Dewatering Geotube

1.Economical and Efficient:

Lower costs compared to traditional concrete or stone structures, with faster construction speed.

2.Environmentally Friendly:

Reduces excavation and consumption of construction materials, with the potential for recycling and reuse.

3.High Adaptability:

Suitable for complex terrains; flexible and capable of withstanding ground settlement.

4.Durability:

Designed with anti-aging properties, offering a service life of over 10 years.

Product Introduction:

Dewatering Geotube is a large tubular containment system made of high-strength geotextile fabric, widely used in civil engineering, environmental protection, and marine engineering.

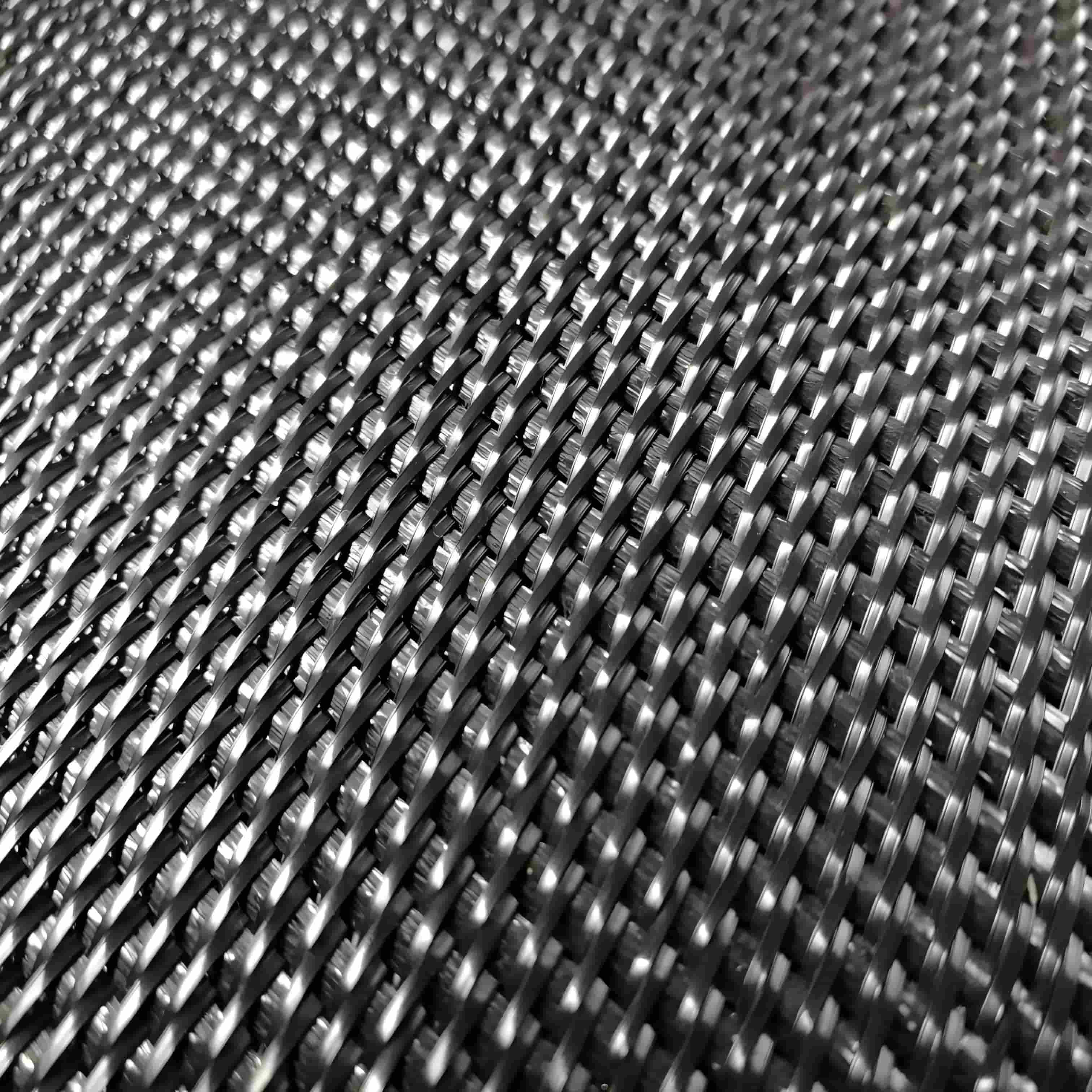

Material Properties

1.High Strength and Durability

Geotextile tubes are woven from high-performance fibers such as polypropylene, offering high tensile strength and low elongation to withstand significant soil and hydraulic pressures. Additionally, the material exhibits excellent resistance to UV rays, acids, alkalis, and microbial degradation, ensuring long-term performance in harsh environments.

2.Permeability and Filtration

The fabric features fine pores that allow water to pass through while retaining solid particles, enabling effective dewatering, consolidation, and pollutant filtration.

3.Customizability

The diameter, length, and shape of the tubes can be tailored to project requirements, with maximum lengths reaching several tens of meters, making them adaptable to diverse site conditions.

Product Parameters:

project | unit | CWGD50S | CWGD90/120 | CWGD90S | CWGD100S | CWGD120S-B | CWGD120S-C | CWGD130S | CWGD200S-C | |

Tensile strength-radial | kN/m | 55 | 90 | 90 | 100 | 130 | 130 | 130 | 220 | |

Tensile strength-Weft | 50 | 120 | 90 | 100 | 120 | 120 | 130 | 210 | ||

Strain elongation-radial | % | 16±1 | 12±1 | 9±1 | 10±1 | 10±1 | 10±1 | 10±1 | 12±1 | |

Extensional elongation-Weft | 10±1 | 8±1 | 8±1 | 8±1 | 8±1 | 8±1 | 8±1 | 8±1 | ||

Breakage strength at 2% elongation | warp direction | kN/m | 5/15 | 14/40 | 30/30 | 30/30 | 20/40 | 22/40 | 20/45 | 15 |

Breakage strength at 5% elongation | warp direction | kN/m | 14/33 | 38/90 | 75/75 | 75/75 | 80/100 | 84/40 | 80/110 | 90 |

mass area ratio | g/m² | 285 | 440 | 390 | 430 | 540 | 540 | 560 | 850 | |

Joint tensile strength | kN/m | 35 | 90 | 60 | 70 | 100 | 100 | 110 | 170 | |

Static Burst Strength (CBR) | KN | 5 | 10 | 10 | 13 | 15 | 15 | 16 | 22 | |

Dynamic perforation | mm | 10 | 8 | 12 | 12 | 10 | 10 | 11 | 8 | |

Equivalent aperture (0g0) | mm | 0.9 | 0.48 | 0.52 | 0.45 | 0.4 | 0.3 | 0.43 | 0.4 | |

Permeability (Q50) | L/m²/s | 200 | 40 | 20 | 15 | 12 | 6.5 | 15 | 15 | |

Ultraviolet resistance (500h strong storage rate ) | % | 90 | 90 | 85 | 85 | 85 | 85 | 85 | 85 | |

Product Applications:

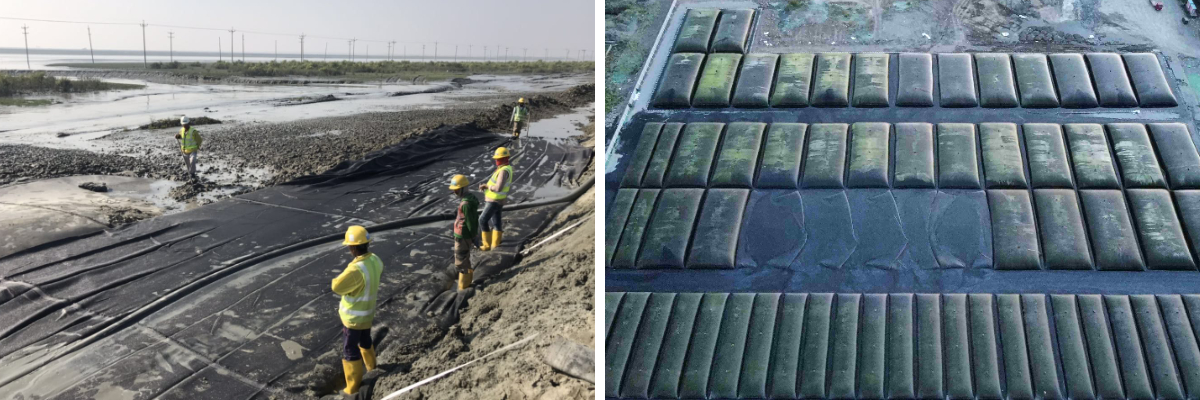

1.Water Conservancy Engineering:

Used in the construction of embankments, seawalls, and slope/bank protection in river regulation projects. Also applied for seepage control in cofferdams.

2.Environmental Governance:

Widely utilized in the treatment of dredged sediments from rivers, lakes, and seas, as well as municipal and industrial sludge. Effectively achieves sludge dewatering and solidification, reducing environmental pollution.

3.Marine Engineering:

Employed in land reclamation, artificial island construction, and coastal protection against marine erosion. Capable of forming artificial coastlines several kilometers long, where natural sedimentation of marine sand occurs behind the structures.

4.Soft Foundation Treatment:

Serves as a material for temporary access roads on soft foundations. By filling and dewatering the geotextile tubes to achieve solidification, a stable road foundation is formed.