Geomembrane Waterproofing

1. Excellent anti-seepage: Made of polymer with a tight molecular structure, the permeability coefficient is as low as 10 ⁻¹⁰ -10 ⁻¹² cm/s, which can effectively block water and liquid leakage.

2. Super durable: excellent weather resistance, resistance to ultraviolet radiation, oxidation, and temperature changes.

3. Convenient construction: The material is lightweight, easy to handle and lay, and can be cut according to project requirements. Hot melt welding and other connection methods can quickly form a seamless anti-seepage whole, greatly improving construction efficiency and shortening the construction period.

4. Widely applicable: Suitable for various fields such as water conservancy (reservoir and dam anti-seepage), agriculture (irrigation channel lining), environmental protection (wastewater treatment plants, sludge composting sites), and construction (basement and roof waterproofing), meeting the anti-seepage and waterproofing needs of different scenarios.

Products Introduction:

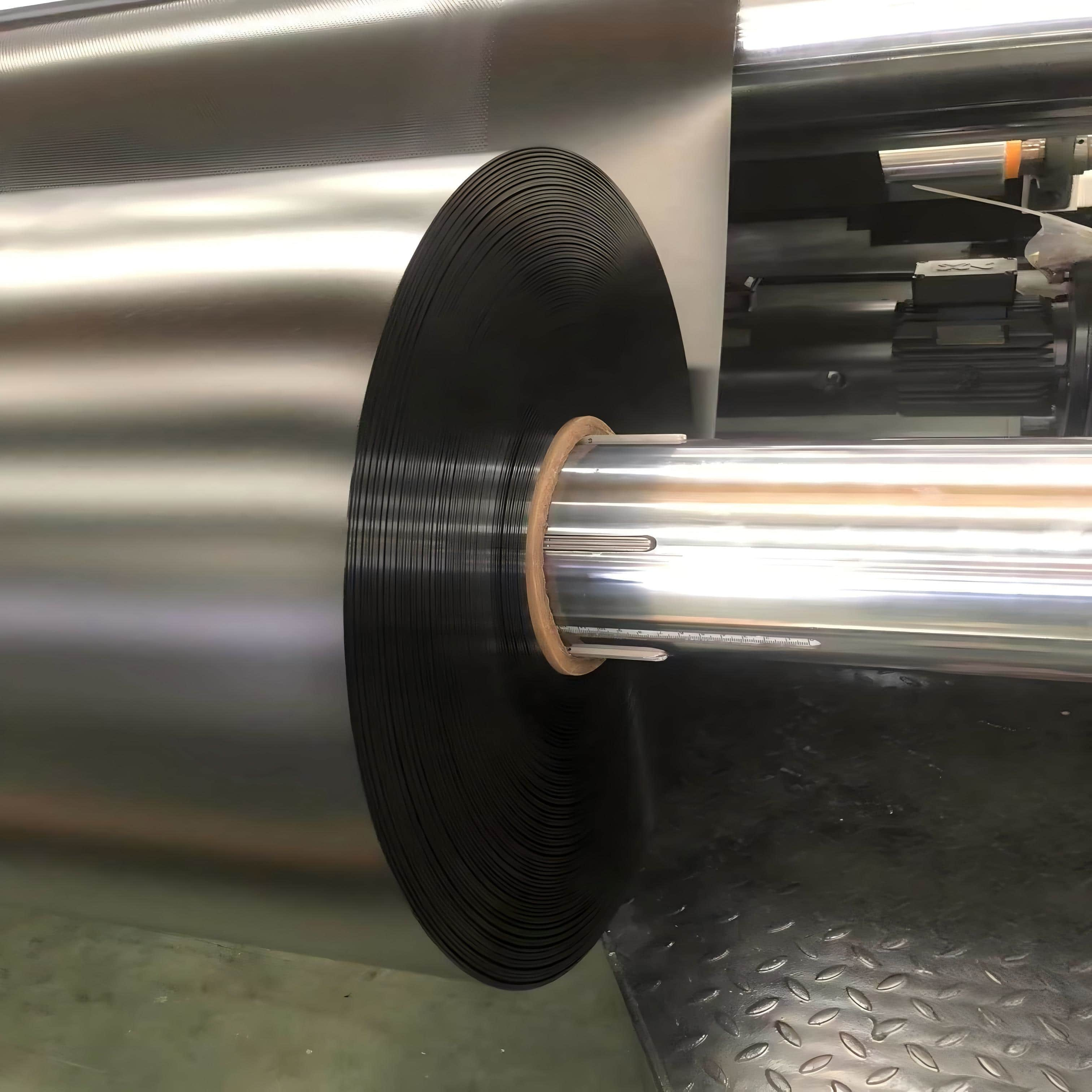

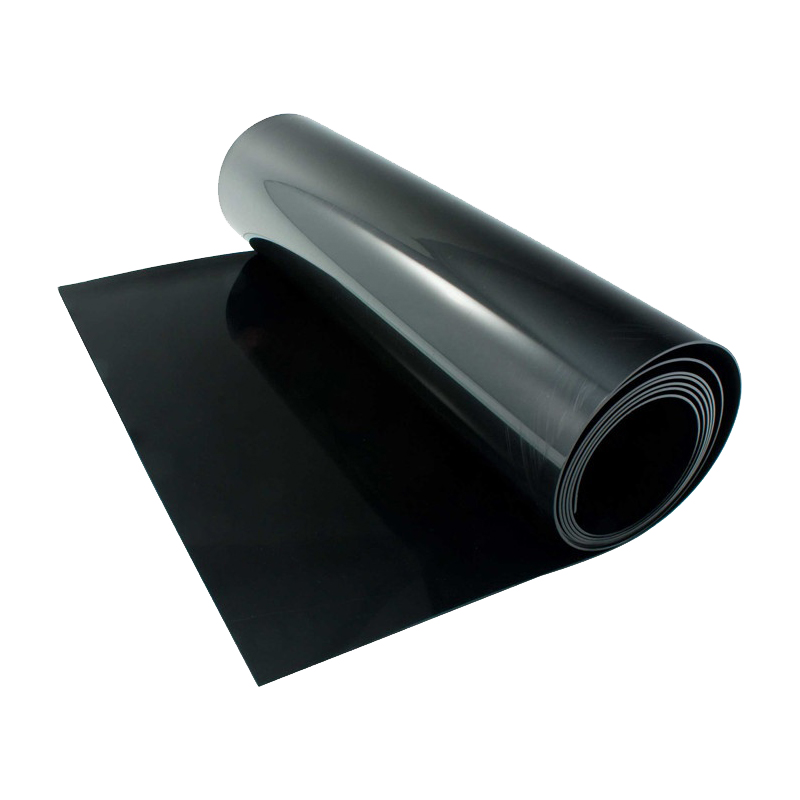

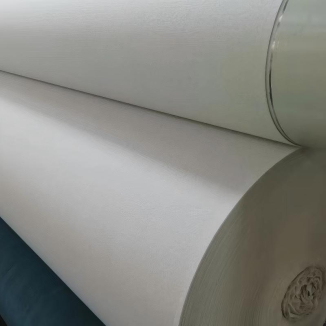

Geomembrane Waterproofing is a flexible waterproof material mainly made of high molecular weight polymers. Common raw materials include polyethylene (PE), polypropylene (PP), polyvinyl chloride (PVC), etc. It is processed through processes such as blow molding and rolling, and has a continuous and complete film structure. Its core function is to use its excellent anti-seepage performance to block the penetration path of liquids, while also having certain isolation and reinforcement effects. It is an indispensable key material in modern civil engineering, environmental engineering and other fields.

Product Features:

1. Excellent anti-seepage performance: The molecular structure of geomembranes is compact, which can effectively prevent the infiltration of water, chemical liquids, etc. Its permeability coefficient is usually as low as 10 ⁻¹⁰ -10 ⁻¹ cm/s, far superior to traditional anti-seepage materials, ensuring efficient anti-seepage effect in long-term use.

2. Excellent physical properties: It has high tensile strength and tear strength, can withstand external forces such as tension and compression during construction, and has good flexibility to adapt to the undulating changes of different terrains, ensuring that it does not break under complex working conditions.

3. Strong chemical stability: It has good corrosion resistance to chemicals such as acids, bases, and salts, and is stable in the pH range of 2-12. It can work reliably in environments with corrosive media such as chemical and environmental protection for a long time.

4. Outstanding weather resistance: It has excellent resistance to UV aging and high and low temperature performance, and can be used normally in the temperature range of -40 ℃ to 60 ℃. Its service life can reach decades in outdoor exposure environments, and it can resist long-term erosion from natural environments.

5. Convenient and efficient construction: The material is lightweight, much lighter than traditional waterproof materials, and the transportation and laying process is simple and labor-saving. By using hot melt welding, adhesive and other connection methods, a seamless anti-seepage layer can be quickly formed, greatly shortening the construction period and reducing construction costs.

Product Parameters:

| Metric | ASTM | unit | Test value | Minimum test frequency | ||||||

| test method | 0.75 mm | 1.00 mm | 1.25 mm | 1.50 mm | 2.00 mm | 2.50mm | 3.00 mm | |||

| Minimum average thickness | D5199 | mm | 0.75 | 1 | 1.25 | 1.5 | 2 | 2.5 | 3 | Per volume |

| Minimum value (any one of 10) | -10% | -10% | -10% | -10% | -10% | -10% | -10% | |||

| minimum density | D 1505/D 792 | g/cm3 | 0.94 | 0.94 | 0.94 | 0.94 | 0.94 | 0.94 | 0.94 | 90,000 kg |

| Minimum average tensile performance (1) | D638 Type IV | |||||||||

| Breakage strength, | N/mm | 20 | 27 | 33 | 40 | 53 | 67 | 80 | 9,000 kg | |

| yield strength | N/mm | 11 | 15 | 18 | 22 | 29 | 37 | 44 | ||

| Strain extension, | % | 700 | 700 | 700 | 700 | 700 | 700 | 700 | ||

| yield extension | % | 12 | 12 | 12 | 12 | 12 | 12 | 12 | ||

| Minimum strength of right-angle tear | D 1004 | N | 93 | 125 | 156 | 187 | 249 | 311 | 374 | 20,000 kg |

| Minimum puncture strength | D4833 | N | 240 | 320 | 400 | 480 | 640 | 800 | 960 | 20,000 kg |

| Constant tensile load stress cracking (2) | D5397 | hour | 300 | 300 | 300 | 300 | 300 | 300 | 300 | Based on GRI GM-10 |

| Carbon black content | D 1603(3) | % | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 9,000 kg |

| Carbon black dispersion | D5596 | Note (4) | Note (4) | Note (4) | Note (4) | Note (4) | Note (4) | Note (4) | 20,000 kg | |

| Oxygen induction time (OIT) (5) | 90,000 kg | |||||||||

| (a) Standard OIT | D3895 | minute | 100 | 100 | 100 | 100 | 100 | 100 | 100 | |

| (b) high-handed OIT | D5885 | minute | 400 | 400 | 400 | 400 | 400 | 400 | 400 | |

| 85℃ Oven aging (minimum average) (5)(6) | Per formula | |||||||||

| (A) Standard OIT is retained after 90 days | D 5721 | % | 55 | 55 | 55 | 55 | 55 | 55 | 55 | |

| (B) High voltage OIT is retained for 90 days | D 3895 D5885 | % | 80 | 80 | 80 | 80 | 80 | 80 | 80 | |

| Ultraviolet resistance (7) | Per formula | |||||||||

| (a) standard OIT | D3895 | Note (8) 50 | ||||||||

| (b) Retention of high pressure OIT after 1600 hours (9) | D5885 | % | ||||||||

Product Applications:

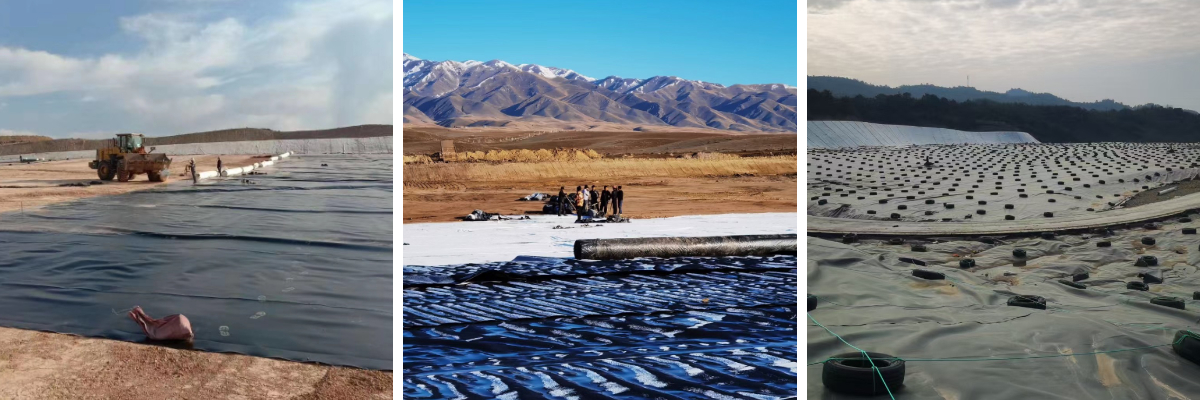

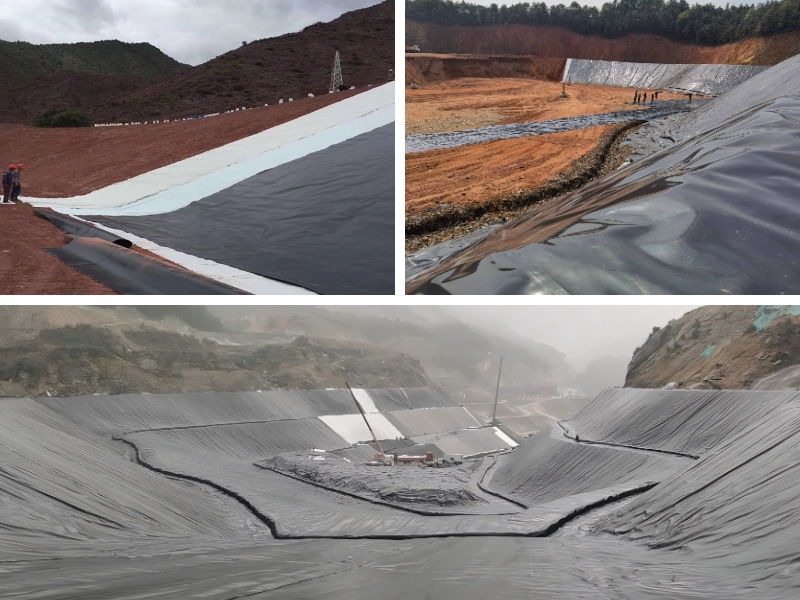

1. Water conservancy engineering: In projects such as reservoirs, dams, and channels, it is used for dam seepage prevention and channel lining to prevent water resource leakage, improve the water storage capacity and operational safety of water conservancy engineering. For example, after using geotextile lining for irrigation channels in farmland, the water utilization coefficient can be increased by more than 30%.

2. Environmental protection engineering: widely used in landfills, sewage treatment plants, sludge disposal sites, etc., it can effectively block the contact between leachate, sewage and soil, groundwater, prevent environmental pollution, and is an important anti-seepage barrier in environmental protection engineering.

3. Transportation engineering: plays a role in the reinforcement and anti-seepage of roadbeds in highways and railways, which can prevent settlement, deformation and other problems caused by water accumulation in roadbeds, and improve the stability and service life of roads; In tunnel engineering, it is used for waterproof lining to ensure the safety of tunnel structures.

4. Agricultural engineering: used for anti-seepage treatment of reservoirs, irrigation channels, fish ponds, etc., reducing water resource waste, improving irrigation efficiency and aquaculture benefits. For example, after laying geomembranes in fish ponds, water leakage can be reduced, water replacement frequency can be lowered, and costs can be saved.

5. Construction engineering: Applied in waterproofing projects such as basements, roofs, and bathrooms, as well as in water feature projects such as artificial lakes and landscape pools to achieve waterproofing and meet the waterproofing needs of buildings and landscapes.

As a high-performance anti-seepage material, geomembrane plays a crucial role in various engineering constructions due to its excellent anti-seepage performance, outstanding physical and chemical properties, wide application fields, and convenient construction methods. It can not only effectively protect water resources, prevent environmental pollution, improve engineering quality and safety, but also save resources, reduce costs, and extend the service life of engineering. With the continuous development of the engineering construction field and the increasing demand for environmental protection and water conservation, the application prospects of geomembranes will be even broader, providing strong support for promoting the green and efficient construction of engineering projects. They are an indispensable ideal material in modern engineering construction.