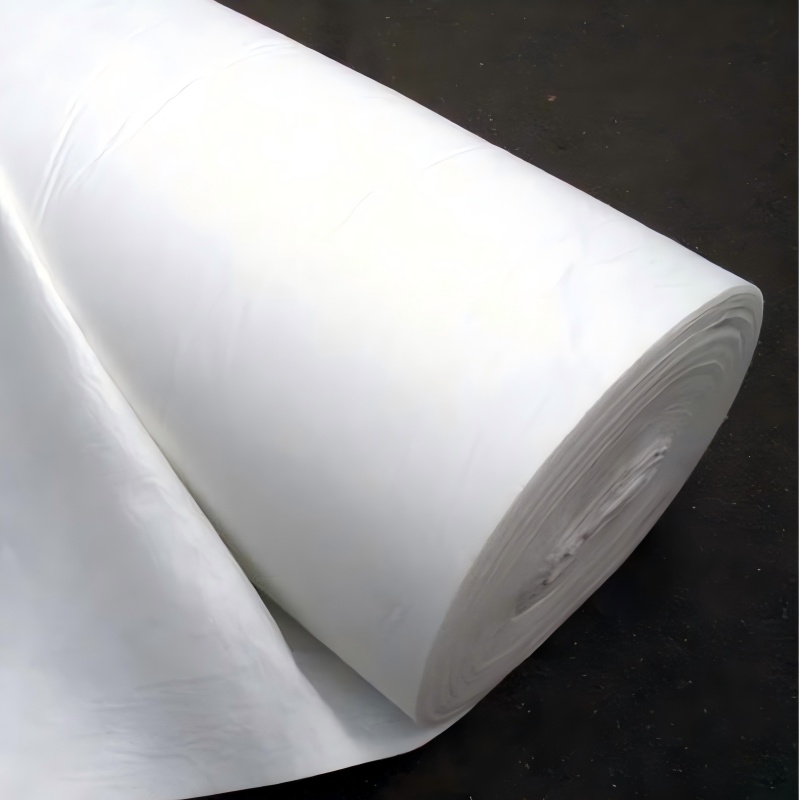

Driveway Stabilization Fabric

1. Soil consolidation and anti settlement: Enhance the overall integrity of the lane base, prevent soil subsidence, and avoid deformation and cracking of the gravel or asphalt layer.

2. Filter and drain moisture: quickly drain rainwater, prevent water accumulation from softening the base layer, and reduce lane mud and potholes.

3. Durable and resistant to rolling: resistant to vehicle crushing and wear, able to withstand outdoor sun and rain, and extending the service life of the lane.

4. Easy to lay and labor-saving: The quality is easy to cut, fits the ground terrain, does not require large equipment, and has high construction efficiency.

Products Introduction:

Driveway Stabilization Fabric is a functional geosynthetic material specially designed to improve the structural stability of the driveway. It is made of polypropylene (PP) or polyester (PET) filaments through needle punched non-woven or woven processes. Some products are anti-wear and anti-aging. Its core function is to be laid between the base layer (such as soil, sand and gravel layer) and the surface layer (such as gravel, asphalt, concrete) of the lane, and to solve the problems of sinking, deformation, cracking, etc. caused by soft base layer, soil erosion, and water accumulation erosion of the lane through the triple functions of "reinforcement and soil stabilization, filtering and moisture prevention, and isolation and protection", extending the service life of the lane and reducing maintenance costs.

The core advantage of this product compared to ordinary geotextiles lies in its strengthening of "load-bearing capacity" and "durability". It can adapt to different load scenarios such as private cars and trucks, and is widely used in residential private lanes, commercial parking lot lanes, rural roads, and other scenarios. It is a key supporting material for lane construction and renovation.

Product Features:

1. High strength reinforcement to prevent sinking and deformation

Adopting a high-strength fiber interwoven structure, the longitudinal/transverse tensile strength can reach 15-40kN/m, and the tear resistance strength is ≥ 3kN. After laying, it forms a "composite load-bearing system" with the lane base, which can effectively disperse vehicle loads (especially heavy vehicles such as trucks and SUVs), enhance the shear resistance of the base soil, prevent local subsidence of the soil due to compaction, and avoid the sinking of the surface layer (such as gravel particles and asphalt layer) to form potholes and ruts, significantly improving the flatness and bearing capacity of the lane.

2. Dual effect filtration and drainage, ensuring stable protection of the base layer

The fabric pores are scientifically designed (pore size 0.1-0.2mm), with both "filtering" and "drainage" functions: on the one hand, they intercept fine particles in the base soil, preventing them from penetrating into the surface layer with rainwater or vehicle compaction, avoiding blockage of gravel gaps and sanding of asphalt layers; On the other hand, it can quickly divert the accumulated water in the lane (permeability coefficient ≥ 1 × 10 ⁻ cm/s), prevent moisture from staying at the base and softening the soil, reduce the risk of structural instability caused by water erosion in the lane, especially suitable for areas with frequent rainfall or high groundwater levels.

3. Weather resistant and wear-resistant, long-lasting and durable

The surface has undergone special wear-resistant treatment, which can withstand long-term friction and sharp stone scratching of vehicle tires, and is not easily damaged; At the same time, the anti ultraviolet agent and anti-aging component are added, which can be used stably in outdoor sun and rain, high and low temperature (-30 ℃ to 70 ℃) environment, with a service life of 8-15 years, much higher than ordinary geotextiles, and reduce the maintenance cost of frequent lane renovation.

4. Easy to install and adapt, reducing construction costs

The texture is flexible (thickness 2-4mm), lightweight (200-400g/m ²), and can be flexibly cut according to the shape of the lane (straight, curved, broken line), closely fitting the undulating surface of the base layer, without blind spots for laying; No specialized large-scale equipment is required for laying, and manual overlap (overlap width ≥ 15cm) can be completed. It is compatible with conventional lane construction processes such as gravel paving and asphalt paving, and the construction efficiency is 40% higher than traditional sand and gravel reinforcement layers, with a comprehensive cost reduction of 15% -20%.

Product Parameters:

project | metric | ||||||||||

Nominal strength/(kN/m) | |||||||||||

6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |||

1 | Longitudinal and transverse tensile strength / (kN/m) ≥ | 6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |

2 | Maximum elongation at maximum load in longitudinal and transverse directions/% | 30~80 | |||||||||

3 | CBR top penetration strength /kN ≥ | 0.9 | 1.6 | 1.9 | 2.9 | 3.9 | 5.3 | 6.4 | 7.9 | 8.5 | |

4 | Longitudinal and transverse tearing strength /kN | 0.15 | 0.22 | 0.29 | 0.43 | 0.57 | 0.71 | 0.83 | 1.1 | 1.25 | |

5 | Equivalent aperture O.90(O95)/mm | 0.05~0.30 | |||||||||

6 | Vertical permeability coefficient/(cm/s) | K× (10-¹~10-), where K=1.0~9.9 | |||||||||

7 | Width deviation rate /% ≥ | -0.5 | |||||||||

8 | Unit area mass deviation rate /% ≥ | -5 | |||||||||

9 | Thickness deviation rate /% ≥ | -10 | |||||||||

10 | Thickness coefficient of variation (CV)/% ≤ | 10 | |||||||||

11 | Dynamic perforation | Puncture hole diameter/mm ≤ | 37 | 33 | 27 | 20 | 17 | 14 | 11 | 9 | 7 |

12 | Longitudinal and transverse fracture strength (grab method)/kN ≥ | 0.3 | 0.5 | 0.7 | 1.1 | 1.4 | 1.9 | 2.4 | 3 | 3.5 | |

13 | Ultraviolet resistance (Xenon arc lamp method) | Longitudinal and transverse strength retention rate% ≥ | 70 | ||||||||

14 | Ultraviolet resistance (fluorescence UV lamp method) | Longitudinal and transverse strength retention rate% ≥ | 80 | ||||||||

Product Applications:

1. Residential Gravel Lane

In the construction of residential private gravel lanes, they are laid between the soil base layer and the gravel layer, and reinforced to prevent soil subsidence and prevent gravel particles from becoming lower and looser due to crushing and embedding in the soil; Simultaneously filtering fine soil particles to prevent blockage of gravel gaps, maintaining lane permeability, reducing mud problems on rainy days, and adapting to daily driving scenarios for private cars.

2. Renovation of asphalt/concrete lanes

Used for the renovation of old asphalt or concrete lanes, laid between the base layer of the old lane and the new surface layer, to isolate loose particles and cracks in the old base layer and prevent reflection cracks from propagating to the new surface layer; At the same time, it enhances the overall integrity of the base layer, disperses vehicle loads, avoids cracking and sinking of the new surface layer due to the softness of the base layer, and extends the service life of the renovated lane.

3. Commercial parking lot lanes

Laying in commercial parking lots such as shopping malls and industrial parks, especially in truck lanes, selecting high-strength models (tensile strength ≥ 30kN/m) to cope with high-frequency loads from logistics trucks, forklifts, and other heavy vehicles. Through reinforcement and filtering functions, the base layer of the lane is prevented from long-term compression and sinking, reducing the frequency of surface damage and lowering the maintenance costs of the parking lot.

4. Rural road lanes

Used in hardened (paved with gravel or simple asphalt) lanes on rural dirt roads, laid between the soil base layer and the hardened surface layer to resist the rolling of agricultural machinery (tractors, harvesters) and prevent lane deformation caused by soil erosion; At the same time, it is necessary to divert the accumulated water during the rainy season, avoid muddy dirt roads that affect traffic, and adapt to the low maintenance and high durability needs of rural roads.

5. Slope lane

Used for lanes with slopes (slope ≤ 30 °) in residential areas, villas, etc., the reinforcement function is used to enhance the skid resistance of the base layer and prevent the overall downward sliding of the lane; At the same time, it filters soil particles to avoid the erosion of the base caused by rainwater, ensuring the long-term stability and traffic safety of the sloping lane.

Driveway Stabilization Fabric focuses on the core requirements of "stability, durability, and low cost" for lanes, with the core advantages of "high-strength reinforcement to prevent sinking, dual effect filter and drainage base layer, weather resistance, wear resistance, long service life, easy paving and adaptation, and cost saving", providing targeted stability solutions for various lane scenarios. Whether it is the foundation reinforcement of newly built gravel lanes, the renovation and maintenance of old lanes, or the heavy load requirements of commercial scenarios, scientific performance design can significantly improve the stability of lane structures, extend their service life, and reduce later maintenance investment.

This product combines functionality and economy, solving the pain points of traditional lanes that are prone to sinking, damage, and difficult maintenance. It also reduces overall costs through convenient construction and long-term durability, making it an ideal material for modern lane construction to achieve high cost-effectiveness and long-term stability. It provides reliable guarantees for lane safety and experience in different scenarios such as homes, businesses, and rural areas.