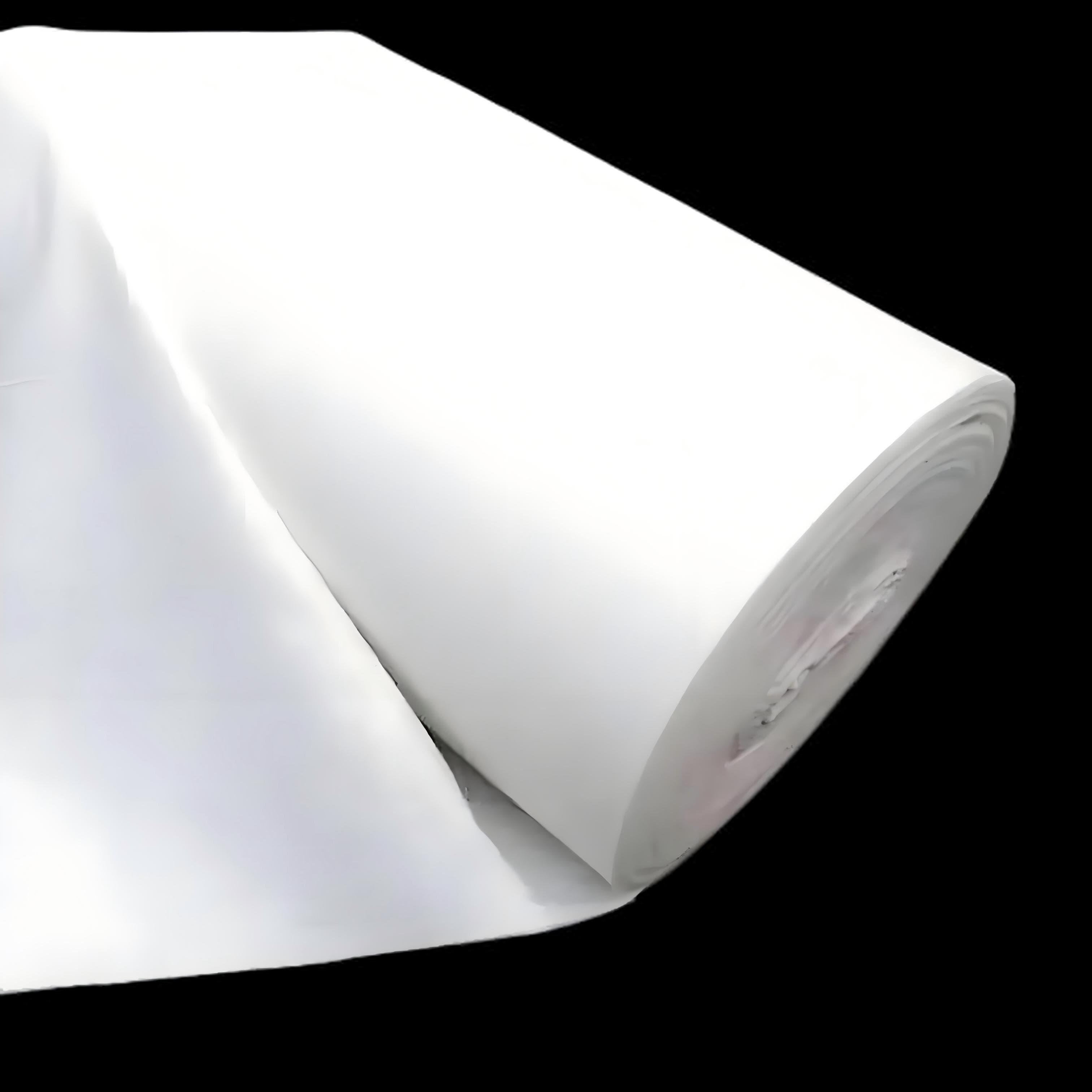

Heavy Duty Geotextile

1.High-Strength and Tensile Resistance: Made of high-strength fiber, it withstands rolling loads and resists soil deformation to protect the structure.

2.Strong Protection and Isolation: It prevents material contamination, cushions impacts and resists erosion, ensuring project stability.

3.Weather-Resistant and Durable: Specially treated to withstand extreme environments, it offers a long lifespan and reduces maintenance costs.

4.Suitable for Heavy-Duty Projects: High performance suitable for demanding projects, replacing traditional materials for improved quality and simplified construction.

Product Introduction

I. Basic Properties

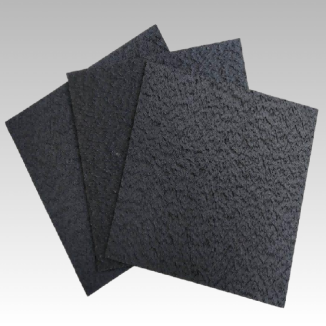

Material Composition: Heavy Duty Geotextile are made from high-tenacity fibers, commonly polyester and polypropylene filaments, through weaving and needle-punching processes. Some products receive additional treatments for anti-aging and chemical corrosion resistance to enhance durability.

Structure and Performance: The fabric boasts a dense structure and high fiber strength, with longitudinal and transverse tensile strength generally exceeding 200 kN/m. Thickness and weight are greater than those of ordinary geotextiles, providing the physical foundation to withstand heavy loads. It can be produced and transported in rolls, making it easy to lay on-site.

II. Core Functions

Load-bearing and Deformation Resistance: With its high strength, it can withstand heavy machinery, soil weight, and external engineering loads, effectively resisting soil tensile deformation, preventing damage to roadbeds, embankments, and other engineering structures due to material fracture, thereby ensuring structural stability.

Isolation and Protection: It precisely separates soil, sand, gravel, or filler particles of varying particle sizes, preventing material mixing that could affect engineering performance. It also cushions external impacts, blocks penetration from sharp objects, and resists water erosion, reducing wear and erosion on engineering structures.

Environmental Adaptability: After special treatment, it maintains stable performance in complex environments such as -40°C to 80°C, acidic and alkaline soils, saline-alkali land, and sewage, resisting degradation, rusting, or embrittlement, ensuring continued engineering performance under harsh conditions.

III. Key Features

Application Focused on Heavy-Duty Engineering: Its robust performance makes it ideal for heavy-duty or high-specification projects requiring extreme strength and durability, such as highway and railway roadbed reinforcement, large-scale dam construction, landfill anti-seepage layer protection, and mine reclamation.

Significant Cost-Effectiveness: It can replace traditional heavy protective materials (such as stone and metal mesh), improving project quality while reducing material transportation and construction difficulties and streamlining the construction process. Its service life can reach over 30 years, significantly reducing maintenance frequency and costs.

Strong Functionality: It integrates multiple functions, including high-strength load-bearing, isolation, protection, and weather and corrosion resistance, eliminating the need for multiple single-function materials. This single-stop solution solves multiple engineering challenges, improving construction efficiency and overall project reliability.

Product Parameters

project | metric | ||||||||||

Nominal strength/(kN/m) | |||||||||||

6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |||

1 | Longitudinal and transverse tensile strength / (kN/m) ≥ | 6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |

2 | Maximum elongation at maximum load in longitudinal and transverse directions/% | 30~80 | |||||||||

3 | CBR top penetration strength /kN ≥ | 0.9 | 1.6 | 1.9 | 2.9 | 3.9 | 5.3 | 6.4 | 7.9 | 8.5 | |

4 | Longitudinal and transverse tearing strength /kN | 0.15 | 0.22 | 0.29 | 0.43 | 0.57 | 0.71 | 0.83 | 1.1 | 1.25 | |

5 | Equivalent aperture O.90(O95)/mm | 0.05~0.30 | |||||||||

6 | Vertical permeability coefficient/(cm/s) | K× (10-¹~10-), where K=1.0~9.9 | |||||||||

7 | Width deviation rate /% ≥ | -0.5 | |||||||||

8 | Unit area mass deviation rate /% ≥ | -5 | |||||||||

9 | Thickness deviation rate /% ≥ | -10 | |||||||||

10 | Thickness coefficient of variation (CV)/% ≤ | 10 | |||||||||

11 | Dynamic perforation | Puncture hole diameter/mm ≤ | 37 | 33 | 27 | 20 | 17 | 14 | 11 | 9 | 7 |

12 | Longitudinal and transverse fracture strength (grab method)/kN ≥ | 0.3 | 0.5 | 0.7 | 1.1 | 1.4 | 1.9 | 2.4 | 3 | 3.5 | |

13 | Ultraviolet resistance (Xenon arc lamp method) | Longitudinal and transverse strength retention rate% ≥ | 70 | ||||||||

14 | Ultraviolet resistance (fluorescence UV lamp method) | Longitudinal and transverse strength retention rate% ≥ | 80 | ||||||||

Product Application

1. Transportation Infrastructure Engineering

Highway and Railway Roadbed: Laid between the roadbed base and filler, its high-strength and tensile strength allows it to withstand heavy rollers and long-term train loads, preventing subsidence and cracking due to uneven loads. It also separates fillers of different particle sizes, preventing material mixing that affects roadbed compaction, and ensuring structural stability after the roads and railways open to traffic.

Airport Runway Construction: Laid beneath and around the runway base, it resists the massive impact of aircraft takeoff and landing, cushions the penetration of sharp objects into the base, and separates gravel from soil, preventing damage to the runway due to material mixing or external forces, ensuring the long-term safe operation of the airport runway.

2. Water Conservancy and Dam Engineering

Large Dams and Flood Control Levees: Covering the water-facing slope or the interior of the levee, it effectively protects against water erosion and reduces soil erosion. It also separates different fillers within the levee, preventing soil loss and leakage. It also withstands flood shock loads, enhancing the levee's flood resistance and service life.

River and Reservoir Management: Used in river bank reinforcement and reservoir slope protection, it buffers water erosion and prevents soil particle loss. Combined with ecological vegetation planting, it provides a dual "protection + ecology" approach, preventing river and reservoir slope collapse and maintaining the ecological and structural safety of water conservancy facilities.

3. Environmental Protection and Special Engineering

Landfills: Paved above the landfill's impermeable layer, it acts as a protective layer against heavy machinery and sharp debris punctures during the landfill process, protecting the impermeable layer from damage and preventing leachate from contaminating the soil and groundwater. It also isolates the waste from the impermeable layer, reducing the risk of corrosion.

Mine Reclamation: During mine reclamation, it is laid between the reclaimed soil and the underlying slag, isolating the slag from the planting soil and preventing harmful substances from seeping into the soil and affecting vegetation growth. Its high strength allows it to withstand the mechanical loads of the reclamation process, stabilize the site structure, and create conditions for vegetation restoration.

4. Municipal and Construction Engineering

Large Parking Lot and Plaza Foundations: Paved during the foundation preparation phase, this reinforces the foundation's bearing capacity, withstands the loads of long-term vehicle parking, and prevents ground settlement and cracking. It also isolates the foundation filler from the surface soil, preventing material mixing that affects foundation stability and extending the service life of parking lots and plazas.

Underground Pipeline Corridor Construction: Paved around the perimeter of the pipeline corridor, it cushions external impacts during construction and operation, preventing excessive soil pressure or damage to the corridor structure from sharp objects. It also isolates the soil surrounding the corridor from the backfill material, reducing compression on the corridor from soil settlement and ensuring safe operation.

In summary, heavy-duty geotextiles, with their core advantages of high tensile strength, strong protection and isolation, and weather and corrosion resistance, are highly suitable for heavy-duty or high-demand projects in a variety of fields, including transportation infrastructure, water conservancy dams, environmental protection, and municipal construction. Their application not only addresses key issues such as load tolerance, structural protection, and material isolation in different scenarios, but also provides reliable support for high-quality construction and long-term operation and maintenance of various projects by improving project stability, extending service life, and simplifying construction processes. This makes them an indispensable functional material in modern heavy-duty engineering.