Geo Synthetic Tubes

Strong Soil and Water Conservation: High permeability allows for the proper drainage of water while firmly locking in soil particles, effectively preventing soil erosion. Suitable for applications such as slope protection and river management.

Environmentally Friendly: Made from polymer materials, it reduces engineering pollution and meets ecological engineering requirements.

Aging and Abrasion Resistance: The fabric is treated with UV and corrosion resistance to withstand harsh weather and mechanical friction, extending the lifespan of the project.

Easy and Low-Cost Construction: Lightweight, efficient transportation and installation. No complex equipment is required, significantly shortening construction schedules and reducing labor and time costs.

Product Introduction:

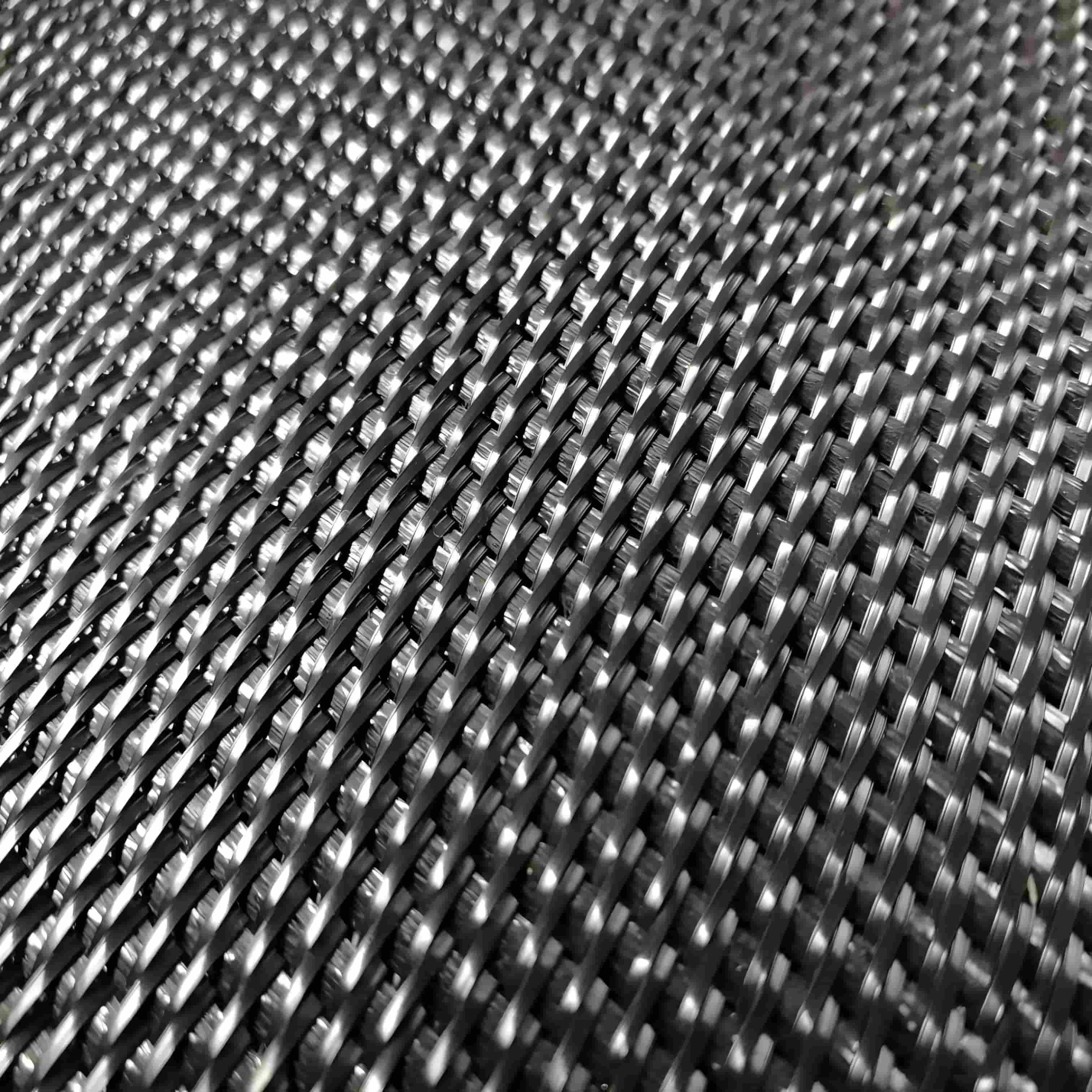

Geo Synthetic Tubes also highlight their design details and sustainable value. In terms of structural design, some high-end styles utilize a double-layer composite fabric. The inner layer retains basic filtration and load-bearing functions, while the outer layer features an additional puncture-resistant coating to protect the bag from damage by sharp rocks and roots, making it particularly suitable for construction sites in complex terrains such as mines and mountainous terrain. High-strength sewn drawstrings and buckles at the bag opening allow for quick tightening after filling, eliminating leaks associated with traditional tying methods and further enhancing ease of installation.

In terms of sustainability, geotextile bags are made from recycled polymer fibers, transforming industrial waste plastics and discarded fishing nets into high-performance raw materials. This reduces solid waste pollution and lowers reliance on virgin resources, aligning with the global trend toward a "circular economy." In addition, the product can also provide support for ecological restoration during use. In river bank protection or mine greening projects, geotextile bags filled with soil can form a stable microenvironment, providing a growth carrier for herbaceous plants and aquatic organisms. After the vegetation takes root, the bag gradually merges with the natural environment, realizing the transition from "engineering protection" to "ecological self-sustaining", truly achieving a balance between short-term engineering benefits and long-term ecological value.

Product Parameters:

project | unit | CWGD50S | CWGD90/120 | CWGD90S | CWGD100S | CWGD120S-B | CWGD120S-C | CWGD130S | CWGD200S-C | |

Tensile strength-radial | kN/m | 55 | 90 | 90 | 100 | 130 | 130 | 130 | 220 | |

Tensile strength-Weft | 50 | 120 | 90 | 100 | 120 | 120 | 130 | 210 | ||

Strain elongation-radial | % | 16±1 | 12±1 | 9±1 | 10±1 | 10±1 | 10±1 | 10±1 | 12±1 | |

Extensional elongation-Weft | 10±1 | 8±1 | 8±1 | 8±1 | 8±1 | 8±1 | 8±1 | 8±1 | ||

Breakage strength at 2% elongation | warp direction | kN/m | 5/15 | 14/40 | 30/30 | 30/30 | 20/40 | 22/40 | 20/45 | 15 |

Breakage strength at 5% elongation | warp direction | kN/m | 14/33 | 38/90 | 75/75 | 75/75 | 80/100 | 84/40 | 80/110 | 90 |

mass area ratio | g/m² | 285 | 440 | 390 | 430 | 540 | 540 | 560 | 850 | |

Joint tensile strength | kN/m | 35 | 90 | 60 | 70 | 100 | 100 | 110 | 170 | |

Static Burst Strength (CBR) | KN | 5 | 10 | 10 | 13 | 15 | 15 | 16 | 22 | |

Dynamic perforation | mm | 10 | 8 | 12 | 12 | 10 | 10 | 11 | 8 | |

Equivalent aperture (0g0) | mm | 0.9 | 0.48 | 0.52 | 0.45 | 0.4 | 0.3 | 0.43 | 0.4 | |

Permeability (Q50) | L/m²/s | 200 | 40 | 20 | 15 | 12 | 6.5 | 15 | 15 | |

Ultraviolet resistance (500h strong storage rate ) | % | 90 | 90 | 85 | 85 | 85 | 85 | 85 | 85 | |

Product Applications:

Geotextile Fabric Bags, with their versatility and adaptability, demonstrate irreplaceable application value in a variety of engineering and ecological fields, including the following:

Water Conservancy Engineering

Geotextile bags are a core protective material for river management, embankment reinforcement, and reservoir slope protection. During construction, the bags are filled with local sand, gravel, or soil and stacked in layers. Their excellent permeability allows for rapid drainage of internal water accumulation caused by rainwater or river water infiltration, preventing slope landslides caused by water pressure. Furthermore, the tightly stacked bags resist erosion and prevent soil erosion along the riverbanks. For example, in urban black and odorous water treatment projects, geotextile bags are used to construct ecological revetments, which not only stabilize the shoreline but also provide root space for aquatic plants, aiding the recovery of aquatic ecosystems.

Transportation Infrastructure

In road and railway construction, geotextile bags can address the challenges of soft soil foundations. For soft soil areas with insufficient bearing capacity beneath the roadbed, geotextile bags filled with crushed stone are buried within the soft soil layer. The bags' high strength distributes the roadbed load, reducing settlement and deformation. Furthermore, their filtration properties prevent soft soil particles from migrating with water, preventing cavities in the roadbed. Furthermore, in highway slope greening projects, geotextile bags filled with planting soil can be laid directly on the slope to quickly form a greening base, preventing dust and soil erosion caused by exposed slopes, and balancing infrastructure strength with road aesthetics.

Ecological Restoration

Mine greening, landslide control, and wetland protection are important applications for geotextile bags. In abandoned mine pit restoration, geotextile bags filled with improved soil are laid along the pit slope. The bags stabilize the soil, providing a stable environment for planting trees and shrubs while preventing soil loss caused by rainwater erosion. In areas prone to landslides, stacked geotextile bags can form temporary anti-slip retaining walls, which, when combined with anchor bolts, can quickly curb landslide trends. In wetland restoration projects, biodegradable geobags can slowly blend into the environment, helping to stabilize the wetland's base soil without disrupting its ecological balance.

Municipal and Agricultural Sector

In municipal engineering, geobags can be used to reinforce the soil around urban drainage networks. During excavation and backfill, geobags are used to wrap the backfill soil to prevent soil subsidence and rupture of the network. Their permeability also aids drainage and reduces water pressure in the network. In agriculture, geobags can be used to construct terraces or reservoir embankments. Especially in hilly areas, soil-filled geobags can quickly create small terraces, prevent soil erosion caused by sloping land, and improve land utilization.

Geotextile Fabric Bags are geosynthetic products with water permeability, high strength and environmental adaptability. Their core advantage lies in their ability to achieve protection, reinforcement and ecological synergy by filling with materials such as sand, gravel and soil. They are widely used in four major fields: in water conservancy projects, they are used for river management, embankment reinforcement, and anti-scouring and anti-landslide; in transportation infrastructure, they solve soft soil foundation problems and help stabilize highway and railway roadbeds and green slopes; in ecological restoration, they participate in mine greening, landslide control and wetland protection, taking into account both stability and eco-friendliness; in the municipal and agricultural fields, they can reinforce the soil around drainage pipes and construct terraces, improving project safety and land utilization rate. They are engineering materials that are both functional and sustainable.