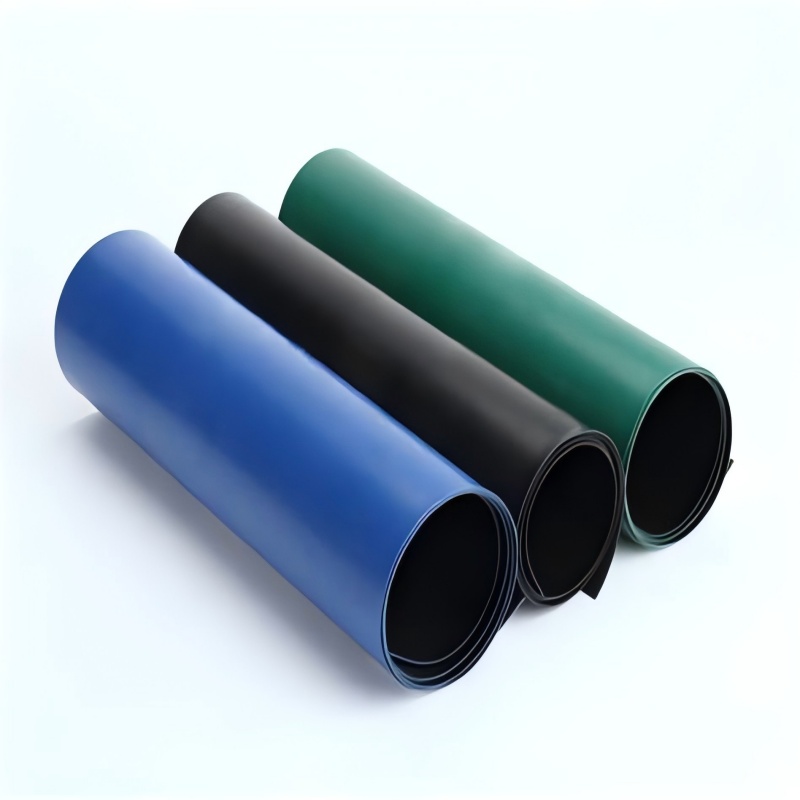

Geomembrana LDPE

1.Strong impermeability:The molecular structure is tight and uniform, which can efficiently block the infiltration of various liquids such as water and sewage, and reduce leakage problems in engineering from the root.

2.Corrosion resistance:Has good resistance to chemical substances such as acids, bases, and organic solvents, and can maintain stable performance in highly corrosive environments such as chemical engineering and wastewater treatment.

3.High intensity:Has excellent tensile and tear resistance, can withstand external impacts during construction and use, is not easily damaged, and ensures long-term stability of the project.

4.Convenient construction:Lightweight and flexible in texture, easy to transport, and can be easily laid in complex terrains, effectively shortening the construction period and reducing construction costs.

Product Introduction

Basic Attributes

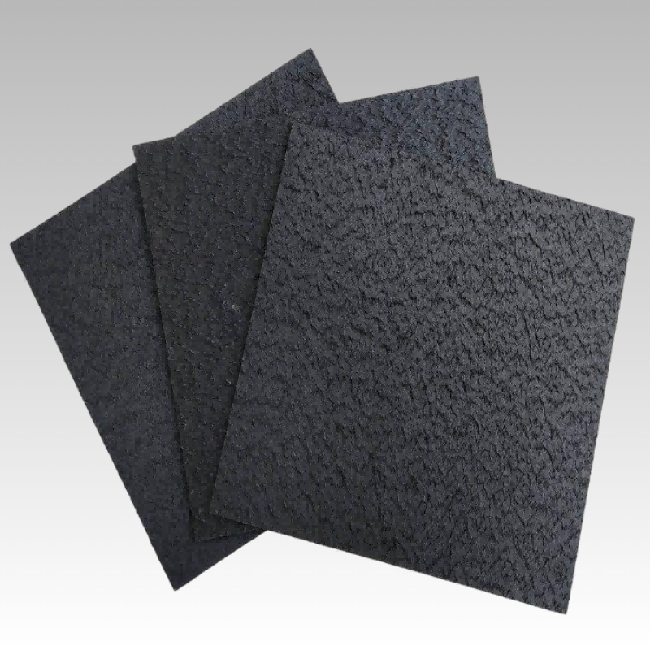

The raw materials for Geomembrana LDPE are mainly high molecular weight polymers such as high-density polyethylene, linear low-density polyethylene, and polypropylene. Some special types also add auxiliary materials such as antioxidants and ultraviolet absorbers to enhance their performance. The production process covers blow molding, rolling extrusion, composite processing, etc. Different processes can be used to produce various forms such as single film and composite film. The thickness of the finished film is usually between 0.2mm-3mm, with a flexible texture and uniform thickness. The molecules are arranged tightly and orderly, forming a continuous whole without pores. It can block liquid permeation channels from a physical structure and has certain high and low temperature resistance characteristics. It can maintain stable morphology in environments ranging from -40 ℃ to 60 ℃.

Core functions

The core function focuses on anti-seepage barrier and environmental protection. In hydraulic engineering, it can tightly block the leakage of water from reservoirs and channels to the dam body or soil, reducing the loss of water resources; In the field of environmental protection, it can effectively intercept the leachate generated by landfills and toxic and harmful substances in industrial wastewater tanks, preventing them from infiltrating underground and polluting soil and groundwater systems; In municipal construction, it is also possible to isolate the mixture of different media, such as preventing external seepage from entering the interior of underground pipe gallery projects, to ensure the safe operation of facilities. This multidimensional barrier effect makes it a key defense line for controlling liquid migration in engineering.

main features

In addition to its core anti-seepage ability, it has significant comprehensive performance advantages: strong corrosion resistance, good resistance to chemical substances such as acids, alkalis, salts, and organic solvents, and a service life of more than 10 years in highly corrosive environments such as chemical waste treatment plants and electroplating wastewater tanks; Excellent mechanical properties, with a tensile strength generally above 10MPa and a fracture elongation of over 200%. It can withstand the tension and compression caused by foundation settlement, construction compaction, etc., and has outstanding tear and puncture resistance. Even when impacted by sharp objects such as stones, it is not easily damaged; High construction adaptability, with a length of up to 50m-100m per roll and a weight of only 1/50 of the same area of concrete. The transportation cost is low, and it can be quickly joined by hot air welding, adhesive and other methods during laying. The joint strength can reach more than 80% of the base material, and it can flexibly fit in complex terrains such as steep slopes and curved surfaces, greatly shortening the construction period; Outstanding cost-effectiveness, compared to traditional concrete anti-seepage layers, not only is the initial material cost lower, but the maintenance cost in the later stage is also minimal, resulting in significant overall economic benefits.

Product Parameters

Metric | ASTM | unit | Test value | Minimum test frequency | ||||||

test method | 0.75 mm | 1.00 mm | 1.25 mm | 1.50 mm | 2.00 mm | 2.50mm | 3.00 mm | |||

Minimum average thickness | D5199 | mm | 0.75 | 1 | 1.25 | 1.5 | 2 | 2.5 | 3 | Per volume |

Minimum value (any one of 10) | -10% | -10% | -10% | -10% | -10% | -10% | -10% | |||

minimum density | D 1505/D 792 | g/cm3 | 0.94 | 0.94 | 0.94 | 0.94 | 0.94 | 0.94 | 0.94 | 90,000 kg |

Minimum average tensile performance (1) | D638 Type IV | |||||||||

Breakage strength, | N/mm | 20 | 27 | 33 | 40 | 53 | 67 | 80 | 9,000 kg | |

yield strength | N/mm | 11 | 15 | 18 | 22 | 29 | 37 | 44 | ||

Strain extension, | % | 700 | 700 | 700 | 700 | 700 | 700 | 700 | ||

yield extension | % | 12 | 12 | 12 | 12 | 12 | 12 | 12 | ||

Minimum strength of right-angle tear | D 1004 | N | 93 | 125 | 156 | 187 | 249 | 311 | 374 | 20,000 kg |

Minimum puncture strength | D4833 | N | 240 | 320 | 400 | 480 | 640 | 800 | 960 | 20,000 kg |

Constant tensile load stress cracking (2) | D5397 | hour | 300 | 300 | 300 | 300 | 300 | 300 | 300 | Based on GRI GM-10 |

Carbon black content | D 1603(3) | % | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 9,000 kg |

Carbon black dispersion | D5596 | Note (4) | Note (4) | Note (4) | Note (4) | Note (4) | Note (4) | Note (4) | 20,000 kg | |

Oxygen induction time (OIT) (5) | 90,000 kg | |||||||||

(a) Standard OIT | D3895 | minute | 100 | 100 | 100 | 100 | 100 | 100 | 100 | |

(b) high-handed OIT | D5885 | minute | 400 | 400 | 400 | 400 | 400 | 400 | 400 | |

85℃ Oven aging (minimum average) (5)(6) | Per formula | |||||||||

(A) Standard OIT is retained after 90 days | D 5721 | % | 55 | 55 | 55 | 55 | 55 | 55 | 55 | |

(B) High voltage OIT is retained for 90 days | D 3895 D5885 | % | 80 | 80 | 80 | 80 | 80 | 80 | 80 | |

Ultraviolet resistance (7) | Per formula | |||||||||

(a) standard OIT | D3895 | Note (8) 50 | ||||||||

(b) Retention of high pressure OIT after 1600 hours (9) | D5885 | % | ||||||||

Product Application

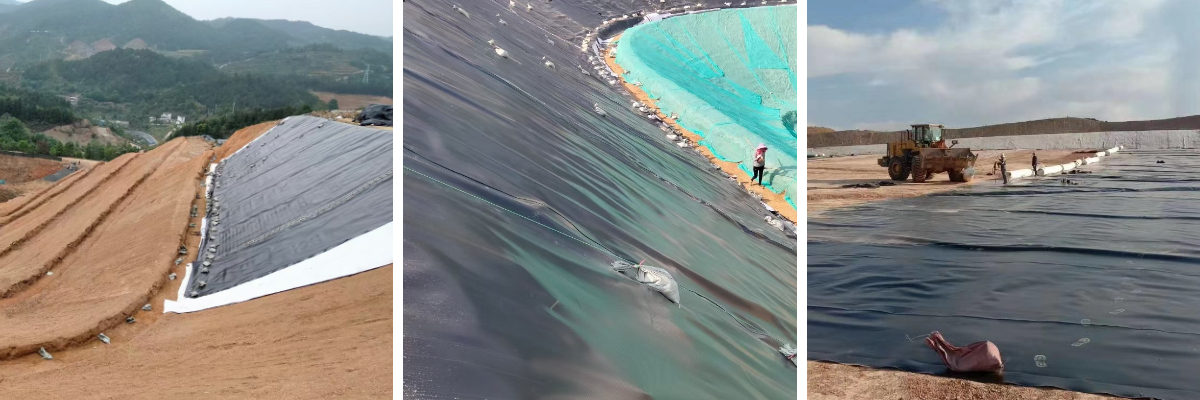

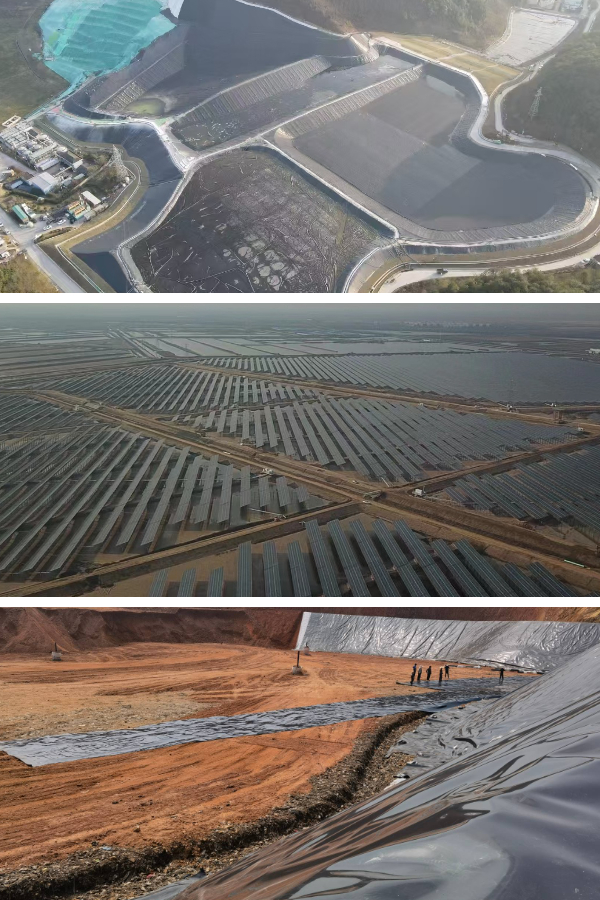

Water conservancy engineering

In the construction of reservoirs and dams, anti-seepage treatment is used for the dam body and bottom to reduce water leakage, ensure the water storage capacity and structural stability of water conservancy facilities; In channel engineering, it is laid at the bottom and slope of the channel to prevent water seepage and improve the utilization rate of irrigation water.

Environmental protection field

In landfills, as an anti-seepage layer, it prevents the infiltration of leachate into soil and groundwater, avoiding environmental pollution; In the sewage treatment plant, it is used to prevent leakage of facilities such as sedimentation tanks and regulating tanks, ensuring effective treatment of sewage and preventing secondary pollution.

Municipal construction

In underground pipe gallery engineering, it is laid around the pipe gallery to prevent water and seepage, and to protect the pipeline equipment inside the pipe gallery; In projects such as artificial lakes and landscape water pools, it is used for anti-seepage of the pool body, maintaining the water landscape effect, and reducing water resource loss.

In the field of agriculture

Mainly used in agricultural irrigation reservoirs, water channels, etc., it reduces water resource waste through anti-seepage, improves irrigation efficiency, and ensures the water supply required for crop growth.

Geomembranes, with their excellent anti-seepage performance, good adaptability, and reliable stability, safeguard the rational utilization of water resources in water conservancy projects, build ecological protection barriers in the field of environmental protection, ensure the safe operation of infrastructure in municipal construction, and help improve irrigation efficiency in agricultural production. Their widespread application not only provides key support for the smooth progress of various projects, but also plays an irreplaceable role in water resource protection, ecological environment maintenance, and other aspects.