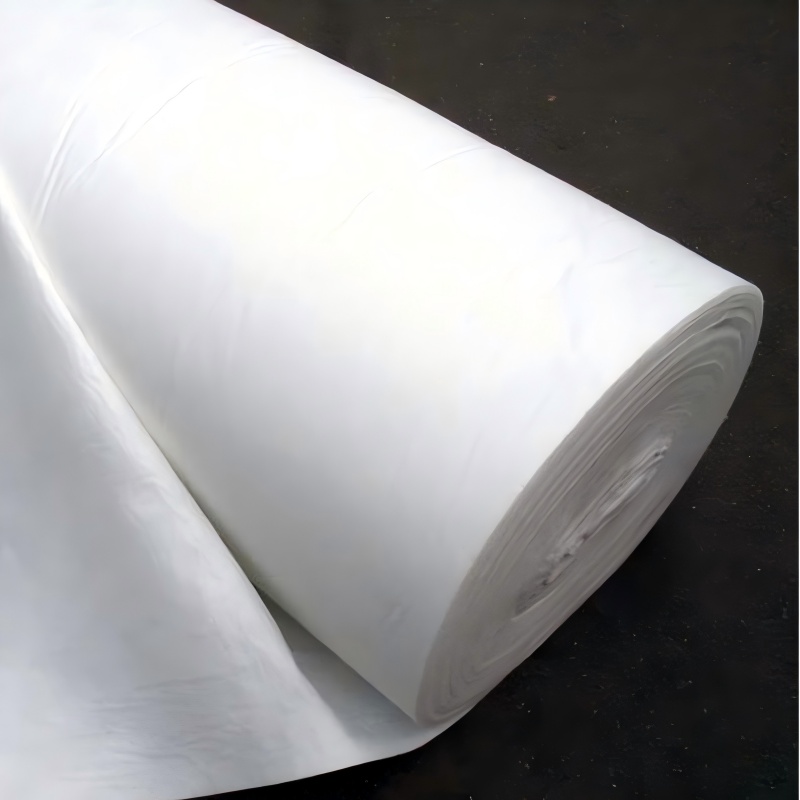

Protection Geotextile

1. Performance consistency: Industrialized production, stable and controllable quality, uniform and consistent performance, avoiding the variability and uncertainty of natural materials.

2. Simplify construction: Laying a layer of geotextile can often replace traditional complex processes such as excavation, replacement, and laying sand and gravel filter layers, greatly simplifying the construction process.

3. Strong adaptability: It has good flexibility, can adapt to uneven foundation deformation, and has a tight bond with the soil.

4. Extend the service life of the project: By effectively filtering, draining, and reinforcing, the long-term stability and service life of structures such as roadbeds, embankments, and retaining walls have been significantly improved.

Product Introduction:

Protection Geotextile is a permeable geosynthetic material made from high molecular weight polymers (such as polypropylene, polyester, polyethylene, etc.) through processes such as spinning, needle punching, weaving, thermal bonding, or chemical bonding. It plays the role of an "engineering fabric" in fields such as civil engineering, water conservancy engineering, and transportation engineering, mainly used to improve soil performance and enhance the stability of engineering structures. It is an indispensable key material in modern infrastructure construction.

Definition of Geotextile

From the perspective of material essence and functional positioning, geotextile can be defined as a permeable planar structural material made from synthetic fibers or natural fibers (mainly synthetic fibers in modern engineering) through specific processing techniques, with functions such as filtration, drainage, isolation, reinforcement, and protection.

Its core attributes need to meet two key conditions:

Permeability: Different from plastic film (geomembrane), geotextile has a certain porosity (usually 30% -90%), allowing water or gas to penetrate inside or along the surface of the material, which is the basis for achieving filtration and drainage functions;

Engineering applicability: It is necessary to have sufficient mechanical strength (tensile strength, tear resistance, puncture resistance) and environmental aging resistance (UV resistance, acid and alkali resistance, microbial erosion resistance) to adapt to the long-term effects of complex engineering environments such as soil, water, and climate.

Core characteristics of geotextile

The characteristics of geotextiles are determined by their raw material properties and processing techniques, which can be summarized into the following six points:

1. Excellent mechanical properties

High tensile strength: Synthetic fibers (such as polyester and polypropylene) have several times the tensile strength of cotton. After processing, the longitudinal/transverse tensile strength of geotextiles can reach 10-100kN/m (depending on specifications), which can effectively resist the tensile force caused by soil deformation;

Strong tear and puncture resistance: Needling or weaving processes intertwine or interweave fibers to form a tight structure that can resist mechanical friction and soil particle punctures during construction, avoiding material damage;

Stable elastic modulus: Within the range of stress, there is a good linear relationship between deformation and tension, and there will be no significant deformation due to short-term load fluctuations, ensuring the stability of the engineering structure.

2. Controllable permeability

The permeability of geotextiles is determined by porosity and pore size, and can be customized according to demand through process adjustments:

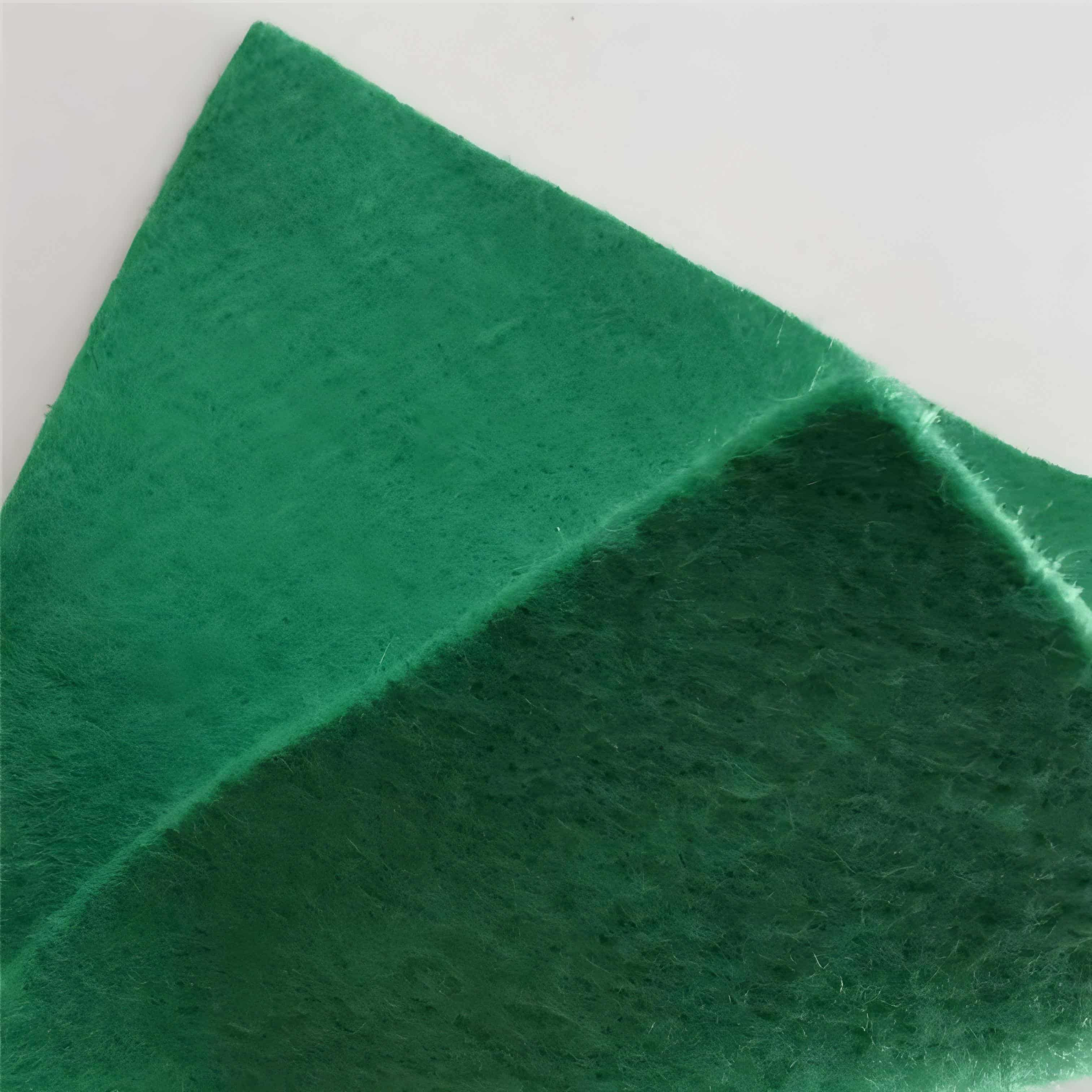

The porosity of needle punched non-woven geotextiles is usually 70% -90%, and the equivalent pore size (O95) is mostly between 0.05-0.5mm, suitable for filtration (preventing soil particle loss and allowing water infiltration);

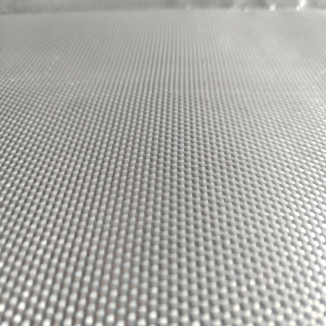

The porosity of woven geotextile is about 30% -60%, with larger pore sizes, making it more suitable for drainage (accelerating water discharge and reducing soil moisture content).

3. Excellent resistance to environmental aging

Chemical corrosion resistance: It has good tolerance to acids and bases (such as acidic substances in soil and industrial wastewater), salts (such as seawater salts in coastal areas), and will not degrade or experience a sudden drop in strength due to chemical reactions;

Anti UV aging: Some geotextiles are added with anti UV agents, which can be used for a long time in outdoor environments (such as roadbeds and slope protection) (usually designed for a lifespan of 5-20 years) to avoid fiber brittleness caused by sunlight exposure;

Resistant to microbial erosion: Synthetic fibers are not decomposed by bacteria or fungi in the soil, and will not rot like natural fibers (such as burlap) due to microbial action.

4. Lightweight and easy to construct

Lightweight: The unit area weight (gram weight) of conventional geotextile is 100-800g/㎡, and the weight per square meter is only 1/10-1/5 of the same thickness of soil. It is easy to transport and lay, and can greatly reduce construction intensity;

Good flexibility: able to adapt to irregular terrain of soil (such as undulating slopes, sunken foundations), closely adhere to the soil surface, and avoid gaps caused by terrain differences;

Convenient splicing: It can be quickly spliced through methods such as hot bonding, seam joining, and adhesive bonding, with a splicing strength of over 80% of the base material strength, meeting the continuous laying needs of large-scale projects.

5. Environmental friendliness

Raw material environmental protection: Mainstream geotextiles use recyclable polymer materials such as polypropylene and polyester, and there are no toxic or harmful substance emissions during the production process;

Recyclable: After the completion of the project, some geotextiles can be recycled and reprocessed to reduce construction waste; Even if buried, synthetic fibers will not release harmful substances and have minimal impact on the soil environment.

6. Multi functional integration

A single geotextile can have multiple functions simultaneously, such as: needle punched non-woven geotextile can filter soil particles (filtering function), separate different soil layers (isolation function), and assist in draining soil moisture (drainage function), reducing the types and quantities of materials used in engineering.

Product Parameters:

project | metric | ||||||||||

Nominal strength/(kN/m) | |||||||||||

6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |||

1 | Longitudinal and transverse tensile strength / (kN/m) ≥ | 6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |

2 | Maximum elongation at maximum load in longitudinal and transverse directions/% | 30~80 | |||||||||

3 | CBR top penetration strength /kN ≥ | 0.9 | 1.6 | 1.9 | 2.9 | 3.9 | 5.3 | 6.4 | 7.9 | 8.5 | |

4 | Longitudinal and transverse tearing strength /kN | 0.15 | 0.22 | 0.29 | 0.43 | 0.57 | 0.71 | 0.83 | 1.1 | 1.25 | |

5 | Equivalent aperture O.90(O95)/mm | 0.05~0.30 | |||||||||

6 | Vertical permeability coefficient/(cm/s) | K× (10-¹~10-), where K=1.0~9.9 | |||||||||

7 | Width deviation rate /% ≥ | -0.5 | |||||||||

8 | Unit area mass deviation rate /% ≥ | -5 | |||||||||

9 | Thickness deviation rate /% ≥ | -10 | |||||||||

10 | Thickness coefficient of variation (CV)/% ≤ | 10 | |||||||||

11 | Dynamic perforation | Puncture hole diameter/mm ≤ | 37 | 33 | 27 | 20 | 17 | 14 | 11 | 9 | 7 |

12 | Longitudinal and transverse fracture strength (grab method)/kN ≥ | 0.3 | 0.5 | 0.7 | 1.1 | 1.4 | 1.9 | 2.4 | 3 | 3.5 | |

13 | Ultraviolet resistance (Xenon arc lamp method) | Longitudinal and transverse strength retention rate% ≥ | 70 | ||||||||

14 | Ultraviolet resistance (fluorescence UV lamp method) | Longitudinal and transverse strength retention rate% ≥ | 80 | ||||||||

Product Applications:

1. Construction of highways and railways

Isolation and reinforcement: laid between soft soil foundation and roadbed stone materials to prevent soft soil from surging and mixing with stone materials, while dispersing wheel loads, improving roadbed bearing capacity, and preventing pavement cracking and settlement.

Drainage: Set up drainage ditches or layers in the roadbed to guide the discharge of water and keep the roadbed dry.

2. Water conservancy engineering (dams, rivers, coasts)

Anti filter layer: used for the upstream and downstream surfaces of earth and rock dams and embankments to prevent soil particles from being carried away by water flow (piping), while ensuring smooth discharge of seepage. It is the core material for ensuring dam safety.

Anti erosion protection: used for riverbanks, coasts, reservoir slopes, underneath throwing stones or concrete blocks to prevent water flow from eroding the foundation soil.

Drainage: used to construct vertical or horizontal drainage systems behind dam bodies and retaining walls.

3. Environmental engineering (landfill site)

Protective layer: laid above and below the anti-seepage geomembrane to protect it from being pierced by sharp objects.

Leachate collection and drainage layer: In conjunction with geonets, it is used to collect and guide the leachate generated by garbage.

Filter layer: prevents waste particles from blocking drainage channels around the drainage system.

4. Municipal and Construction Engineering

Foundation drainage: The underground drainage around the foundation of a building.

Roof garden drainage: used for roof greening systems, providing drainage and filtration functions.

Basement moisture prevention: used in backfill soil for exterior walls to guide water flow towards the drainage system.

5. Other applications

Tunnel engineering: used for drainage behind the lining.

Airports and ports: Ground reinforcement and isolation of runways and yards.

Agriculture: Used for anti-seepage and slope protection of reservoirs and irrigation channels.

Ecological slope protection: In conjunction with three-dimensional vegetation networks, carry out slope greening and soil and water conservation.

In summary, although geotextile may not be attractive, it is an indispensable "multifunctional material" in modern geotechnical engineering. It has solved a large number of engineering problems that are difficult to handle with traditional technology in an economical, efficient, and reliable way through scientific design and application, and is an important technological progress in the field of engineering construction.