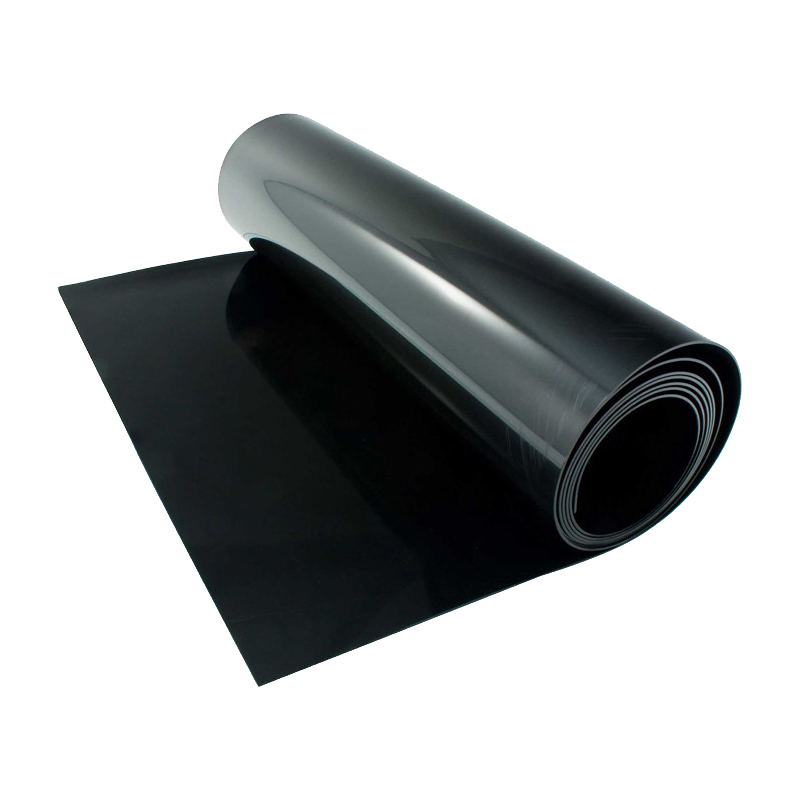

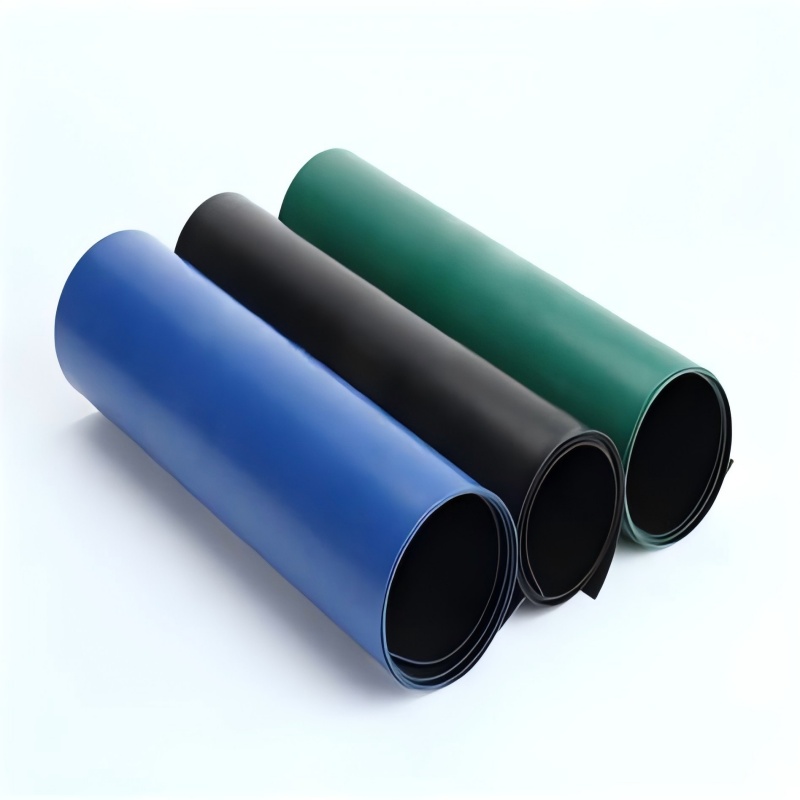

HDPE Pond Liner 1mm

1. High cost-effectiveness

Compared with traditional anti-seepage materials, geomembrane materials have lower costs, shorter construction periods, easier maintenance, and more comprehensive cost advantages.

2. Adapt to complex terrain

Good flexibility, can fit irregular terrain, especially suitable for engineering scenarios with complex geological conditions.

3. Controllable environmental protection

When selecting polymer materials that meet standards, they will not release harmful substances, do not pollute soil and water, and some products can be recycled.

4. Multifunctionality

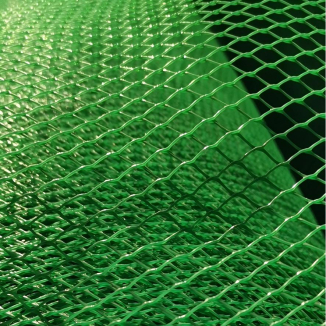

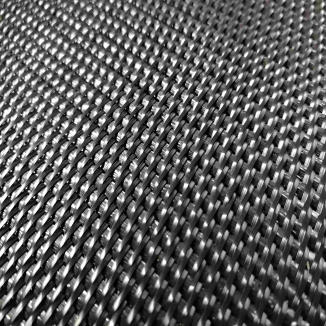

In addition to its core anti-seepage function, it can also be combined with materials such as geotextiles to form composite structures that serve functions such as isolation, drainage, and reinforcement, enhancing the overall performance of the project.

Product Introduction:

HDPE Pond Liner 1mm is a flexible waterproof barrier material made from high molecular weight polymers such as high-density polyethylene (HDPE), polyvinyl chloride (PVC), EVA, etc., through high-temperature melting, extrusion, or blow molding processes. Its core functions are anti-seepage, waterproofing, isolation, and reinforcement, widely used in civil engineering, water conservancy engineering, environmental engineering, and other fields, equivalent to covering engineering structures with a layer of "waterproof raincoat".

1. Excellent anti-seepage performance

Ultra low permeability coefficient

The anti-seepage coefficient can reach 1 × 10 ⁻¹⁷ cm/s (HDPE material), which is much lower than traditional materials (such as 1 × 10 ⁻⁷ cm/s of clay). It can effectively block the infiltration of liquids and gases, ensuring the long-term anti-seepage effect of the project.

Anti puncture and tear resistance

Smooth surface, low friction coefficient, reducing the risk of sharp object piercing; Simultaneously possessing high tensile strength (such as HDPE film tensile strength ≥ 17MPa), it can withstand external forces such as soil pressure and water flow impact.

2. Weather resistance and durability

Wide temperature range adaptability

Wide temperature range: -70 ℃ to 110 ℃, able to maintain stable physical properties even in extremely cold or high temperature environments.

UV resistance and anti-aging

Adding anti UV agents (such as carbon black) can result in a performance degradation of only 5% -10% after 20 years of exposure to sunlight, and a lifespan of up to 20-50 years.

3. Chemical stability

Anti acid and alkali corrosion

It has excellent tolerance to strong acids (pH=1), strong bases (pH=14), and salt solutions, and is suitable for lining chemical storage tanks and reaction tanks.

Anti oil stains and organic solvents

The non-polar molecular structure makes it insoluble in oil and can be exposed to diesel, gasoline, etc. for a long time without swelling or deformation.

4. High strength and flexibility

Tensile strength and elongation

The elongation at break is ≥ 450%, which can withstand deformation caused by foundation settlement or temperature changes without rupture.

Lightweight and flexible

Lightweight (about 0.9kg/㎡), bendable and foldable, easy to transport and lay; Can fit irregular base surfaces (such as slopes, curved surfaces).

5. Construction convenience

Quick laying and welding

By using hot melt welding or adhesive technology, the welding strength can reach over 90% of the base material, forming a continuous anti-seepage layer.

Adapt to complex working conditions

Construction can be carried out in humid and low-temperature environments (≥ -10 ℃) without the need for dry substrates or special equipment.

6. Environmental Protection and Safety

Non toxic and harmless materials

Compliant with environmental standards, it can be used in scenarios such as drinking water tanks and aquaculture.

Recyclable and Reusable

Waste geomembranes can be recycled and processed into plastic pellets, reducing environmental pollution and conforming to the concept of circular economy.

Product Parameters:

Metric | ASTM | unit | Test value | Minimum test frequency | ||||||

test method | 0.75 mm | 1.00 mm | 1.25 mm | 1.50 mm | 2.00 mm | 2.50mm | 3.00 mm | |||

Minimum average thickness | D5199 | mm | 0.75 | 1 | 1.25 | 1.5 | 2 | 2.5 | 3 | Per volume |

Minimum value (any one of 10) | -10% | -10% | -10% | -10% | -10% | -10% | -10% | |||

minimum density | D 1505/D 792 | g/cm3 | 0.94 | 0.94 | 0.94 | 0.94 | 0.94 | 0.94 | 0.94 | 90,000 kg |

Minimum average tensile performance (1) | D638 Type IV | |||||||||

Breakage strength, | N/mm | 20 | 27 | 33 | 40 | 53 | 67 | 80 | 9,000 kg | |

yield strength | N/mm | 11 | 15 | 18 | 22 | 29 | 37 | 44 | ||

Strain extension, | % | 700 | 700 | 700 | 700 | 700 | 700 | 700 | ||

yield extension | % | 12 | 12 | 12 | 12 | 12 | 12 | 12 | ||

Minimum strength of right-angle tear | D 1004 | N | 93 | 125 | 156 | 187 | 249 | 311 | 374 | 20,000 kg |

Minimum puncture strength | D4833 | N | 240 | 320 | 400 | 480 | 640 | 800 | 960 | 20,000 kg |

Constant tensile load stress cracking (2) | D5397 | hour | 300 | 300 | 300 | 300 | 300 | 300 | 300 | Based on GRI GM-10 |

Carbon black content | D 1603(3) | % | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 9,000 kg |

Carbon black dispersion | D5596 | Note (4) | Note (4) | Note (4) | Note (4) | Note (4) | Note (4) | Note (4) | 20,000 kg | |

Oxygen induction time (OIT) (5) | 90,000 kg | |||||||||

(a) Standard OIT | D3895 | minute | 100 | 100 | 100 | 100 | 100 | 100 | 100 | |

(b) high-handed OIT | D5885 | minute | 400 | 400 | 400 | 400 | 400 | 400 | 400 | |

85℃ Oven aging (minimum average) (5)(6) | Per formula | |||||||||

(A) Standard OIT is retained after 90 days | D 5721 | % | 55 | 55 | 55 | 55 | 55 | 55 | 55 | |

(B) High voltage OIT is retained for 90 days | D 3895 D5885 | % | 80 | 80 | 80 | 80 | 80 | 80 | 80 | |

Ultraviolet resistance (7) | Per formula | |||||||||

(a) standard OIT | D3895 | Note (8) 50 | ||||||||

(b) Retention of high pressure OIT after 1600 hours (9) | D5885 | % | ||||||||

Product Applications:

1. Environmental engineering

Landfill site: used as an anti-seepage liner to prevent leachate pollution.

Sewage treatment plant: The tank body is impermeable to prevent sewage leakage.

Biogas digester: The black film biogas digester is sealed with HDPE film to improve fermentation efficiency and reduce costs.

2. Water conservancy engineering

Reservoirs and dams: reduce leakage and improve water resource utilization efficiency. For example, the Three Gorges Reservoir uses geomembrane to reinforce the slope.

Irrigation channels: reduce water loss and improve irrigation efficiency.

3. Municipal engineering

Subway tunnel: anti-seepage lining to prevent groundwater intrusion.

Basement waterproofing: Ensure the building is dry and avoid structural corrosion.

4. Landscape Architecture

Artificial lakes and rivers: maintain water stability and prevent leakage.

Golf course: Pond anti-seepage, protecting lawn roots.

5. Agriculture and Mining

Aquaculture: prevent seepage in fish ponds, conserve water resources, and prevent the spread of diseases.

Washing pool and heap leaching pool: mining wastewater anti-seepage, protecting soil and water bodies.

6. Transportation facilities

Airports and highways: anti-seepage water storage and drainage systems ensure stable foundations.

Railway culverts: prevent rainwater erosion and extend their service life.

Geomembranes have become an indispensable waterproof material in modern engineering due to their excellent anti-seepage performance, durability, and adaptability. From environmental protection to agriculture, from municipal administration to transportation, its application scenarios continue to expand, providing strong support for sustainable development. Choosing geomembrane means choosing an efficient, economical, and environmentally friendly engineering solution.