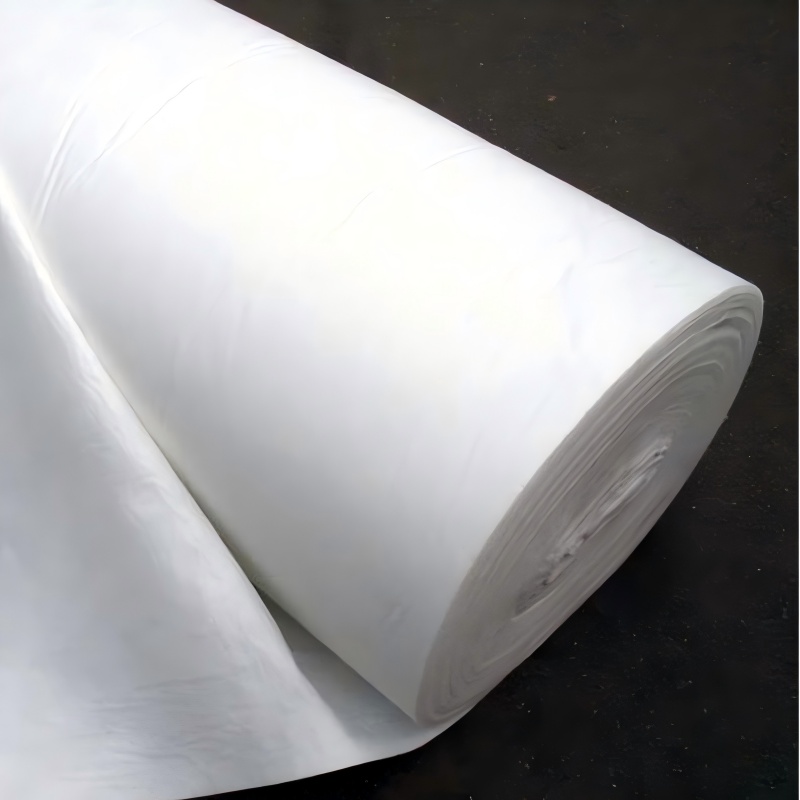

Geofabric for Roads

1. High strength: It has good tensile and tear resistance, and can enhance soil stability.

2. Permeability: allows water to pass through while preventing soil particle loss, playing a filtering role.

3. Corrosion resistance: acid and alkali resistance, mold resistance, suitable for various harsh environments.

4. Convenient construction: lightweight, easy to cut and lay, saving labor and time costs.

5. Economic and environmental protection: reduce the use of traditional materials, lower engineering costs, and minimize ecological damage.

Product Introduction:

Geofabric for Roads is a permeable geosynthetic material made from high molecular weight polymers (such as polypropylene, polyester, etc.) through processes such as needle punching, weaving, and weaving. It is mainly used in geotechnical engineering and civil engineering, playing a role in filtration, drainage, isolation, reinforcement, protection, etc. It is an important auxiliary material in modern engineering construction.

characteristic

1. Multifunctionality: It integrates multiple functions such as filtration, drainage, isolation, reinforcement, and protection, and can be used separately or in combination according to engineering needs to meet the technical requirements of different scenarios. For example, in roadbed engineering, it can both isolate different soil layers and drain accumulated water; In hydraulic engineering, embankments can be reinforced while preventing soil erosion.

2. Strong adaptability: It can be applied in various complex environments, such as high and low temperatures, humidity, saline alkali land, etc; The requirement for the flatness of the base layer is relatively low, and it can be stably laid on uneven surfaces.

3. Environmental friendliness: The polymer materials used are mostly recyclable or environmentally friendly, and will not cause pollution to soil, water sources, etc; No waste is generated during the construction process, which conforms to the concept of green engineering.

4. Good uniformity: Through industrial production, the physical properties of materials (such as thickness, strength, porosity) are evenly distributed, ensuring the stability and reliability of engineering quality.

Product Parameters:

project | metric | ||||||||||

Nominal strength/(kN/m) | |||||||||||

6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |||

1 | Longitudinal and transverse tensile strength / (kN/m) ≥ | 6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |

2 | Maximum elongation at maximum load in longitudinal and transverse directions/% | 30~80 | |||||||||

3 | CBR top penetration strength /kN ≥ | 0.9 | 1.6 | 1.9 | 2.9 | 3.9 | 5.3 | 6.4 | 7.9 | 8.5 | |

4 | Longitudinal and transverse tearing strength /kN | 0.15 | 0.22 | 0.29 | 0.43 | 0.57 | 0.71 | 0.83 | 1.1 | 1.25 | |

5 | Equivalent aperture O.90(O95)/mm | 0.05~0.30 | |||||||||

6 | Vertical permeability coefficient/(cm/s) | K× (10-¹~10-), where K=1.0~9.9 | |||||||||

7 | Width deviation rate /% ≥ | -0.5 | |||||||||

8 | Unit area mass deviation rate /% ≥ | -5 | |||||||||

9 | Thickness deviation rate /% ≥ | -10 | |||||||||

10 | Thickness coefficient of variation (CV)/% ≤ | 10 | |||||||||

11 | Dynamic perforation | Puncture hole diameter/mm ≤ | 37 | 33 | 27 | 20 | 17 | 14 | 11 | 9 | 7 |

12 | Longitudinal and transverse fracture strength (grab method)/kN ≥ | 0.3 | 0.5 | 0.7 | 1.1 | 1.4 | 1.9 | 2.4 | 3 | 3.5 | |

13 | Ultraviolet resistance (Xenon arc lamp method) | Longitudinal and transverse strength retention rate% ≥ | 70 | ||||||||

14 | Ultraviolet resistance (fluorescence UV lamp method) | Longitudinal and transverse strength retention rate% ≥ | 80 | ||||||||

Product Applications:

1. Transportation Engineering

Highway/railway subgrade: laying non-woven geotextile to isolate soft soil layers and fillers, prevent material mixing, and improve bearing capacity; In slope protection, short fiber needle punched geotextile is used to cover the slope surface, combined with grass planting to achieve ecological slope stabilization.

Airport runway: To prevent foundation settlement, for example, the runway of Shanghai Pudong International Airport is reinforced with long filament geotextile to reduce uneven settlement by up to 50%.

2. Water conservancy engineering

Dam anti filter layer: Long fiber geotextile is used as a filtering medium, allowing water flow to pass through but blocking sediment and protecting the dam structure. For example, in the Three Gorges Project, the coverage area of geotextile filter layer exceeds 1 million square meters.

Drainage system: Three dimensional geotextile is buried in soft soil areas to guide groundwater discharge and prevent roadbed collapse.

3. Environmental Protection Engineering

Landfill site: Composite geotextile (cloth+membrane) is used to construct an anti-seepage barrier, preventing pollutants from infiltrating groundwater, and improving the collection and drainage efficiency of leachate by 40%.

Sewage treatment tank: Geotextile is used as a protective material for the anti-seepage layer, extending the life of the tank body.

4. Municipal construction

Underground engineering: Textile geotextile reinforcement is used in subway tunnels to resist soil pressure deformation; In the construction of sponge cities, permeable geotextiles are laid on the lower layer of permeable road surfaces to enhance rainwater infiltration and storage capacity.

Greenbelt: Covering with geotextile to prevent weed growth and reduce maintenance costs.

5. Agricultural field

Farmland drainage ditch: Geotextile filters sediment to prevent blockage and improve drainage efficiency by 30%.

Greenhouse foundation reinforcement: Short fiber geotextile enhances the bearing capacity of the foundation and extends the service life of the greenhouse.

6. Ecological restoration

Polluted soil isolation: Short fiber cloth covers polluted soil to isolate harmful substances and promote vegetation restoration. For example, in mine restoration, the combination of geotextile and grass planting increases vegetation coverage from 20% to 80%.

Geotextile has become an indispensable material in modern engineering construction due to its advantages of high strength, permeability, corrosion resistance, and convenient construction. Its wide range of applications covers multiple fields such as civil engineering, water conservancy, and environmental protection, which can not only improve engineering quality but also reduce costs and environmental impact.