Geotextile Drainage Mat

1.Efficient Drainage: The three-dimensional structure quickly drains accumulated water, preventing structural damage caused by soil softening.

2.Strong Stability: The composite structure prevents clogging, enhances soil strength, and reduces engineering risks.

3.Convenient Construction & Cost Savings: Lightweight and easy to transport, it enables simple construction and reduces excavation work and costs.

4.Weather & Corrosion Resistance: High-performance materials adapt to harsh environments, ensuring a long service life and minimal maintenance.

Product Introduction

I. Basic Properties

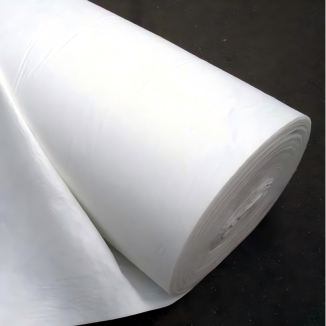

Material Composition: Geotextile Drainage Mat are typically made of a core polymer material, such as high-density polyethylene (HDPE) or polypropylene (PP), combined with a geotextile filter layer to form a composite structure that combines durability with excellent filtration performance.

Structural Form: They utilize a three-dimensional design with porous channels (similar to the pores of a polymer core) and a geotextile outer layer. The entire structure can be manufactured and shipped in rolls, typically with a thickness of 5-20mm and a weight of only 2-5kg per square meter.

II. Core Functions

Efficient Drainage: Three-dimensional porous channels create a continuous drainage path, rapidly collecting and draining excess water from the soil. The drainage rate is 3-5 times faster than traditional gravel drainage layers, effectively reducing soil pore water pressure.

Structural Reinforcement: The geotextile in the composite structure blocks soil particles from entering the drainage channel, preventing blockage. The core material provides stable support, enhancing the soil's overall shear strength, reducing risks such as subgrade settlement and slope landslides, and improving the bearing stability of the project.

Environmental Adaptability: Thanks to its ageing and chemical-resistant properties, it maintains stable performance in extreme temperatures of -30°C to 80°C, as well as in harsh environments such as acidic and alkaline soils and saline-alkali land, avoiding the rust and compaction problems often encountered with traditional systems.

III. Key Features

Easy Construction: No complex grading or mixing is required; on-site construction requires only laying and splicing. Compared to traditional gravel drainage systems, construction efficiency is increased by over 50%. Furthermore, it is lightweight and easy to transport, reducing on-site work complexity.

Cost Control: Its thin design reduces excavation depth, saving earthwork and transportation costs. The overall construction cost is 20%-30% lower than traditional systems, and its service life can reach over 50 years, reducing the frequency and cost of ongoing maintenance.

Wide Application: It can be used in a variety of construction scenarios, including roadbeds, basements, slopes, roads, and airport runways. It is particularly well-suited for projects in areas with high rainfall or high moisture content, as well as those under heavy loads and harsh environments.

Product Parameters

project | metric | ||||||||||

Nominal strength/(kN/m) | |||||||||||

6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |||

1 | Longitudinal and transverse tensile strength / (kN/m) ≥ | 6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |

2 | Maximum elongation at maximum load in longitudinal and transverse directions/% | 30~80 | |||||||||

3 | CBR top penetration strength /kN ≥ | 0.9 | 1.6 | 1.9 | 2.9 | 3.9 | 5.3 | 6.4 | 7.9 | 8.5 | |

4 | Longitudinal and transverse tearing strength /kN | 0.15 | 0.22 | 0.29 | 0.43 | 0.57 | 0.71 | 0.83 | 1.1 | 1.25 | |

5 | Equivalent aperture O.90(O95)/mm | 0.05~0.30 | |||||||||

6 | Vertical permeability coefficient/(cm/s) | K× (10-¹~10-), where K=1.0~9.9 | |||||||||

7 | Width deviation rate /% ≥ | -0.5 | |||||||||

8 | Unit area mass deviation rate /% ≥ | -5 | |||||||||

9 | Thickness deviation rate /% ≥ | -10 | |||||||||

10 | Thickness coefficient of variation (CV)/% ≤ | 10 | |||||||||

11 | Dynamic perforation | Puncture hole diameter/mm ≤ | 37 | 33 | 27 | 20 | 17 | 14 | 11 | 9 | 7 |

12 | Longitudinal and transverse fracture strength (grab method)/kN ≥ | 0.3 | 0.5 | 0.7 | 1.1 | 1.4 | 1.9 | 2.4 | 3 | 3.5 | |

13 | Ultraviolet resistance (Xenon arc lamp method) | Longitudinal and transverse strength retention rate% ≥ | 70 | ||||||||

14 | Ultraviolet resistance (fluorescence UV lamp method) | Longitudinal and transverse strength retention rate% ≥ | 80 | ||||||||

Product Application

1. Civil Engineering

Roadbed Engineering: During highway and railway roadbed construction, geotextile drainage mats are laid between the subgrade and the soil to quickly drain water from the subgrade, preventing subgrade settlement and cracking caused by soil softening. They are particularly suitable for rainy areas or sections with high groundwater levels, ensuring long-term roadbed stability and extending the service life of the road.

Slope Protection: Whether it's a road slope, river slope, or mine reclamation slope, geotextile drainage mats can quickly drain excess moisture from the soil, reducing pore water pressure and minimizing the risk of landslides and collapses. Furthermore, their composite structure prevents soil particle loss and, when combined with vegetation protection, further enhances slope protection.

2. Construction Engineering

Basements and Underground Garages: Geotextile drainage mats are laid on the exterior walls and floor slabs of basements to create drainage channels, quickly directing water seepage from the soil, preventing leakage, dampness, and mold on the walls, ensuring dry underground spaces and reducing future waterproofing and maintenance costs.

Green Roof Projects: Drainage layers used in green roofs drain excess rainwater from the soil, preventing waterlogging and root rot. They also reduce excessive roof loads, protect the roof's waterproofing layer, and extend the lifespan of the green roof system.

3. Transportation and Municipal Engineering

Airport Runway Projects: Airport runways require extremely high foundation stability. Geotextile drainage mats, laid beneath the runway subgrade, effectively drain rainwater and groundwater, preventing the runway subgrade from softening due to accumulated water, cracking, and subsidence, ensuring safe aircraft takeoff and landing.

Municipal Pipeline Network Projects: During the installation of municipal stormwater and sewage pipelines, geotextile drainage mats are laid around the perimeter of the pipelines to quickly drain accumulated water, prevent soil collapse that could cause deformation and rupture of the pipelines, reduce maintenance requirements, and ensure the normal operation of the municipal drainage system.

4.Special Environmental Engineering Fields

Saline-alkali land improvement projects: In saline-alkali land management, geotextile drainage mats can accelerate the drainage of saline-alkali water from the soil. Combined with salt leaching, they can reduce soil salinity, create suitable conditions for vegetation cultivation, and contribute to the ecological restoration and agricultural utilization of saline-alkali land.

Landfill projects: Installed above the landfill's impermeable layer, they can drain leachate, preventing its accumulation and damage from excessive pressure. They also reduce leachate contamination of surrounding soil and groundwater, improving the landfill's environmental friendliness and safety.

In summary, geotextile drainage mats, with their core advantages of efficient drainage, structural stability, and weather and corrosion resistance, have become widely applicable in a wide range of fields, including civil engineering, construction, transportation, municipal engineering, and special environmental engineering. Their application not only effectively addresses water accumulation hazards, structural stability, and environmental safety issues in various projects, but also provides key support for high-quality construction and long-term operation and maintenance of various projects by simplifying construction, reducing costs, and extending project life. They have become an indispensable functional material in modern engineering construction.