Geotextile for French Drain

1.Strong integrity: providing a continuous and uniform force surface.

2.Quality controllable: industrialized production, stable and reliable performance.

3.Quick construction: greatly shorten the construction period.

4.High cost-effectiveness: saving material, transportation, and labor costs.

5.Good durability: prolongs the overall service life of the project.

6.Strong adaptability: able to adapt to complex terrain and large foundation deformations.

Product Introduction:

Geotextile for French Drain is a permeable synthetic fiber fabric specially adapted for the French Drain system. It is usually made of high molecular weight materials such as polypropylene (PP) and polyester (PET), and is produced through processes such as needle punching, weaving, or thermal bonding. Its core function is "selective penetration" - it can not only allow rainwater and groundwater in the soil to smoothly infiltrate the drainage pipes inside the blind ditch, but also accurately intercept solid particles such as sediment and gravel to avoid pipeline blockage; At the same time, it can also isolate the gravel drainage layer in the blind ditch from the surrounding native soil, preventing the mixing of different particle media from causing blockage of the drainage channel, and is a "filtering barrier" to ensure the long-term effective operation of the blind ditch.

Key features: Core performance advantages of geotextiles used in blind ditches

The geotextile used in blind ditches is not an ordinary fabric, and its performance needs to adapt to the complex environment of underground moisture, compression, and susceptibility to chemical erosion. The core characteristics can be summarized as "four highs and two strengths", and the specific manifestations and effects on blind ditches are as follows:

1. High permeability

The porosity of geotextile can usually reach 70% -90%, and the vertical permeability coefficient is generally ≥ 1 × 10 ⁻ cm/s (much higher than the permeability velocity of natural soil). This high permeability ensures that water in the soil can quickly penetrate the fabric into the blind ditch, avoiding water retention in the soil and reducing the damage of accumulated water to the foundation, vegetation, or facilities from the source.

2. High filtration performance

By precisely controlling the equivalent pore size of the fabric (O ₉₀, which means 90% of the pores are smaller than this diameter), geotextiles used in blind ditches can achieve the effect of "water passing through the soil": their equivalent pore size is usually between 0.1-0.5mm, which can be flexibly adjusted according to the size of surrounding soil particles, allowing only water molecules to pass through while intercepting sediment particles in the soil, completely avoiding pipeline failure due to blockage - blockage is the most common fault of blind ditches, and high filtration is the key to solving this problem.

3. High corrosion resistance

There are often acidic and alkaline substances (such as organic acids in soil and salts in groundwater) and microorganisms in the underground environment. Geotextiles used in blind ditches have excellent acid and alkali resistance (suitable for pH values ranging from 3-11), microbial erosion resistance, and will not degrade or be damaged due to long-term contact with corrosive substances. They can match the service life of blind ditch pipelines (usually 20-50 years).

4. High tensile strength

In blind ditch construction and later use, geotextile needs to withstand the tension caused by soil pressure, construction compaction, and foundation settlement. Its longitudinal and transverse tensile strength is generally ≥ 10kN/m, and its tear resistance strength is ≥ 0.5kN, which can effectively resist external pulling without damage, ensuring the integrity of the filtering structure.

5. Strong wear resistance

The surface of geotextile has undergone special wear-resistant treatment, making it less prone to scratches and holes when rubbed against gravel, drainage pipes, dragged or laid during construction; Even in contact with sharp stones, it can reduce the risk of damage and prevent mud and sand from seeping into the pipeline due to fabric damage.

6. Strong aging resistance

During the production process, anti ultraviolet (UV) agents and antioxidants are added. Even if the blind ditch is buried shallowly, exposed to a small amount of UV radiation, or exposed to high temperature and humidity underground for a long time, the geotextile is not prone to aging and cracking, and can maintain stable filtration and permeability performance for a long time.

Product Parameters:

project | metric | ||||||||||

Nominal strength/(kN/m) | |||||||||||

6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |||

1 | Longitudinal and transverse tensile strength / (kN/m) ≥ | 6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |

2 | Maximum elongation at maximum load in longitudinal and transverse directions/% | 30~80 | |||||||||

3 | CBR top penetration strength /kN ≥ | 0.9 | 1.6 | 1.9 | 2.9 | 3.9 | 5.3 | 6.4 | 7.9 | 8.5 | |

4 | Longitudinal and transverse tearing strength /kN | 0.15 | 0.22 | 0.29 | 0.43 | 0.57 | 0.71 | 0.83 | 1.1 | 1.25 | |

5 | Equivalent aperture O.90(O95)/mm | 0.05~0.30 | |||||||||

6 | Vertical permeability coefficient/(cm/s) | K× (10-¹~10-), where K=1.0~9.9 | |||||||||

7 | Width deviation rate /% ≥ | -0.5 | |||||||||

8 | Unit area mass deviation rate /% ≥ | -5 | |||||||||

9 | Thickness deviation rate /% ≥ | -10 | |||||||||

10 | Thickness coefficient of variation (CV)/% ≤ | 10 | |||||||||

11 | Dynamic perforation | Puncture hole diameter/mm ≤ | 37 | 33 | 27 | 20 | 17 | 14 | 11 | 9 | 7 |

12 | Longitudinal and transverse fracture strength (grab method)/kN ≥ | 0.3 | 0.5 | 0.7 | 1.1 | 1.4 | 1.9 | 2.4 | 3 | 3.5 | |

13 | Ultraviolet resistance (Xenon arc lamp method) | Longitudinal and transverse strength retention rate% ≥ | 70 | ||||||||

14 | Ultraviolet resistance (fluorescence UV lamp method) | Longitudinal and transverse strength retention rate% ≥ | 80 | ||||||||

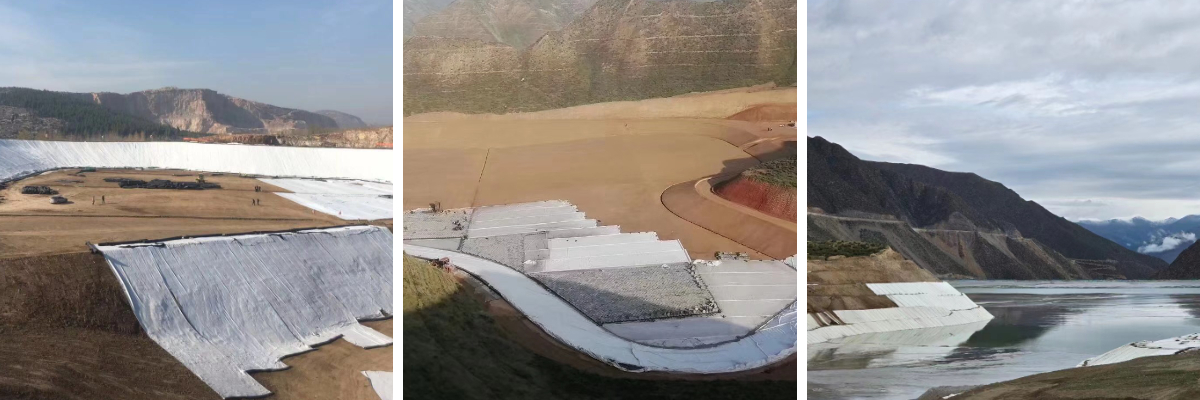

Product Applications:

1. In the field of architecture and municipal engineering

House foundation drainage: When laying blind ditches around the foundation of a house in low-lying areas or clay soil, geotextiles can intercept soil particles, prevent pipe blockage, and prevent rainwater from seeping into the foundation, causing wall moisture regain, foundation settlement, or cracking;

Basement/garage anti-seepage and drainage: Geotextile is laid in the blind ditch outside the basement to prevent external soil and sediment from entering the drainage pipeline, ensuring timely drainage of rainwater and groundwater, and avoiding basement seepage and wall mold;

Road and parking lot base drainage: In the blind ditches of the base layer of highways, municipal roads, or parking lots, geotextiles can quickly drain rainwater that seeps into the base layer, preventing softening of the roadbed, cracking or bulging of the road surface, and extending the service life of the road.

2. Landscape greening and landscaping field

Lawn and flower bed drainage: Lawn and flower beds made of clay or compacted soil are prone to water accumulation. Blind ditches combined with geotextiles can quickly drain excess water, prevent lawn root rot and flower withering, and maintain healthy vegetation growth;

Surrounding drainage of artificial lakes/water features: In blind ditches around artificial lakes and landscape water pools, geotextiles can isolate soil and gravel layers to prevent sedimentation and blockage of pipelines. At the same time, excess groundwater in the surrounding areas can be drained to prevent soil subsidence and tilt of landscape facilities;

Golf course/sports field drainage: This type of frequently used field needs to keep the soil moderately dry and flat. Using geotextile for blind ditches can ensure drainage efficiency and avoid the field becoming muddy due to accumulated water, which affects the user experience.

3. In the field of agriculture and ecological engineering

Farmland drainage: Blind ditches are laid in low-lying farmland, rice paddies, or easily flooded farmland. Geotextiles can intercept sediment in the fields to ensure rapid drainage of rainwater, prevent crop waterlogging, and increase crop yields;

Slope protection and drainage: In the blind ditch system of highway, railway slope or mountain slope protection, geotextile can filter the sediment carried by rainwater, avoid blockage of drainage channels, and protect the slope soil from loss, enhancing slope stability;

Wetland restoration project: In the drainage system of artificial wetlands, geotextiles can control the rate of water infiltration, balance the water level inside the wetland, and prevent external soil particles from entering the wetland, maintaining the stability of the wetland ecological environment.

4. Industrial site field

Factory yard drainage: Open air yards for coal, ore, building materials, etc. are prone to clumping due to moisture caused by rainwater. Using geotextile in blind ditches can quickly drain the accumulated water below the yard, reduce material loss, and ensure the efficiency of yard operations;

Sewage treatment plant supporting drainage: Geotextile can prevent soil and sediment from entering the drainage pipeline around the treatment tank and sedimentation tank in the blind ditch of the sewage treatment plant, and also prevent sewage from infiltrating underground and polluting the soil, ensuring environmental compliance.

In summary, the use of geotextile in blind ditches is the "core guarantee" of the French Drain system - without suitable geotextile, blind ditches will quickly lose their effectiveness due to blockage. Only by correctly understanding its definition, mastering its core characteristics, accurately matching its application scenarios, and doing a good job in selection and installation, can blind ditches play a long-term stable drainage role and effectively solve various problems caused by underground water accumulation.