Ditch Lining Material

1.Rapid Solidification and Early Strength

Starts solidifying within 2 hours after water contact, achieves C15 concrete standard (compressive strength ≥15MPa) within 24 hours, and reaches C30 (≥30MPa) at 7 days, suitable for emergency repair projects.

2.Excellent Waterproof and Anti-seepage Performance

The composite structure of high-density fibers and cement forms a seamless anti-seepage layer with a permeability coefficient ≤10⁻⁷ cm/s. It can replace geomembranes for anti-seepage in canals and ponds while providing load-bearing capacity.

3.Crack Resistance and Durability

High-strength fibers enhance toughness, with a flexural strength of 5MPa, enabling adaptation to slight foundation settlement without cracking. It has strong weather resistance, suitable for extremely cold or high-temperature regions.

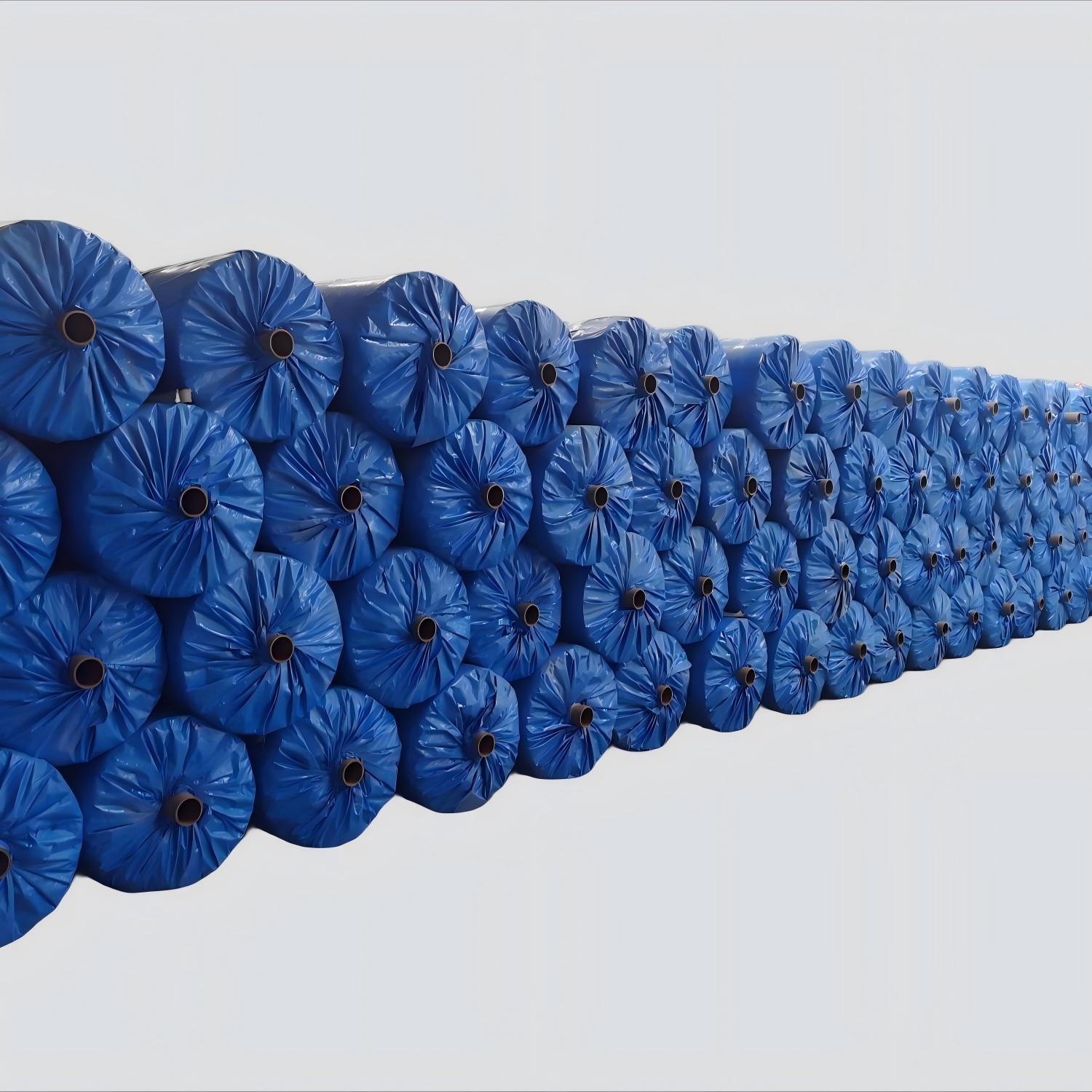

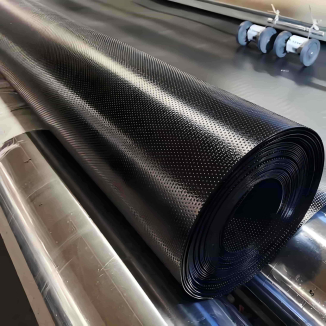

Product Introduction:

Ditch Lining Material is a flexible roll material composed of high-strength fibers (such as polypropylene or fiberglass) and special cement/additives through a needle-punching process. Its core structure consists of cementitious powder sandwiched between two layers of high-strength fiber mesh fabric. Upon hydration, the cement hardens to form a solid yet flexible matrix that combines the performance of concrete with the pliability of textiles—enabling rapid installation without traditional formwork or pouring methods.

Product Parameters:

| Property | State | 8mm | 10mm | 12mm | 15mm | Test Method | |

| Compressive strength(MPa) | cured 28 days | 60 MPa | D8329 | ||||

| Flexural strength(MPa) | cured 28 days | 15 MPa | D8058 | ||||

| Pyramid puncture(kN) | cured 28 days | 4.0 kN | 4.5 kN | 5.0 kN | 6.0 kN | D5494,Type B | |

| Abrasion (maximum value) | cured 28 days | 0.3 mm/1000 cycles | C1353/C1353M | ||||

| Tensile strength | Final | uncured | 20 kN/m | 30 kN/m | 35 kN/m | 40 kN/m | D6768/D6768M |

| Initial | cured 28 days | 15 kN/m | 25 kN/m | 30 kN/m | 35 kN/m | D4885 | |

| Final | 25 kN/m | 35 kN/m | 40 kN/m | 45 kN/m | |||

| Freeze-thaw | Residual initial flexural strenath(D8058) | cured 28 days, 200 cycles | >80 % (Pass) | C1185 | |||

| Water quality requirements for hydration | Tap water、River water、Seawater | / | |||||

| Construction temperature conditions | Construction above 0℃ | ||||||

| Fire protecting performance | B1 | GB 8624-2012 | |||||

| Harmful substance leaching test items | Limitation index (mg/L) | GB 5085.3-2007 | |||||

| Copper (total copper) (mg/L) | ≤100 | ||||||

| Zinc (total zinc) (mg/L) | ≤100 | ||||||

| Cadmium (total) (mg/L) | ≤1 | ||||||

| Lead (total lead) (mg/L) | ≤5 | ||||||

| Total chromium (mg/L) | ≤15 | ||||||

| Nickel (total nickel) | ≤5 | ||||||

| Arsenic (total) | ≤5 | ||||||

Application Areas

Product Advantages

The durability of the canvas of concrete performs well in medium - load, non - extreme environments (with a normal service life of 10 - 20 years), and it is especially suitable for short - term emergency projects, water conservancy seepage prevention, and building waterproofing scenarios. However, in long - term open - air, high - load, or highly corrosive environments, its durability is weaker than that of traditional concrete. Therefore, it is necessary to improve the service life through material modification and construction protection. When making a choice, a comprehensive assessment should be carried out according to the project cycle and environmental conditions, and if necessary, it should be used in combination with traditional materials.