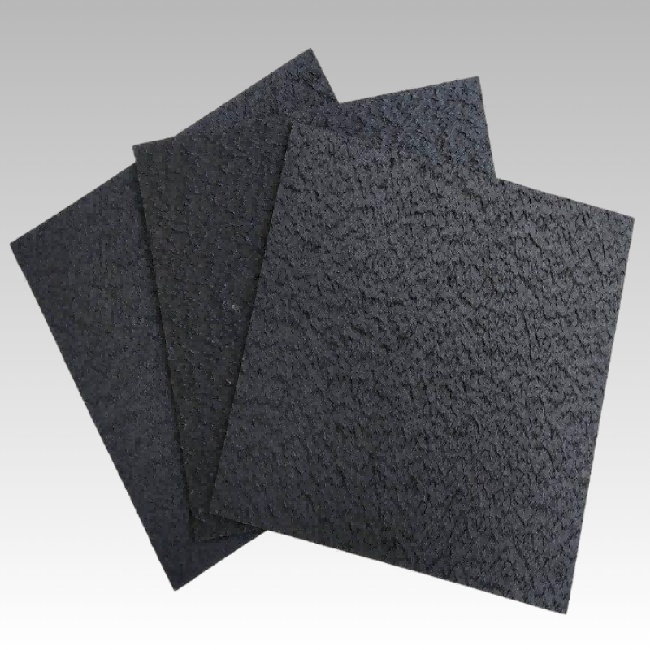

Product Introduction:

Geomembrane Material is a sophisticated, multi-layered engineered material created by the intentional combination of a geomembrane with one or more other geosynthetics. Unlike single-layer geomembranes that primarily provide an impermeable barrier, composite geomembranes are designed as integrated systems to address multiple geotechnical challenges simultaneously. The synergy between the layers results in a product whose overall performance is superior to the sum of its parts.

Core Components and Common Configurations:

The specific combination of materials is tailored to the project's needs. The most prevalent types include:

1.Geomembrane (GM) + Geotextile (GT): This is the most widespread configuration.

Function: The geomembrane (typically HDPE, LLDPE, PVC, or PP) provides the essential impermeable barrier. The geotextile (usually non-woven for its cushioning and drainage properties) acts as a protective cushion, a drainage medium, and a friction interface.

Bonding Methods: The layers are factory-laminated through needling (where barbed needles punch the geotextile fibers into the geomembrane), thermal bonding, or adhesive.

2.Geomembrane (GM) + Geonet (GN): This creates a high-performance drainage composite.

Function: The geomembrane acts as the barrier, while the geonet's rigid, open structure serves as a conveyance core for the rapid lateral flow of liquids (leachate, water) or gases (landfill gas, vapour).

Applications: Primarily used in landfill liner and cover systems for leachate collection and gas removal.

3.Geomembrane (GM) + Geosynthetic Clay Liner (GCL): This hybrid offers a powerful combination of a robust barrier with self-sealing capabilities.

![Geomembrane Material Geomembrane Material]()

Product Advantages

Composite geomembranes offer synergistic benefits that single-layer geomembranes cannot provide:

1.Synergistic Multi-Functionality:

This is the core advantage. A single, factory-integrated product delivers:

Hydraulic Barrier: From the geomembrane layer.

Protection and Cushioning: The geotextile layer distributes localized stresses and protects the geomembrane from puncture by sharp aggregates or uneven subgrades.

Drainage and Filtration: The geotextile or geonet layer allows for the controlled passage and lateral movement of fluids, relieving hydrostatic pressure.

Enhanced Interface Shear Strength: The textured surface of the geotextile provides a high-friction interface with soils and other geosynthetics, drastically improving the stability of slopes on landfill liners, embankments, and retaining walls.

2.Superior Installation Integrity and Quality Assurance:

3.Optimized Life-Cycle Cost:

While the initial unit cost may be higher than individual components, the composite leads to substantial overall savings. It reduces material handling, speeds up installation, minimizes the required quality control checks for multiple layers, and enhances long-term performance, reducing the risk of costly failures and repairs.

4.Increased Puncture and Chemical Resistance:

The protective geotextile layer significantly increases the effective puncture resistance of the underlying geomembrane, making it suitable for harsh environments like landfills and mining applications. The geomembrane layer itself is selected for its chemical resistance to the contained fluids (leachate, chemicals, etc.).

5.Dimensional Stability and Stress Absorption:

![Geomembrane Material Geomembrane Material]()

Product Parameters:

| Metric | ASTM | unit | Test value | Minimum test frequency |

| test method | 0.75 mm | 1.00 mm | 1.25 mm | 1.50 mm | 2.00 mm | 2.50mm | 3.00 mm |

| Minimum average thickness | D5199 | mm | 0.75 | 1 | 1.25 | 1.5 | 2 | 2.5 | 3 | Per volume |

| Minimum value (any one of 10) | -10% | -10% | -10% | -10% | -10% | -10% | -10% |

| minimum density | D 1505/D 792 | g/cm3 | 0.94 | 0.94 | 0.94 | 0.94 | 0.94 | 0.94 | 0.94 | 90,000 kg |

| Minimum average tensile performance (1) | D638 Type IV |

|

|

| Breakage strength, |

| N/mm | 20 | 27 | 33 | 40 | 53 | 67 | 80 | 9,000 kg |

| yield strength | N/mm | 11 | 15 | 18 | 22 | 29 | 37 | 44 |

| Strain extension, | % | 700 | 700 | 700 | 700 | 700 | 700 | 700 |

| yield extension | % | 12 | 12 | 12 | 12 | 12 | 12 | 12 |

| Minimum strength of right-angle tear | D 1004 | N | 93 | 125 | 156 | 187 | 249 | 311 | 374 | 20,000 kg |

| Minimum puncture strength | D4833 | N | 240 | 320 | 400 | 480 | 640 | 800 | 960 | 20,000 kg |

| Constant tensile load stress cracking (2) | D5397 | hour | 300 | 300 | 300 | 300 | 300 | 300 | 300 | Based on GRI GM-10 |

| Carbon black content | D 1603(3) | % | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 9,000 kg |

| Carbon black dispersion | D5596 |

| Note (4) | Note (4) | Note (4) | Note (4) | Note (4) | Note (4) | Note (4) | 20,000 kg |

| Oxygen induction time (OIT) (5) |

| 90,000 kg |

| (a) Standard OIT | D3895 | minute | 100 | 100 | 100 | 100 | 100 | 100 | 100 |

| (b) high-handed OIT | D5885 | minute | 400 | 400 | 400 | 400 | 400 | 400 | 400 |

| 85℃ Oven aging (minimum average) (5)(6) |

| Per formula |

| (A) Standard OIT is retained after 90 days | D 5721 | % | 55 | 55 | 55 | 55 | 55 | 55 | 55 |

| (B) High voltage OIT is retained for 90 days | D 3895 D5885 | % | 80 | 80 | 80 | 80 | 80 | 80 | 80 |

| Ultraviolet resistance (7) |

| Per formula |

| (a) standard OIT | D3895 |

| Note (8) 50 |

| (b) Retention of high pressure OIT after 1600 hours (9) | D5885 | % |

![Geomembrane Material Geomembrane Material]()

Product Applications:

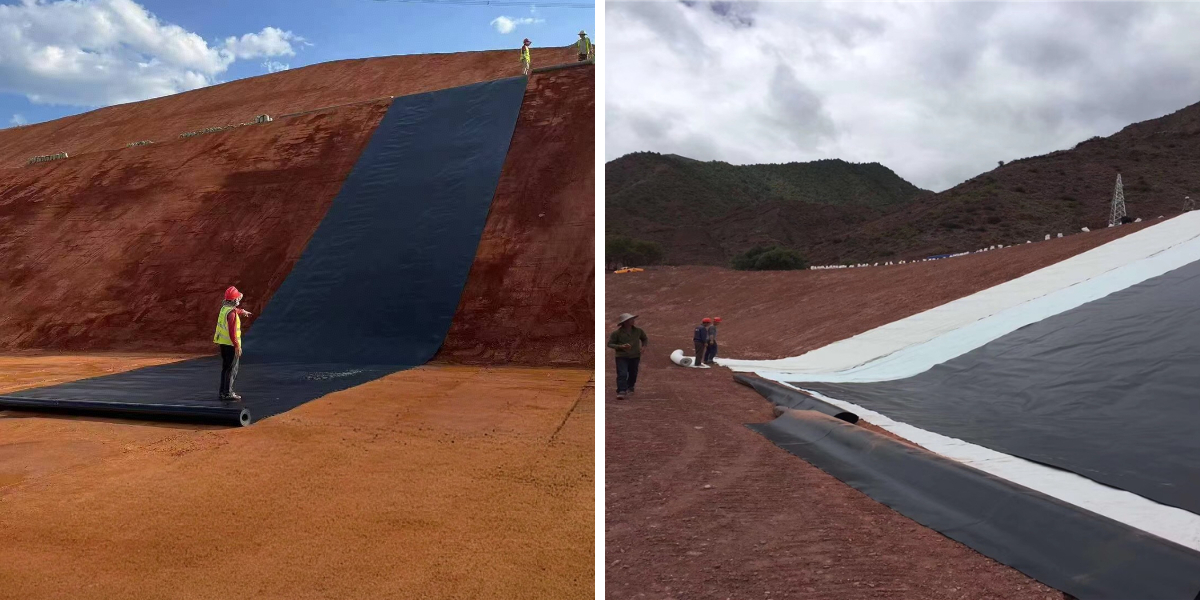

Composite geomembranes are essential in projects where a robust, multi-functional barrier system is required:

1.Environmental Containment (The Primary Market):

Modern Landfill Systems: Used as the primary composite liner (e.g., GM/GT over a compacted clay liner or GCL) and in the final cap system. They are critical for containing leachate and landfill gas, protecting groundwater resources.

Mining and Industrial Applications: Lining for tailings storage facilities (TSF), heap leach pads, and process water ponds. They contain toxic or acidic solutions, preventing catastrophic environmental contamination. The GM/GN composites are often used in leak detection layers beneath these facilities.

2.Water Resource Management:

Potable Water Reservoirs and Canals: The composite structure ensures zero seepage loss and protects the water quality from external contaminants. The geotextile side is placed against the soil to protect the geomembrane.

Aquaculture and Decorative Ponds: Provides a durable, long-lasting lining that is resistant to damage from wildlife and root penetration.

Stormwater Management Ponds: Used for temporary containment and treatment of runoff.

3.Civil and Geotechnical Engineering:

Tunnel and Underground Waterproofing: Serves as a continuous, puncture-resistant membrane behind concrete segmental linings, preventing groundwater infiltration into subway systems, road tunnels, and other underground structures.

Beneath Landscaped Areas and Hardscapes: Used as a root barrier and moisture control layer beneath plazas, green roofs, and artificial landscapes to protect the underlying structure from water damage and root penetration.

4.Transportation Infrastructure:

Beneath Road Embankments on Soft Soils: In some cases, a composite geomembrane can be used to separate subsoil from aggregate, prevent water ingress, and provide some reinforcement, improving the foundation's stability.

![Geomembrane Material Geomembrane Material]()

In summary, Composite Geomembranes represent a pinnacle of geosynthetic engineering. They are not merely materials but pre-fabricated, high-performance systems that deliver unparalleled reliability, efficiency, and protection in the world's most demanding containment and civil engineering challenges.