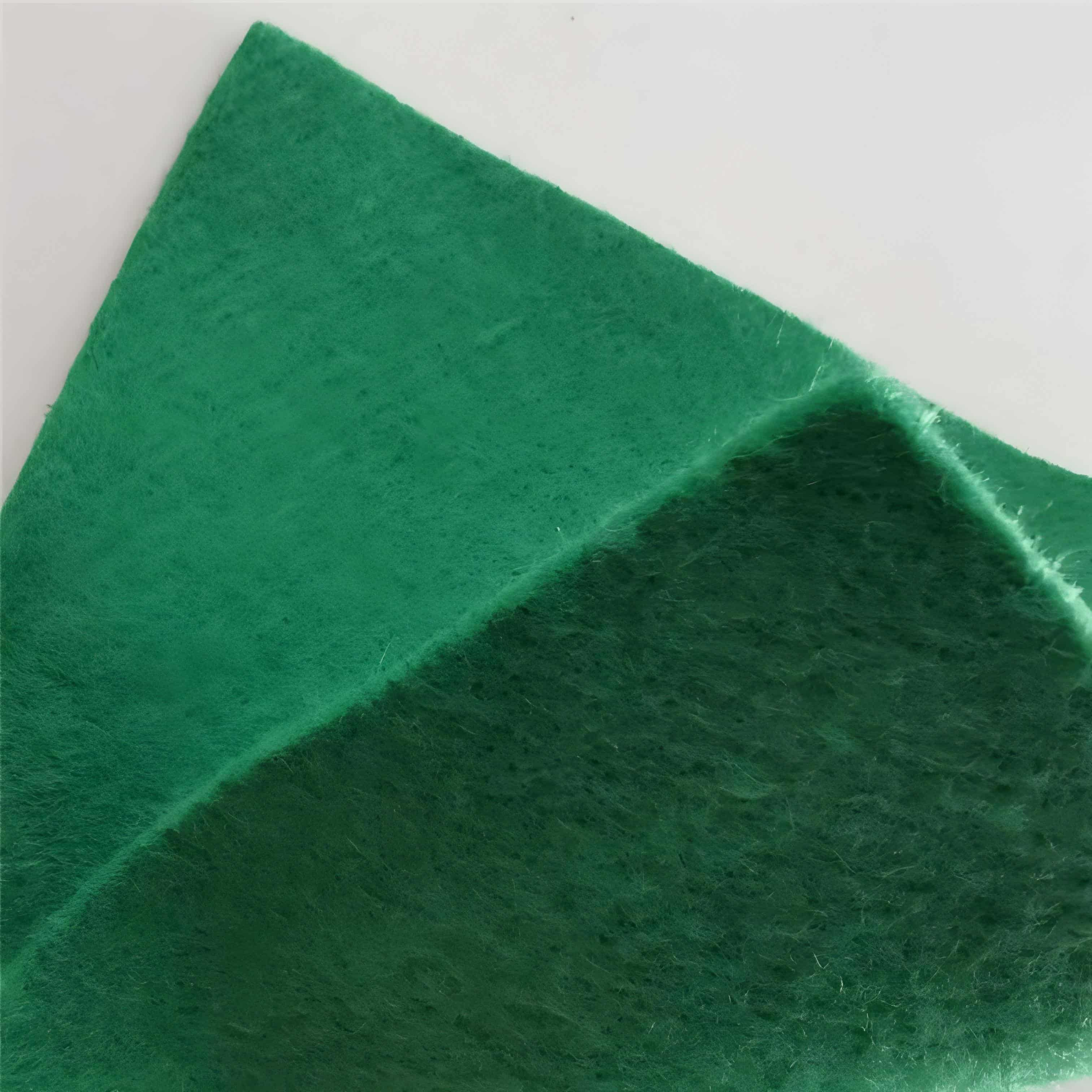

Geotextile 200 Gr m2

1. Efficiency:

High filtration and drainage efficiency, capable of quickly draining accumulated water from the soil, reducing pore water pressure, and protecting engineering structures. Convenient construction, light weight, fast laying speed, and can shorten the construction period.

2. Economy:

The material cost is lower than that of traditional sand and gravel filter layers, and it reduces the amount of earthwork and transportation costs. Strong durability, long service life, and reduced maintenance costs in the later stage.

3. Environmental friendliness:

Synthetic fiber materials can be recycled, and some products use environmentally friendly raw materials to reduce damage to the natural environment.

Product Introduction:

Geotextile 200 Gr m2 is a permeable geosynthetic material made from synthetic fibers such as polyester (PET) and polypropylene (PP) through needle punching, weaving, or thermal bonding processes. Its finished products are in the form of cloth and are divided into two categories: woven geotextiles and non-woven long filament geotextiles. As a core member of the geotextile material family, geotextile silently supports the safety and stability of modern engineering with its role as an "invisible protective net".

characteristic

1. High strength and ductility

Made of plastic fiber material, it can maintain sufficient strength and elongation in both dry and wet conditions, with high tensile strength and the ability to withstand large tensile forces without easily breaking. For example, in slope reinforcement, geotextiles can enhance soil tension like "invisible steel bars" and reduce landslide risks.

2. Corrosion resistance and aging resistance

Long term corrosion resistance in soil and water of different pH levels, as well as resistance to microorganisms and insect infestations, with a service life of several decades. This characteristic makes it the preferred material in water conservancy and environmental engineering.

3. Permeability and Filtration

There are gaps between fibers that allow water to pass through but block soil particles, forming natural drainage channels. For example, in dam engineering, geotextiles can quickly drain groundwater and prevent the foundation from being softened by rainwater.

4. Convenient construction and low cost

The material is soft and easy to transport, cut, and lay, and can be manually operated. Meanwhile, its cost is much lower than traditional materials such as concrete and steel, significantly reducing the total investment of the project.

5. Environmentally friendly and non-toxic

Geotextile is a high molecular weight polymer material that is non-toxic and odorless, and does not pose any harm to human health or the environment, in line with the concept of green engineering.

Product Parameters:

project | metric | ||||||||||

Nominal strength/(kN/m) | |||||||||||

6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |||

1 | Longitudinal and transverse tensile strength / (kN/m) ≥ | 6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |

2 | Maximum elongation at maximum load in longitudinal and transverse directions/% | 30~80 | |||||||||

3 | CBR top penetration strength /kN ≥ | 0.9 | 1.6 | 1.9 | 2.9 | 3.9 | 5.3 | 6.4 | 7.9 | 8.5 | |

4 | Longitudinal and transverse tearing strength /kN | 0.15 | 0.22 | 0.29 | 0.43 | 0.57 | 0.71 | 0.83 | 1.1 | 1.25 | |

5 | Equivalent aperture O.90(O95)/mm | 0.05~0.30 | |||||||||

6 | Vertical permeability coefficient/(cm/s) | K× (10-¹~10-), where K=1.0~9.9 | |||||||||

7 | Width deviation rate /% ≥ | -0.5 | |||||||||

8 | Unit area mass deviation rate /% ≥ | -5 | |||||||||

9 | Thickness deviation rate /% ≥ | -10 | |||||||||

10 | Thickness coefficient of variation (CV)/% ≤ | 10 | |||||||||

11 | Dynamic perforation | Puncture hole diameter/mm ≤ | 37 | 33 | 27 | 20 | 17 | 14 | 11 | 9 | 7 |

12 | Longitudinal and transverse fracture strength (grab method)/kN ≥ | 0.3 | 0.5 | 0.7 | 1.1 | 1.4 | 1.9 | 2.4 | 3 | 3.5 | |

13 | Ultraviolet resistance (Xenon arc lamp method) | Longitudinal and transverse strength retention rate% ≥ | 70 | ||||||||

14 | Ultraviolet resistance (fluorescence UV lamp method) | Longitudinal and transverse strength retention rate% ≥ | 80 | ||||||||

Product Applications:

1. Transportation Engineering

Railway/Highway: As a roadbed reinforcement material, isolation layer or crack prevention material, it delays the occurrence of pavement cracks and enhances the bearing capacity of the foundation.

Airport runway: laid between the runway and the foundation to prevent uneven settlement.

2. Water conservancy engineering

Embankment/Slope Protection: Resist water erosion and protect structural integrity.

Water well/relief well: serves as a filter layer to prevent sediment blockage.

3. Environmental Protection Engineering

Landfill site: Wrap waste to prevent soil contamination by leachate.

Mining beneficiation: As a drainage material, it improves drainage efficiency.

4. Municipal engineering

Artificial Lake/Landscape Pool: Isolate the soil from the waterproof layer to prevent punctures.

Underground pipe gallery: a filter layer around the drainage hidden pipe to avoid blockage.

5. Civil field

Garden vegetable field: laid on the surface of the soil to inhibit weed growth, breathable and permeable.

Roof waterproofing: Temporary covering of leakage points to guide rainwater drainage.

Moving and storage: Package fragile items, scratch resistant and shock-absorbing.

From the "hardcore responsibility" of supporting thousands of miles of highways to the "life assistant" of entering thousands of households, geotextiles have become an indispensable "invisible guardian" in modern engineering due to their practicality, multifunctionality, and environmental friendliness. In the future, with the continuous advancement of material technology, the application fields of geotextiles will be further expanded, continuously creating a safer and more sustainable living environment for humanity.