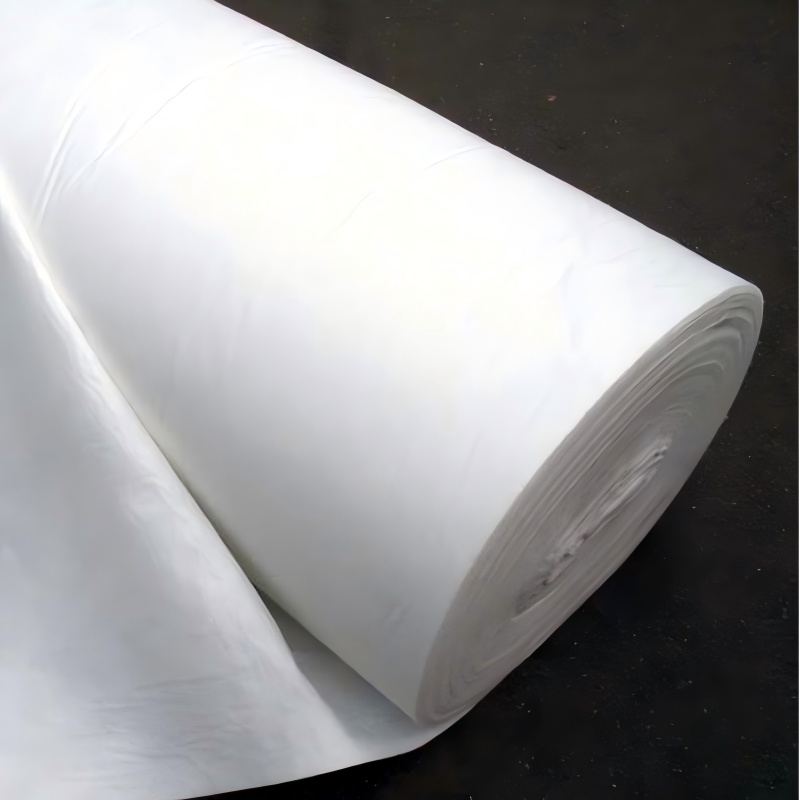

Stabilization Geotextile Fabric

1.Strong reinforcement: Enhance soil strength, disperse loads, reduce settlement deformation, and stabilize structures.

2.Environmental resistance: resistant to acid and alkali aging, suitable for use in damp saline alkali land, permeable, waterproof and sedimentation prone

3.Easy construction: The material is light and soft, easy to cut and lay, without the need for complex equipment, saving time.

4.Low cost: cheaper than reinforced concrete, reduces maintenance costs, and has a longer project lifespan.

Product Introduction

Stabilization Geotextile Fabric are common materials used to enhance soil stability, widely applied in projects like highways and water conservancy. Below is a simple explanation from three aspects:

I. Basic Properties

Core Positioning: A synthetic material that "strengthens" soil, compensating for the poor tensile and shear strength of natural soil.

Main Raw Materials: Mostly polypropylene (PP) and polyester (PET), which are sun-resistant, acid-alkali resistant, and more durable than natural fibers (such as cotton and hemp).

Common Structures: There are two types—woven (high strength, low deformation) and non-woven (good puncture resistance, high friction). For complex projects, a composite type (combining the two) is used.

II. Core Functions

Soil Strengthening: Embedded in soil like "reinforcing bars" to make the soil firmer, preventing cracking and sliding (e.g., laying it on soft soil foundations for highway construction can improve the bearing capacity of roadbeds).

Load Dispersion: Spreads the pressure from vehicles or buildings over a larger area of soil, avoiding local soil damage due to overloading (e.g., laying it under railway tracks reduces track settlement).

Preventing Uneven Settlement: Slows down the compression rate of soft soil, narrows the settlement difference between different areas, and prevents cracks in pavements or embankments.

Auxiliary Filtration & Drainage: Prevents soil particles from being washed away by water, while allowing accumulated water to drain—maintaining soil strength.

III. Key Features

High Strength & Light Weight: Its strength is comparable to low-strength steel, but it is much lighter. No heavy equipment is needed for transportation and laying, reducing construction difficulty.

Good Environmental Adaptability: Usable in saline-alkali lands or under direct sunlight, with an outdoor service life usually exceeding 50 years.

High Cost-Effectiveness: Cheaper than traditional reinforcement methods (such as replacing soil with gravel or pouring concrete), and can shorten the construction period.

Simple Construction: No complex processes required; it can be quickly laid by manual work with small machinery.

Product Parameters

project | metric | ||||||||||

Nominal strength/(kN/m) | |||||||||||

6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |||

1 | Longitudinal and transverse tensile strength / (kN/m) ≥ | 6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |

2 | Maximum elongation at maximum load in longitudinal and transverse directions/% | 30~80 | |||||||||

3 | CBR top penetration strength /kN ≥ | 0.9 | 1.6 | 1.9 | 2.9 | 3.9 | 5.3 | 6.4 | 7.9 | 8.5 | |

4 | Longitudinal and transverse tearing strength /kN | 0.15 | 0.22 | 0.29 | 0.43 | 0.57 | 0.71 | 0.83 | 1.1 | 1.25 | |

5 | Equivalent aperture O.90(O95)/mm | 0.05~0.30 | |||||||||

6 | Vertical permeability coefficient/(cm/s) | K× (10-¹~10-), where K=1.0~9.9 | |||||||||

7 | Width deviation rate /% ≥ | -0.5 | |||||||||

8 | Unit area mass deviation rate /% ≥ | -5 | |||||||||

9 | Thickness deviation rate /% ≥ | -10 | |||||||||

10 | Thickness coefficient of variation (CV)/% ≤ | 10 | |||||||||

11 | Dynamic perforation | Puncture hole diameter/mm ≤ | 37 | 33 | 27 | 20 | 17 | 14 | 11 | 9 | 7 |

12 | Longitudinal and transverse fracture strength (grab method)/kN ≥ | 0.3 | 0.5 | 0.7 | 1.1 | 1.4 | 1.9 | 2.4 | 3 | 3.5 | |

13 | Ultraviolet resistance (Xenon arc lamp method) | Longitudinal and transverse strength retention rate% ≥ | 70 | ||||||||

14 | Ultraviolet resistance (fluorescence UV lamp method) | Longitudinal and transverse strength retention rate% ≥ | 80 | ||||||||

Product Application

1. Highway and Railway Engineering (One of the Core Scenarios)

Soft Foundation Treatment: Laid under roadbeds (especially in areas with soft soil or muck), they act like "soil reinforcing bars" to improve the bearing capacity of the foundation, preventing roadbed collapse and pavement cracking caused by long-term rolling of vehicles/trains.

Pavement Reinforcement: Placed between the base course of asphalt or cement pavements and the roadbed, they reduce cracks in the pavement caused by temperature changes (thermal expansion and contraction) or uneven loads, extending the service life of the pavement.

Railway Track Cushion: Placed between the railway ballast layer and the foundation, they disperse the heavy pressure of trains, reduce track settlement, and keep the track more level.

2. Water Conservancy and Water Transportation Engineering

Embankment/River Dyke Reinforcement: Laid on the inner side or in the middle of embankments, they enhance the embankment’s erosion resistance and sliding resistance (e.g., preventing soil on the embankment from being washed away during flood scouring) while assisting in drainage to avoid softening of the embankment due to water accumulation.

River Channel/Canal Slope Protection: Laid closely against the slopes of river channels, they are used in conjunction with stones or vegetation to prevent slope collapse caused by water scouring and protect the shape of the river channel.

Auxiliary Anti-Seepage for Reservoirs/Water Storage Tanks: Used together with anti-seepage membranes, they not only reinforce the soil under the membrane but also prevent soil particles from piercing the anti-seepage membrane, improving the anti-seepage effect.

3. Construction and Municipal Engineering

Filled Foundation Reinforcement: Laid in filled areas (e.g., foundations backfilled with gravel or miscellaneous soil) for factories, parking lots, and squares, they compact loose filled soil, reduce subsequent foundation settlement, and prevent building cracking.

Auxiliary for Underground Projects: For example, on the side walls or bottom of subway foundation pits and underground utility corridors, they are laid between the soil and support structures to disperse soil pressure and prevent deformation of the support structures.

Waste Landfills: Laid at the bottom and slopes of landfills; on one hand, they reinforce the soil to prevent landslides, and on the other hand, they work with anti-seepage layers to prevent landfill leachate from polluting the underground soil.

4. Slope and Mountain Protection

Embankment/Cut Slopes: For slopes along highways and railways (especially steep slopes), they fix the surface soil after being laid. When used with grass seeding or turf laying, they prevent slope collapse caused by rainwater scouring.

Mine Reclamation/Mountain Restoration: For bare slopes left after mining, they are laid on the soil surface to reinforce loose rock formations, provide a stable foundation for vegetation planting, and facilitate ecological restoration.

In summary, reinforced geotextiles have broad and indispensable applications across key engineering fields—spanning transportation (highways, railways), water conservancy, municipal construction, and ecological protection (slope and mine restoration). Their ability to target core soil challenges (instability, settlement, erosion) not only solves practical construction pain points but also delivers multi-faceted value: compared to traditional reinforcement methods (e.g., gravel replacement, concrete pouring), they cut costs and shorten construction periods; they extend the service life of infrastructure like roads and embankments; and they even support ecological recovery (such as mine reclamation). As a versatile, cost-effective geosynthetic material, reinforced geotextiles will remain a key solution for meeting stability and durability demands in various complex engineering projects.