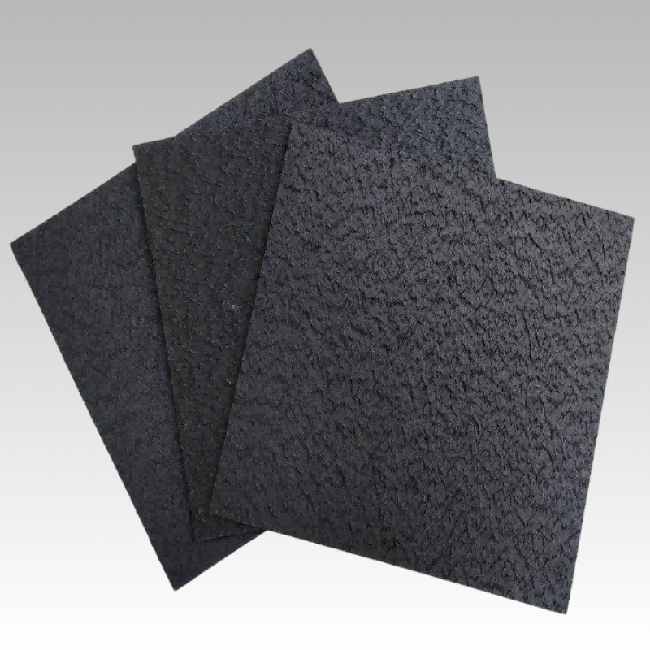

Geomembrana 1mm

1. Excellent anti-seepage performance:It can effectively block liquid infiltration and is suitable for scenarios such as water conservancy engineering and landfill sites, reducing water resource loss or pollutant leakage.

2. Strong weather resistance:UV resistance, high and low temperature resistance, stable performance can be maintained in different climatic environments, and the service life of the project can be extended.

3. High mechanical strength:Has good tensile strength and tear strength, can withstand external impact during construction and use, and is not easily damaged.

4. Convenient construction:Lightweight, flexible, easy to cut and lay, adaptable to complex terrains, and improves construction efficiency.

5. Good economic efficiency:Long service life, low maintenance cost, and higher overall cost-effectiveness compared to traditional anti-seepage materials.

Product Introduction

Basic properties of geomembrane

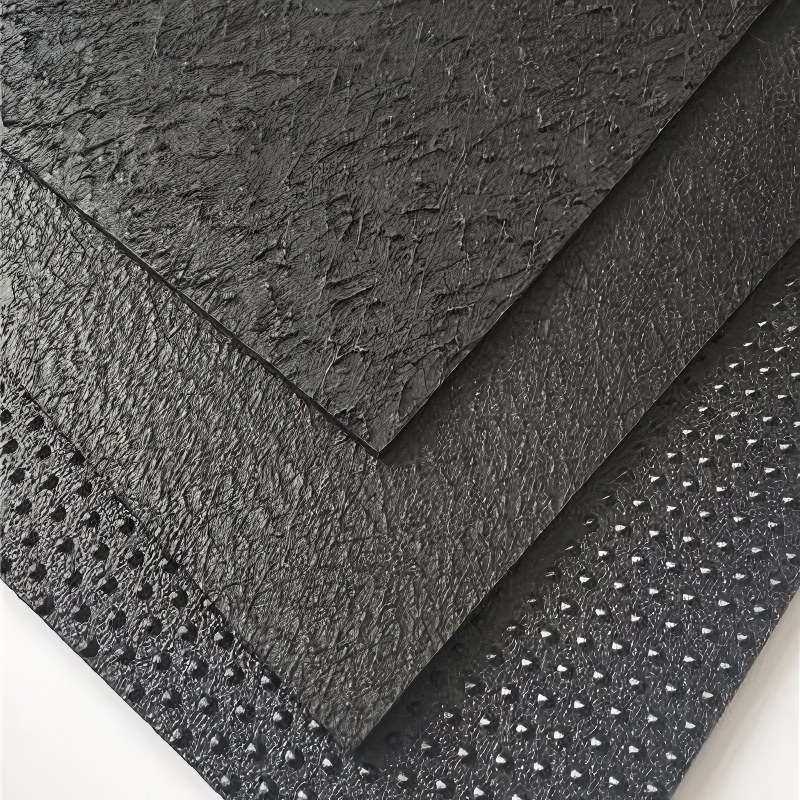

Geomembrana 1mm is a type of impermeable or low-permeability film material made mainly from high molecular weight polymers (such as polyethylene, polypropylene, polyvinyl chloride, etc.) through processes such as blow molding, rolling, and composite. It can also be formed by compounding fabrics with films to form composite geomembranes. Its basic attributes are mainly reflected in the following aspects:

Material characteristics: Polymer materials endow it with good chemical corrosion resistance, which can resist the erosion of industrial wastewater such as acid, alkali, and salt; At the same time, it has a certain degree of weather resistance and can maintain stable performance in natural environments such as ultraviolet radiation and high and low temperatures.

Physical properties: It has high tensile strength and tear strength, and can withstand external forces such as tension and compression during construction; The thickness is usually between 0.2mm-3mm, which can be selected according to engineering requirements. The thicker the thickness, the stronger the puncture resistance and durability.

Impermeability: This is one of its core physical properties, with an extremely low permeability coefficient (generally less than 1 × 10 ⁻⁹ cm/s), which can effectively prevent liquid leakage and is a key material for anti-seepage in water conservancy, environmental protection and other engineering projects.

The core function of geomembrane

The core function of geomembrane revolves around "anti-seepage, isolation, and protection", and is specifically applied in different engineering scenarios:

Anti leakage function: This is its most important function. In water conservancy projects such as reservoirs, dams, and channels, water leakage can be prevented to improve water resource utilization efficiency; In landfills, it can prevent leachate from seeping into soil and groundwater, avoiding environmental pollution; In projects such as artificial lakes and landscape water pools, water retention can be ensured to maintain the landscape effect.

Isolation function: It can separate materials of different properties to avoid mixing and affecting the stability of engineering structures. For example, in the construction of highway and railway subgrade, the subgrade soil and sand and gravel cushion layer can be isolated to prevent soil particles from infiltrating the cushion layer and causing structural deformation; In tailings pond engineering, the tailings can be isolated from the surrounding soil to prevent the spread of harmful substances.

Protective function: It can protect other materials in the project from damage. For example, laying geomembranes outside the anti-seepage layer of water conservancy dams can reduce the erosion of water flow on the anti-seepage layer; In the anti-seepage system of landfills, geomembranes can protect the underlying anti-seepage geomembrane (composite anti-seepage layer) from sharp garbage punctures.

Main characteristics of geomembrane

Geomembranes, with their unique materials and structure, have the following significant characteristics:

Construction convenience: Lightweight texture, much lower weight than traditional anti-seepage materials (such as concrete and clay), easy transportation and laying, and can shorten the construction period; The splicing process is mature and can achieve seamless connection through methods such as hot melt welding and adhesive bonding, ensuring anti-seepage effect while reducing construction difficulty.

Good economic efficiency: Although the unit area cost is higher than traditional materials such as clay, it has high construction efficiency, low maintenance costs in the later stage, and a long service life (generally up to 30-50 years), making it more cost-effective than traditional anti-seepage solutions; Especially in large-scale projects, it can significantly reduce the total cost.

Wide adaptability: Strong adaptability to terrain and landforms, suitable for laying on irregular surfaces such as steep slopes and depressions, and applicable to various complex geological conditions; At the same time, it can adapt to the needs of different types of engineering, whether it is water conservancy, municipal, environmental protection or transportation engineering, and can play its role in anti-seepage and isolation.

Environmental safety: The polymer materials used have stable chemical properties, are non-toxic, and will not cause pollution to the surrounding environment; In environmental protection projects such as landfills and sewage treatment plants, it can effectively block the migration of pollutants, protect the ecological environment, and meet the requirements of green engineering.

Product Parameters

Metric | ASTM | unit | Test value | Minimum test frequency | ||||||

test method | 0.75 mm | 1.00 mm | 1.25 mm | 1.50 mm | 2.00 mm | 2.50mm | 3.00 mm | |||

Minimum average thickness | D5199 | mm | 0.75 | 1 | 1.25 | 1.5 | 2 | 2.5 | 3 | Per volume |

Minimum value (any one of 10) | -10% | -10% | -10% | -10% | -10% | -10% | -10% | |||

minimum density | D 1505/D 792 | g/cm3 | 0.94 | 0.94 | 0.94 | 0.94 | 0.94 | 0.94 | 0.94 | 90,000 kg |

Minimum average tensile performance (1) | D638 Type IV | |||||||||

Breakage strength, | N/mm | 20 | 27 | 33 | 40 | 53 | 67 | 80 | 9,000 kg | |

yield strength | N/mm | 11 | 15 | 18 | 22 | 29 | 37 | 44 | ||

Strain extension, | % | 700 | 700 | 700 | 700 | 700 | 700 | 700 | ||

yield extension | % | 12 | 12 | 12 | 12 | 12 | 12 | 12 | ||

Minimum strength of right-angle tear | D 1004 | N | 93 | 125 | 156 | 187 | 249 | 311 | 374 | 20,000 kg |

Minimum puncture strength | D4833 | N | 240 | 320 | 400 | 480 | 640 | 800 | 960 | 20,000 kg |

Constant tensile load stress cracking (2) | D5397 | hour | 300 | 300 | 300 | 300 | 300 | 300 | 300 | Based on GRI GM-10 |

Carbon black content | D 1603(3) | % | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 9,000 kg |

Carbon black dispersion | D5596 | Note (4) | Note (4) | Note (4) | Note (4) | Note (4) | Note (4) | Note (4) | 20,000 kg | |

Oxygen induction time (OIT) (5) | 90,000 kg | |||||||||

(a) Standard OIT | D3895 | minute | 100 | 100 | 100 | 100 | 100 | 100 | 100 | |

(b) high-handed OIT | D5885 | minute | 400 | 400 | 400 | 400 | 400 | 400 | 400 | |

85℃ Oven aging (minimum average) (5)(6) | Per formula | |||||||||

(A) Standard OIT is retained after 90 days | D 5721 | % | 55 | 55 | 55 | 55 | 55 | 55 | 55 | |

(B) High voltage OIT is retained for 90 days | D 3895 D5885 | % | 80 | 80 | 80 | 80 | 80 | 80 | 80 | |

Ultraviolet resistance (7) | Per formula | |||||||||

(a) standard OIT | D3895 | Note (8) 50 | ||||||||

(b) Retention of high pressure OIT after 1600 hours (9) | D5885 | % | ||||||||

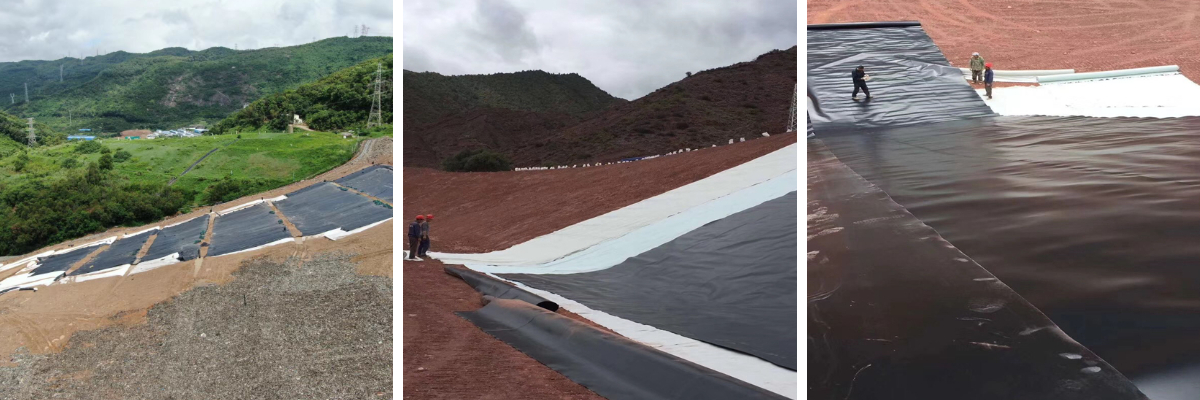

Product Application

Water conservancy engineering

In the construction of reservoirs and dams, geomembranes form continuous anti-seepage barriers, effectively blocking water infiltration, reducing safety hazards caused by dam leakage, and ensuring the water storage capacity of water conservancy facilities; When laying channels, their smooth surface can also reduce water flow resistance, improve water transmission speed while reducing water leakage rate. In large-scale water transmission projects such as the South to North Water Diversion Project, their excellent performance greatly improves water resource utilization efficiency.

Environmental Protection and Municipal Administration

In landfill sites, geomembranes are tightly attached to the bottom and surrounding areas of the landfill site, which can firmly lock in the leachate and prevent it from seeping into the soil and groundwater, causing pollution and building a strong defense line for the surrounding ecological environment; After the installation of the tank body and sludge storage area in the sewage treatment plant, it can avoid secondary pollution caused by the leakage of sewage and sludge, and reduce the cost of environmental treatment; Municipal utility tunnels and storage tanks rely on their reliable waterproof performance to protect internal pipeline equipment from groundwater erosion and ensure long-term stable operation of municipal facilities.

Transportation Engineering

Laying geomembranes on highway and railway roadbeds can effectively isolate soil layers of different properties, prevent fine particles from mixing into the roadbed filling, thereby reducing road settlement and deformation, and extending the service life of the road; In the construction of tunnels and culverts, their anti-seepage effect can effectively prevent groundwater from infiltrating into the internal structure, avoid water accumulation affecting driving safety, and reduce the frequency of tunnel maintenance.

Mining Agriculture

Laying geomembranes in mining tailings ponds can completely isolate tailings containing harmful substances such as heavy metals from surrounding soil and water bodies, prevent the spread of pollutants, and protect the surrounding ecological environment; After the installation of irrigation channels and reservoirs in the agricultural field, in addition to reducing water resource waste, it can also prevent channel collapse and water leakage, ensure stable water sources for crop growth, and help promote efficient agricultural production.

Geomembranes have important applications in water conservancy, environmental protection, transportation, mining, agriculture and other fields due to their excellent anti-seepage and isolation performance. It not only reduces various risks by improving the stability and safety of engineering, but also plays an irreplaceable positive role in water conservation, consumption reduction, environmental protection, and other aspects, becoming a key material for ensuring quality and efficiency in modern engineering construction.