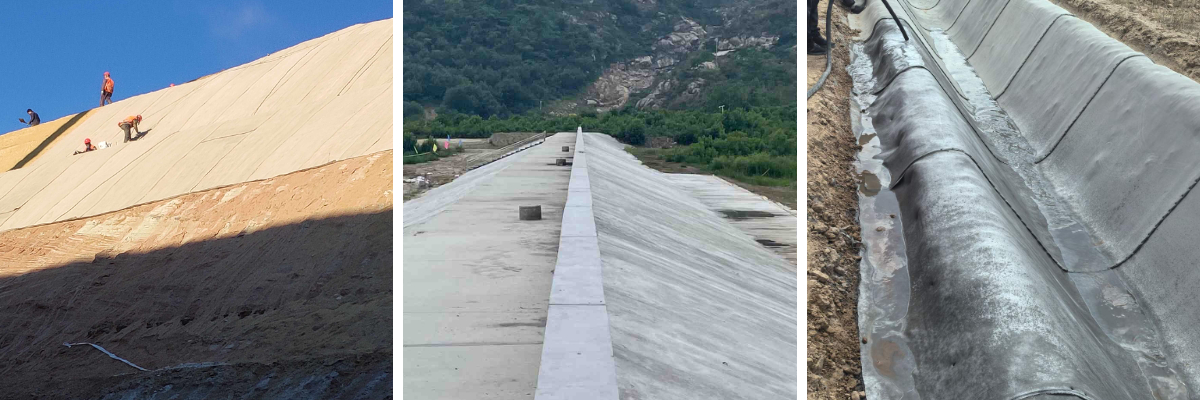

Concrete Ditch Liner

1.Unparalleled Speed and Ease of Installation: This is its most significant advantage. There is no need for mixing plants, concrete trucks, or heavy formwork. A small team can unroll, cut, position, and hydrate large areas in a fraction of the time required for poured-in-place concrete. This leads to dramatically reduced labor costs and project timelines.

2.Excellent Flexibility and Conformability: Unlike rigid concrete panels, cement blanket can easily drape over irregular surfaces, corners, and curves. It can be seamlessly formed to the contours of ditches, slopes, pipes, and embankments without the need for complex carpentry or cutting.

3.Rapid Strength Gain: The specialized cement formulation allows it to achieve high early strength. It can often withstand foot traffic within 24 hours and vehicle traffic soon after, minimizing downtime for critical infrastructure like roads and pipelines.

Product Introduction:

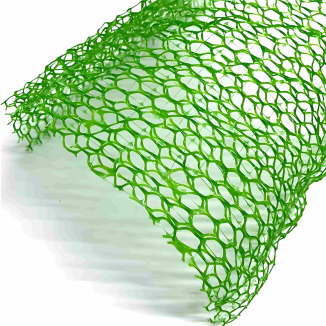

Concrete Ditch Liner is a soft fabric impregnated with cement, mainly composed of a three-dimensional fiber composite structure woven from polyethylene and polypropylene filaments, containing a special formula of dry concrete mixture, and covered with a polyvinyl chloride lining on the bottom surface. After encountering water, hydration reaction occurs, forming a thin and durable concrete layer.

Feature

Easy to use: The cement blanket can be provided in rolls, making it convenient for manual loading, unloading, and transportation without the need for large lifting machinery. Concrete is prepared according to scientific proportions and does not require on-site mixing. It can solidify and form both underwater and in seawater.

Rapid solidification molding: After watering and hydration reaction, its size and shape can still be processed within 2 hours, and it can harden to 80% strength within 24 hours. It can also achieve rapid solidification or delayed solidification through special formulas.

Environmentally friendly: Cement blanket is a low-quality and low-carbon technology that uses 95% less material than commonly used concrete in many applications. Its alkali content is limited, the erosion rate is very low, and it has little impact on the local ecology.

Flexibility of application: Cement blankets have good drape and can conform to the complex shapes of the covered object surface, even forming a hyperbolic shape. Before solidification, they can be cut or trimmed freely with ordinary hand tools.

High material strength: The fibers in the cement blanket enhance the material's strength, prevent cracking, and absorb impact energy.

Long term durability: It has good chemical resistance, resistance to wind and rain erosion, and will not undergo UV degradation even in sunlight.

Waterproof characteristics: The bottom of the cement blanket has a waterproof layer, making it completely waterproof and enhancing the material's chemical resistance.

Product Parameters:

Property | State | 8mm | 10mm | 12mm | 15mm | Test Method | |

Compressive strength(MPa) | cured 28 days | 60 MPa | D8329 | ||||

Flexural strength(MPa) | cured 28 days | 15 MPa | D8058 | ||||

Pyramid puncture(kN) | cured 28 days | 4.0 kN | 4.5 kN | 5.0 kN | 6.0 kN | D5494,Type B | |

Abrasion (maximum value) | cured 28 days | 0.3 mm/1000 cycles | C1353/C1353M | ||||

Tensile strength | Final | uncured | 20 kN/m | 30 kN/m | 35 kN/m | 40 kN/m | D6768/D6768M |

Initial | cured 28 days | 15 kN/m | 25 kN/m | 30 kN/m | 35 kN/m | D4885 | |

Final | 25 kN/m | 35 kN/m | 40 kN/m | 45 kN/m | |||

Freeze-thaw | Residual initial flexural | cured 28 days, 200 cycles | >80 % (Pass) | C1185 | |||

Water quality requirements for hydration | Tap water、River water、Seawater | / | |||||

Construction temperature conditions | Construction above 0℃ | ||||||

Fire protecting performance | B1 | GB 8624-2012 | |||||

Harmful substance leaching test items | Limitation index (mg/L) | GB 5085.3-2007 | |||||

Copper (total copper) (mg/L) | ≤100 | ||||||

Zinc (total zinc) (mg/L) | ≤100 | ||||||

Cadmium (total) (mg/L) | ≤1 | ||||||

Lead (total lead) (mg/L) | ≤5 | ||||||

Total chromium (mg/L) | ≤15 | ||||||

Nickel (total nickel) | ≤5 | ||||||

Arsenic (total) | ≤5 | ||||||

Product Applications:

1. Water conservancy and soil and water conservation engineering

This is the most classic application field of cement blankets.

Channel lining: used for anti-seepage lining of irrigation channels and drainage ditches, with fast construction speed and good anti erosion and anti-seepage effects.

Slope protection: used for slope protection of reservoirs, riverbanks, and dirt roads to prevent soil erosion. It can perfectly adhere to the slope and form a strong protective layer after curing.

Pit and pond anti-seepage: used for bottom anti-seepage treatment of small reservoirs, fish ponds, and septic tanks.

2. Municipal and Landscape Architecture

Drainage ditch: Quickly construct temporary or permanent drainage ditches within the site.

Pedestrian trail: a walking path used in parks and green belts, which can shape curved shapes and have a natural appearance.

Foundation cushion layer: It can be used as a foundation cushion layer for some lightweight structures, providing a flat and sturdy foundation.

Water landscape engineering: used to shape artificial streams, waterfall pools, etc., easy to form and waterproof.

3. Construction Engineering and Foundation Treatment

Roof flat to sloping cushion layer: laid on roofs that require a slope as a strong cushion layer before the waterproof layer.

Ground hardening: used for rapid hardening of basement and factory floors, with moisture-proof function.

Pipe gallery wrapping: wraps underground pipelines to provide anti-corrosion and mechanical protection.

4. Transportation and Road Engineering

Rapid road repair: Emergency repair of road potholes and roadbed subsidence can quickly restore traffic.

Railway embankment slope protection: Strengthen the soil slopes along the railway line.

Temporary access road: Quickly lay a temporary passage on soft ground or sandy land for vehicles to pass through.

5. Emergency rescue and military engineering

This is the ultimate manifestation of leveraging its "fast" advantage.

Flood control and emergency response: Quickly raise and reinforce dams, block pipe surges and breaches.

Firefighting passage: Quickly lay emergency passages leading to water sources at the scene of a fire.

Military bunker: Quickly construct ground and slope protection for field fortifications and command posts, facilitating transportation and construction.

Post disaster reconstruction: used for the rapid construction of temporary facilities after earthquakes, floods, and other disasters.

6. Special and Industrial Applications

Mine management: used for slope protection and dust suppression of tailings dams and slag yards.

In the field of oil and gas fields: laid in well sites and work areas to prevent muddy ground and facilitate operations.

Firewall: It can be used to quickly build temporary firewalls in factories or warehouses.

In summary, Concrete Ditch Liner is a revolutionary material that solves many pain points of traditional concrete in terms of efficiency, shape, and on-site conditions, providing a new and efficient solution for engineering.