Typar Geotextile Fabric

1.High Tensile Strength and Modulus: The primary advantage is their exceptional strength-to-weight ratio. They can absorb and distribute tensile forces, thereby reinforcing the soil mass and preventing failure.

2.Filtration and Drainage: Their permeable nature allows water to flow through them while preventing the erosion of fine soil particles, thus facilitating proper drainage and reducing pore water pressure.

3.Cost-Effectiveness: They often reduce the need for importing high-quality fill material and decrease the required depth of aggregate, leading to substantial cost savings in earthworks.

4.Durability and Long-Term Performance: Made from robust polymers like polypropylene or polyester, they are resistant to biological degradation, chemicals, and UV radiation, ensuring a long design life.

Product Introduction:

A Reinforced Geotextile is a high-performance geosynthetic composite engineered to provide paramount tensile strength and structural reinforcement to soil, while simultaneously offering the classic functions of separation, filtration, and drainage. Think of it as the "rebar" within "soil concrete." It is a synergistic product that combines the best attributes of different materials: the high tensile strength and stiffness of a reinforcement component (like a geogrid or high-tenacity yarns) with the protective and hydraulic properties of a geotextile.

This combination is crucial because soil is strong in compression but weak in tension. By introducing a tensile element, reinforced geotextiles allow for the creation of a coherent, stabilized soil mass that can withstand significant stresses and deformations, enabling the construction of complex structures on challenging grounds.

Reinforced geotextiles offer a multitude of technical and economic benefits:

1. Enhanced Mechanical Properties:

Superior Tensile Strength & Stiffness: They exhibit a high tensile modulus at low strain, meaning they resist deformation effectively from the moment the load is applied. This is critical for maintaining the shape and integrity of structures like steep slopes and retaining walls.

Robust Puncture and Tear Resistance: The reinforcing component provides exceptional resistance to damage during installation and from sharp aggregates or irregular subgrades, ensuring long-term performance.

Improved Fatigue Resistance: They are designed to withstand cyclic loading (e.g., from repeated traffic on roads or railways) without significant degradation in their mechanical properties.

2. Advanced Geotechnical Functions:

Composite Action (Soil-Reinforcement Interaction): The key mechanism is the development of friction and interlock between the soil particles and the geotextile. This interaction transfers tensile forces from the soil into the reinforcement, creating a stable, reinforced mass.

Confinement: By wrapping the soil, the geotextile applies a confining pressure, which increases the shear strength of the soil according to the principles of soil mechanics (e.g., the Mohr-Coulomb failure criterion).

Accelerated Consolidation: When a nonwoven component is used, it provides a lateral drainage path, allowing pore water pressures from soft soils to dissipate quickly. This accelerates settlement during the construction phase, leading to faster gains in soil strength.

3. Economic and Construction Benefits:

Significant Cost Savings: They reduce the need for importing high-quality borrow materials and decrease the required depth of aggregate base courses. They can also eliminate the need for expensive deep foundations or pile-supported systems on soft soils.

Enables Construction on Marginal Sites: Projects on very soft clays, peat, or loose fills, which were once deemed unfeasible or prohibitively expensive, become viable.

Increased Construction Speed: The use of reinforced geotextiles simplifies construction logistics and often allows for the use of locally available fill materials, speeding up project timelines.

Predictable Performance and Reduced Long-Term Maintenance: By preventing subgrade contamination, rutting, and differential settlement, they ensure a more uniform and durable infrastructure with lower lifecycle costs.

Product Parameters:

project | metric | ||||||||||

Nominal strength/(kN/m) | |||||||||||

6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |||

1 | Longitudinal and transverse tensile strength / (kN/m) ≥ | 6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |

2 | Maximum elongation at maximum load in longitudinal and transverse directions/% | 30~80 | |||||||||

3 | CBR top penetration strength /kN ≥ | 0.9 | 1.6 | 1.9 | 2.9 | 3.9 | 5.3 | 6.4 | 7.9 | 8.5 | |

4 | Longitudinal and transverse tearing strength /kN | 0.15 | 0.22 | 0.29 | 0.43 | 0.57 | 0.71 | 0.83 | 1.1 | 1.25 | |

5 | Equivalent aperture O.90(O95)/mm | 0.05~0.30 | |||||||||

6 | Vertical permeability coefficient/(cm/s) | K× (10-¹~10-), where K=1.0~9.9 | |||||||||

7 | Width deviation rate /% ≥ | -0.5 | |||||||||

8 | Unit area mass deviation rate /% ≥ | -5 | |||||||||

9 | Thickness deviation rate /% ≥ | -10 | |||||||||

10 | Thickness coefficient of variation (CV)/% ≤ | 10 | |||||||||

11 | Dynamic perforation | Puncture hole diameter/mm ≤ | 37 | 33 | 27 | 20 | 17 | 14 | 11 | 9 | 7 |

12 | Longitudinal and transverse fracture strength (grab method)/kN ≥ | 0.3 | 0.5 | 0.7 | 1.1 | 1.4 | 1.9 | 2.4 | 3 | 3.5 | |

13 | Ultraviolet resistance (Xenon arc lamp method) | Longitudinal and transverse strength retention rate% ≥ | 70 | ||||||||

14 | Ultraviolet resistance (fluorescence UV lamp method) | Longitudinal and transverse strength retention rate% ≥ | 80 | ||||||||

Product Applications:

Reinforced geotextiles are critical in a wide range of civil engineering and construction projects:

1. Road and Railway Construction:

Unpaved Roads & Working Platforms: On soft subgrades, they create a stable platform for construction traffic, preventing the aggregate from punching down and the subgrade soil from pumping up. This is essential for temporary access roads and platforms for cranes and piling rigs.

Paved Road Base Reinforcement: Placed between the subgrade and base course, they extend the service life of asphalt pavements by reducing reflective cracking and limiting permanent deformation.

Railway Track Beds: They stabilize the ballast and sub-ballast layers, reducing track settlement and maintenance frequency, and improving track geometry.

2. Reinforced Soil Structures (RSS):

Reinforced Soil Slopes (RSS): Enable the construction of near-vertical to vertical slopes, maximizing land use in congested areas (e.g., highway embankments) with a smaller footprint than conventional sloped embankments.

Mechanically Stabilized Earth (MSE) Walls: This is a primary application. The reinforced geotextile layers are the "tie-backs" that hold the soil mass together, allowing for the construction of high, cost-effective retaining walls for bridges, highways, and waterfronts.

Embankments over Soft Foundations: They act as a basal reinforcement, distributing the load of a new embankment over a wider area, thus preventing bearing capacity failure and global instability.

3. Environmental and Hydraulic Applications:

Landfill Liners and Caps: They provide reinforcement over weak subgrades beneath composite liner systems. They also protect geomembranes from puncture. In final caps, they help stabilize the cover soil.

Coastal and Riverbank Protection: Placed beneath riprap (armor stone) or concrete block systems, they prevent the washout of underlying fine soil, enhancing the stability and longevity of the erosion protection system.

Reinforced Vegetated Walls: A sustainable application where the geotextile is used to create a stable structure that is then vegetated, providing an environmentally friendly and aesthetically pleasing slope or wall face.

4. Specialized Foundation Support:

Over Unstable Soils: For sites with very poor soil conditions (e.g., with a California Bearing Ratio (CBR) < 1), multiple layers of high-strength reinforced geotextiles can be used to create a stable "mattress" or "raft" that bridges local soft spots.

Common Types of Reinforced Geotextiles

Understanding the composition helps in selecting the right product:

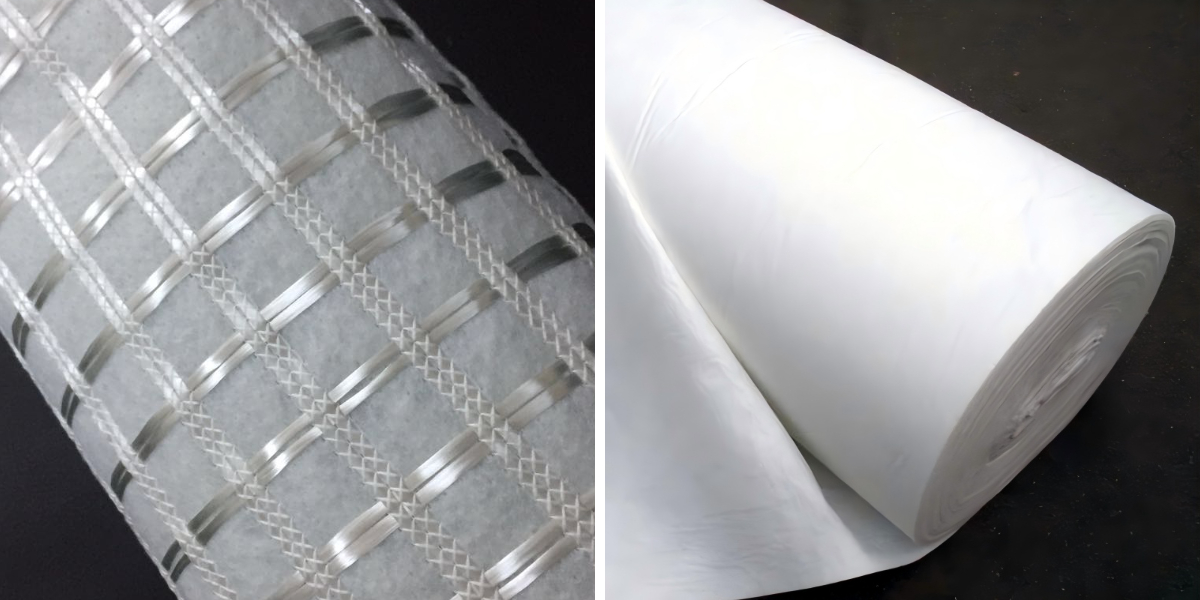

1.Nonwoven Geotextile + Geogrid Composite: A needle-punched nonwoven geotextile is laminated (often by heat or needle-punching) to a biaxial or uniaxial geogrid. This is one of the most common types, offering an excellent balance of separation, filtration, drainage, and reinforcement.

2.Woven Geotextile with High-Tenacity Yarns: These are woven from high-strength polyester or polypropylene tapes or filaments. They offer very high tensile strength and modulus but typically have lower filtration properties compared to nonwoven composites.

3.Woven-Nonwoven Composite: Combines the high strength of a woven fabric with the cushioning and filtration properties of a nonwoven geotextile, often used in critical applications requiring puncture protection for geomembranes alongside reinforcement.

In conclusion, reinforced geotextiles represent a paradigm shift in geotechnical engineering. They are not merely passive separators but are active, load-bearing elements that allow engineers to design and build safer, more economical, and more resilient infrastructure on a wide range of ground conditions. Their role in modern sustainable construction is indispensable.