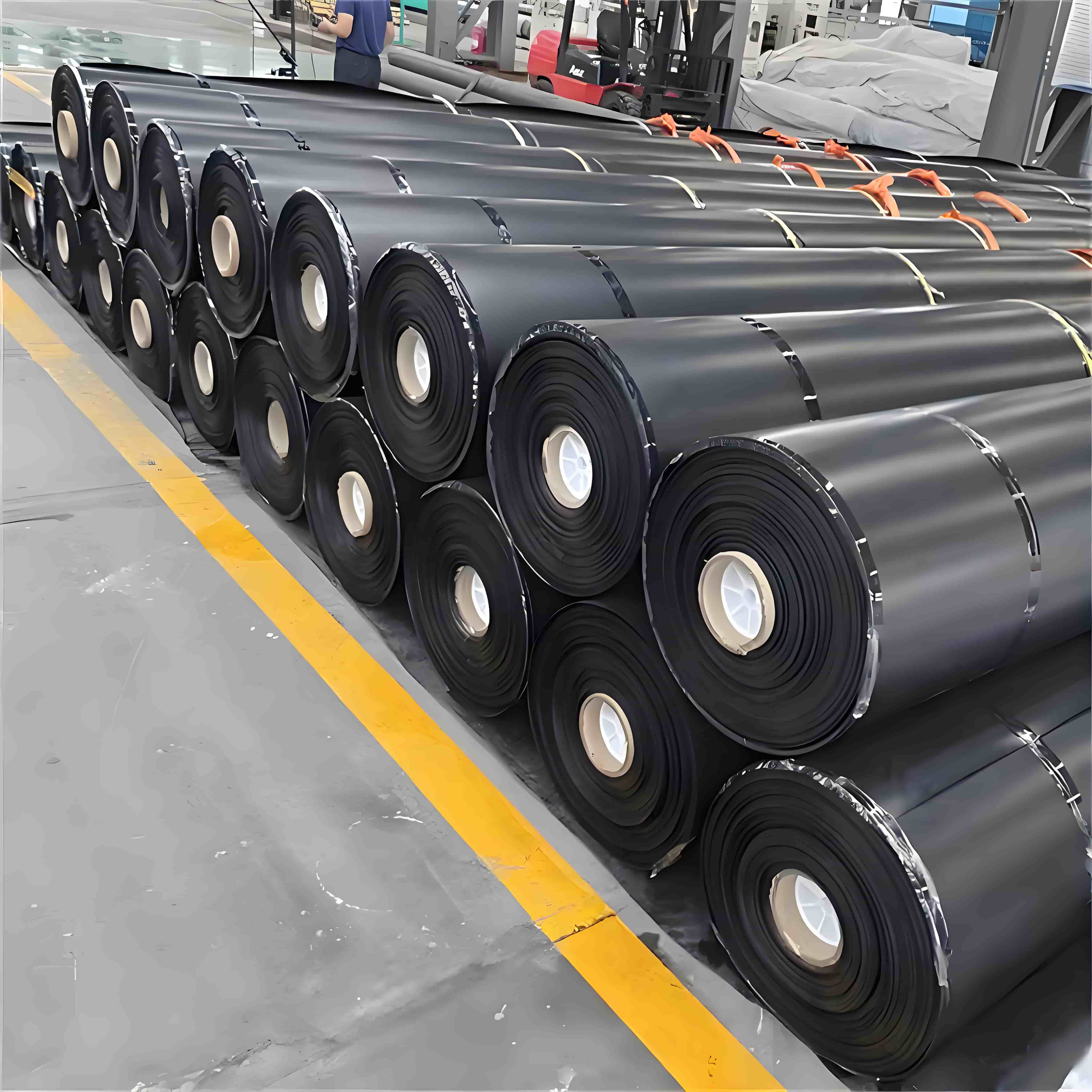

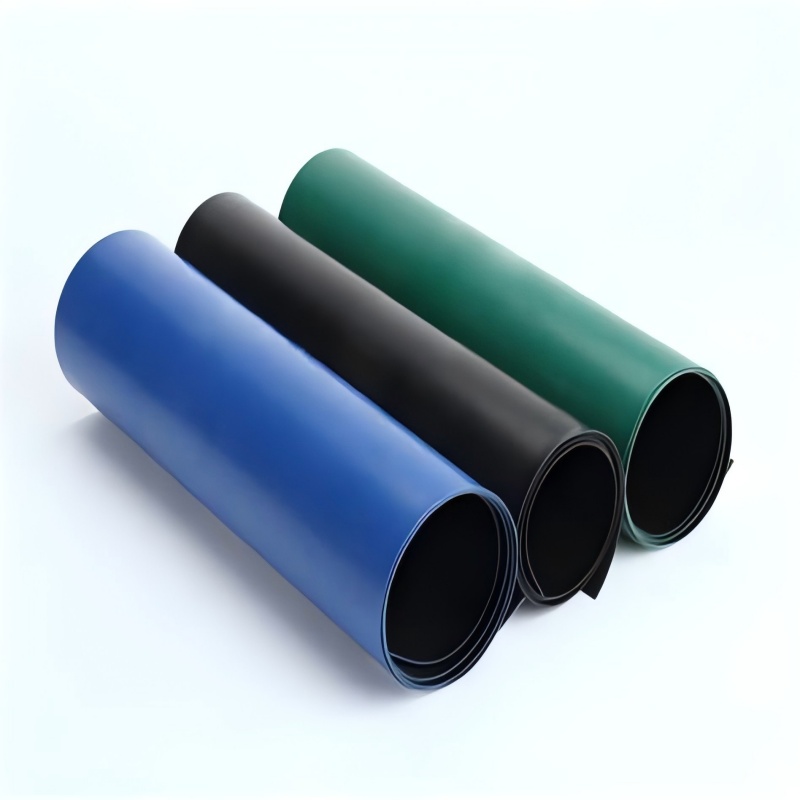

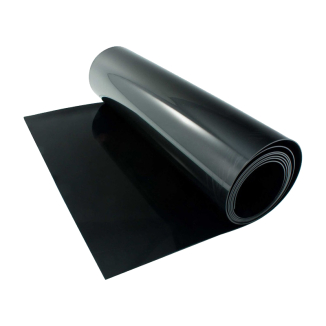

Prefabricated geomembrane is a polymer composite anti-seepage material produced through factory standardization. It is made of high-quality polymer substrates such as high-density polyethylene (HDPE) and ethylene vinyl acetate copolymer (EVA), and processed through special processes. Some products also have reinforced layers such as non-woven fabric and mesh cloth according to engineering requirements, forming a composite geomembrane with a multi-layer structure. It has completed pre-processing processes such as cutting and splicing before leaving the factory, and can be directly transported to the construction site for laying, greatly simplifying the tedious process of traditional geomembrane on-site processing. It is an efficient and reliable anti-seepage solution in modern civil engineering.

Product Features:

1. Excellent anti-seepage performance: The molecular structure of the prefabricated geomembrane substrate is dense, with extremely low porosity, which can effectively prevent the penetration of various liquids such as water, oil, and chemical solutions. After professional testing, its permeability coefficient can reach below 10 ⁻¹⁰ cm/s, far superior to traditional anti-seepage materials, ensuring that the project maintains good anti-seepage effect in long-term use, reducing the risk of structural damage and environmental pollution caused by leakage.

2. Excellent physical and mechanical properties: The product has high tensile strength, tear strength, and impact resistance, and can withstand pulling, rolling, and settlement deformation of engineering structures during construction. At the same time, it has excellent flexibility and can adapt to the laying needs of complex terrains. It is not easy to break when bent or folded, ensuring the structural integrity of the material under various working conditions.

3. Superb weather resistance and corrosion resistance: Prefabricated geomembranes can resist aging caused by long-term exposure to ultraviolet radiation, maintain stable performance in the temperature range of -40 ℃ to 60 ℃, and adapt to engineering environments in different climatic regions. In addition, it has good corrosion resistance to acidic, alkaline, salt and other chemical substances, and can be used for a long time in highly corrosive scenarios such as municipal sewage, industrial wastewater treatment, and landfill, with a service life of over 30 years.

4. Convenient and efficient construction: Due to the pre processing completed in the factory, the on-site laying process of prefabricated geomembranes is simple, only requiring splicing and fixing according to design requirements. Its lightweight and regular size can significantly reduce the labor intensity of construction personnel and shorten the construction period. Compared with traditional on-site production of anti-seepage materials, it can improve construction efficiency by more than 30% and reduce quality problems caused by improper on-site processing.

Product Parameters:

Metric | ASTM | unit | Test value | Minimum test frequency | ||||||

test method | 0.75 mm | 1.00 mm | 1.25 mm | 1.50 mm | 2.00 mm | 2.50mm | 3.00 mm | |||

Minimum average thickness | D5199 | mm | 0.75 | 1 | 1.25 | 1.5 | 2 | 2.5 | 3 | Per volume |

Minimum value (any one of 10) | -10% | -10% | -10% | -10% | -10% | -10% | -10% | |||

minimum density | D 1505/D 792 | g/cm3 | 0.94 | 0.94 | 0.94 | 0.94 | 0.94 | 0.94 | 0.94 | 90,000 kg |

Minimum average tensile performance (1) | D638 Type IV | |||||||||

Breakage strength, | N/mm | 20 | 27 | 33 | 40 | 53 | 67 | 80 | 9,000 kg | |

yield strength | N/mm | 11 | 15 | 18 | 22 | 29 | 37 | 44 | ||

Strain extension, | % | 700 | 700 | 700 | 700 | 700 | 700 | 700 | ||

yield extension | % | 12 | 12 | 12 | 12 | 12 | 12 | 12 | ||

Minimum strength of right-angle tear | D 1004 | N | 93 | 125 | 156 | 187 | 249 | 311 | 374 | 20,000 kg |

Minimum puncture strength | D4833 | N | 240 | 320 | 400 | 480 | 640 | 800 | 960 | 20,000 kg |

Constant tensile load stress cracking (2) | D5397 | hour | 300 | 300 | 300 | 300 | 300 | 300 | 300 | Based on GRI GM-10 |

Carbon black content | D 1603(3) | % | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 9,000 kg |

Carbon black dispersion | D5596 | Note (4) | Note (4) | Note (4) | Note (4) | Note (4) | Note (4) | Note (4) | 20,000 kg | |

Oxygen induction time (OIT) (5) | 90,000 kg | |||||||||

(a) Standard OIT | D3895 | minute | 100 | 100 | 100 | 100 | 100 | 100 | 100 | |

(b) high-handed OIT | D5885 | minute | 400 | 400 | 400 | 400 | 400 | 400 | 400 | |

85℃ Oven aging (minimum average) (5)(6) | Per formula | |||||||||

(A) Standard OIT is retained after 90 days | D 5721 | % | 55 | 55 | 55 | 55 | 55 | 55 | 55 | |

(B) High voltage OIT is retained for 90 days | D 3895 D5885 | % | 80 | 80 | 80 | 80 | 80 | 80 | 80 | |

Ultraviolet resistance (7) | Per formula | |||||||||

(a) standard OIT | D3895 | Note (8) 50 | ||||||||

(b) Retention of high pressure OIT after 1600 hours (9) | D5885 | % | ||||||||

Product Applications:

1. Water conservancy engineering: In water conservancy facilities such as reservoirs, dams, and channels, prefabricated geomembranes can be used for anti-seepage lining to prevent water leakage, improve the water storage efficiency and structural stability of water conservancy projects, and reduce safety hazards such as pipe surges and landslides caused by seepage in dams.

2. Municipal engineering: applicable to municipal projects such as sewage treatment plants, landfills, underground pipe galleries, etc. In sewage treatment plants, sedimentation tanks, oxidation ditches and other areas can be laid to prevent sewage leakage from polluting soil and groundwater; In landfills, an anti-seepage isolation layer can be formed to prevent the leakage of leachate and protect the surrounding ecological environment.

3. Transportation engineering: widely used in the anti-seepage layer of roadbeds, tunnels, and bridges of highways and railways. For example, laying prefabricated geomembranes in highway roadbeds can prevent groundwater from rising and soaking the roadbed, avoid problems such as roadbed settlement and overturning, and extend the service life of the road.

4. Mining engineering: used for anti-seepage treatment of mining tailings ponds, preventing heavy metal ions and harmful liquids in tailings slurry from penetrating into soil and groundwater, reducing the pollution of mining to the surrounding environment, and meeting environmental protection requirements.

Prefabricated geomembrane plays an irreplaceable role in many fields such as water conservancy, municipal engineering, transportation, mining, etc. due to its excellent anti-seepage performance, outstanding physical and mechanical properties, super weather resistance and corrosion resistance, as well as convenient and efficient construction. It not only ensures the structural safety and long-term stable operation of the project, but also reduces resource waste and environmental pollution, in line with the development concept of high efficiency, environmental protection, and economy in modern engineering construction. As an advanced anti-seepage material, prefabricated geomembranes provide reliable technical support for various projects and have broad application prospects and promotion value.