Geo Fabric Cloth

1. High strength and toughness: Made of high-quality materials, it maintains strong tensile strength and elongation in both dry and wet states, which can enhance the bearing capacity of the roadbed and reduce road deformation and settlement.

2. Outstanding corrosion resistance: able to withstand environments of different acidity and alkalinity, stable for a long time under complex chemical conditions, suitable for engineering in various harsh scenarios.

3. Good permeability: The fiber gap design achieves dual functions of water seepage and sand interception, ensuring the stability of water and soil engineering and preventing soil erosion.

4. There are advantages in construction and cost: the quality is soft and easy to construct, shortening the construction period and reducing labor costs; Stable performance reduces post maintenance and has high comprehensive benefits.

Products Introduction:

Geo Fabric Cloth is a new type of engineering material made from high-quality plastic fibers as the core material, processed through special techniques such as needle punching and weaving. The production process strictly controls the fiber ratio and molding process, which not only retains the strength advantage of the material itself, but also endows the product with good flexibility. This material combines multiple practical properties such as strength, flexibility, corrosion resistance, and permeability, and can easily meet the complex needs of different engineering scenarios such as roads, water conservancy, and environmental protection. It is one of the core materials in modern civil engineering to enhance structural stability and ensure engineering quality.

Product Features:

1. Combining strength and toughness: Made of polymer fibers, it has been tested to have a tensile strength of over 20kN/m, a fracture elongation rate of 20% -50%, and almost no performance degradation in dry or humid environments. This characteristic enables it to effectively disperse structural stress and enhance the load-bearing capacity of the foundation structure, making it less prone to fracture even under long-term heavy pressure.

2. Excellent corrosion resistance: after special anti-aging treatment, it has good resistance to acid and alkaline soil and water within the pH range of 3-11. In environments containing chemical pollutants, it can maintain structural integrity for more than 5 years, with a performance degradation rate of less than 10%, and can adapt to long-term use requirements in various complex chemical scenarios.

3. Permeability adaptation engineering requirements: Through precise fiber gap design, the permeability rate can reach 10-100m/d. While achieving efficient water infiltration, it can intercept soil particles larger than 0.05mm, perfectly balancing drainage and soil stabilization requirements, and avoiding structural instability caused by water flow erosion.

4. Significant construction and cost advantages: The weight of a single roll is only 20-50kg, the texture is light and soft, and it can be laid manually. The laying time per square meter does not exceed 3 minutes, which can greatly shorten the construction period and reduce labor costs. At the same time, due to stable performance, it can reduce maintenance investment by more than 30% in the later stage, and the overall cost is lower from the perspective of the entire project cycle.

Product Parameters:

project | metric | ||||||||||

Nominal strength/(kN/m) | |||||||||||

6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |||

1 | Longitudinal and transverse tensile strength / (kN/m) ≥ | 6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |

2 | Maximum elongation at maximum load in longitudinal and transverse directions/% | 30~80 | |||||||||

3 | CBR top penetration strength /kN ≥ | 0.9 | 1.6 | 1.9 | 2.9 | 3.9 | 5.3 | 6.4 | 7.9 | 8.5 | |

4 | Longitudinal and transverse tearing strength /kN | 0.15 | 0.22 | 0.29 | 0.43 | 0.57 | 0.71 | 0.83 | 1.1 | 1.25 | |

5 | Equivalent aperture O.90(O95)/mm | 0.05~0.30 | |||||||||

6 | Vertical permeability coefficient/(cm/s) | K× (10-¹~10-), where K=1.0~9.9 | |||||||||

7 | Width deviation rate /% ≥ | -0.5 | |||||||||

8 | Unit area mass deviation rate /% ≥ | -5 | |||||||||

9 | Thickness deviation rate /% ≥ | -10 | |||||||||

10 | Thickness coefficient of variation (CV)/% ≤ | 10 | |||||||||

11 | Dynamic perforation | Puncture hole diameter/mm ≤ | 37 | 33 | 27 | 20 | 17 | 14 | 11 | 9 | 7 |

12 | Longitudinal and transverse fracture strength (grab method)/kN ≥ | 0.3 | 0.5 | 0.7 | 1.1 | 1.4 | 1.9 | 2.4 | 3 | 3.5 | |

13 | Ultraviolet resistance (Xenon arc lamp method) | Longitudinal and transverse strength retention rate% ≥ | 70 | ||||||||

14 | Ultraviolet resistance (fluorescence UV lamp method) | Longitudinal and transverse strength retention rate% ≥ | 80 | ||||||||

Product Applications:

1. Road and railway engineering: Laying between the subgrade base and surface layer can disperse the pressure of vehicle loads on the subgrade and reduce problems such as cracking and settlement caused by long-term rolling of the pavement. Actual application data shows that roads using this geotextile can extend their service life by 5-8 years, especially suitable for heavy-duty traffic sections and soft soil foundation areas.

2. Water conservancy and dam engineering: used for structures such as anti-seepage layer and channel lining on the upstream face of dams. It can not only divert seepage water through permeability performance, reduce dam water pressure, but also resist water erosion with corrosion resistance. In small and medium-sized dam projects, the risk of dam leakage can be reduced by more than 30%, ensuring the long-term stable operation of water conservancy facilities.

3. Environmental Protection and Landfill Engineering: Used as an intermediate isolation layer in the anti-seepage system of landfills, it can prevent harmful substances in the leachate from penetrating into the soil and groundwater. Simultaneously resistant to acid and alkali corrosion and microbial erosion in landfills, enhancing the safety of environmental engineering and meeting strict standards for environmental engineering.

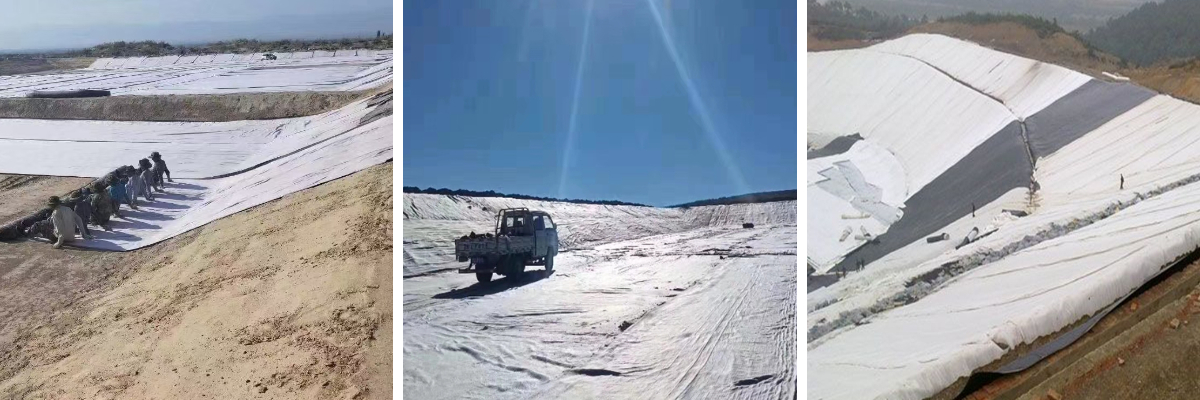

4. Geotechnical and infrastructure engineering: In slope reinforcement projects, laying on the surface of the slope and fixing it with anchor rods can prevent slope collapse through soil stabilization; In foundation treatment, it can reduce the settlement of the foundation, improve the bearing capacity of the foundation, and is suitable for infrastructure projects such as building foundations and large venue foundations.

Geo Fabric Cloth is based on high-quality plastic fibers and integrates core features such as high strength, corrosion resistance, and permeability through advanced technology. It has demonstrated an irreplaceable role in various engineering fields such as roads, water conservancy, environmental protection, and geotechnical engineering. From a performance perspective, it can adapt to harsh tests in different environments, providing stable mechanical support and protective effects for engineering structures; In terms of application value, it can not only improve the stability and durability of the project, reduce later maintenance costs, but also shorten the construction period through efficient construction, saving time and economic costs for the project. Whether facing road construction on soft soil foundations or complex acid alkali landfill projects, this geotextile can become the preferred material in engineering construction due to its balanced performance and reliable performance. In the future, with the development of engineering technology, its potential for application in more new engineering scenarios will be further released, continuously providing efficient and economical solutions for the field of civil engineering.