Geo Fabric Retaining Wall

1. Efficient filtration and permeability: Accurately intercepting particles, ensuring smooth drainage, balancing soil and water infiltration, and avoiding clogging.

2. Strong and tear resistant: High strength fiber interweaving, resistant to tensile wear, and adaptable to complex terrain stress.

3. Excellent weather resistance: resistant to ultraviolet rays, acid and alkali corrosion, long-lasting maintenance performance, and extended engineering life.

4. Convenient and economical construction: Lightweight and easy to cut and lay, saving labor and time, and reducing overall costs.

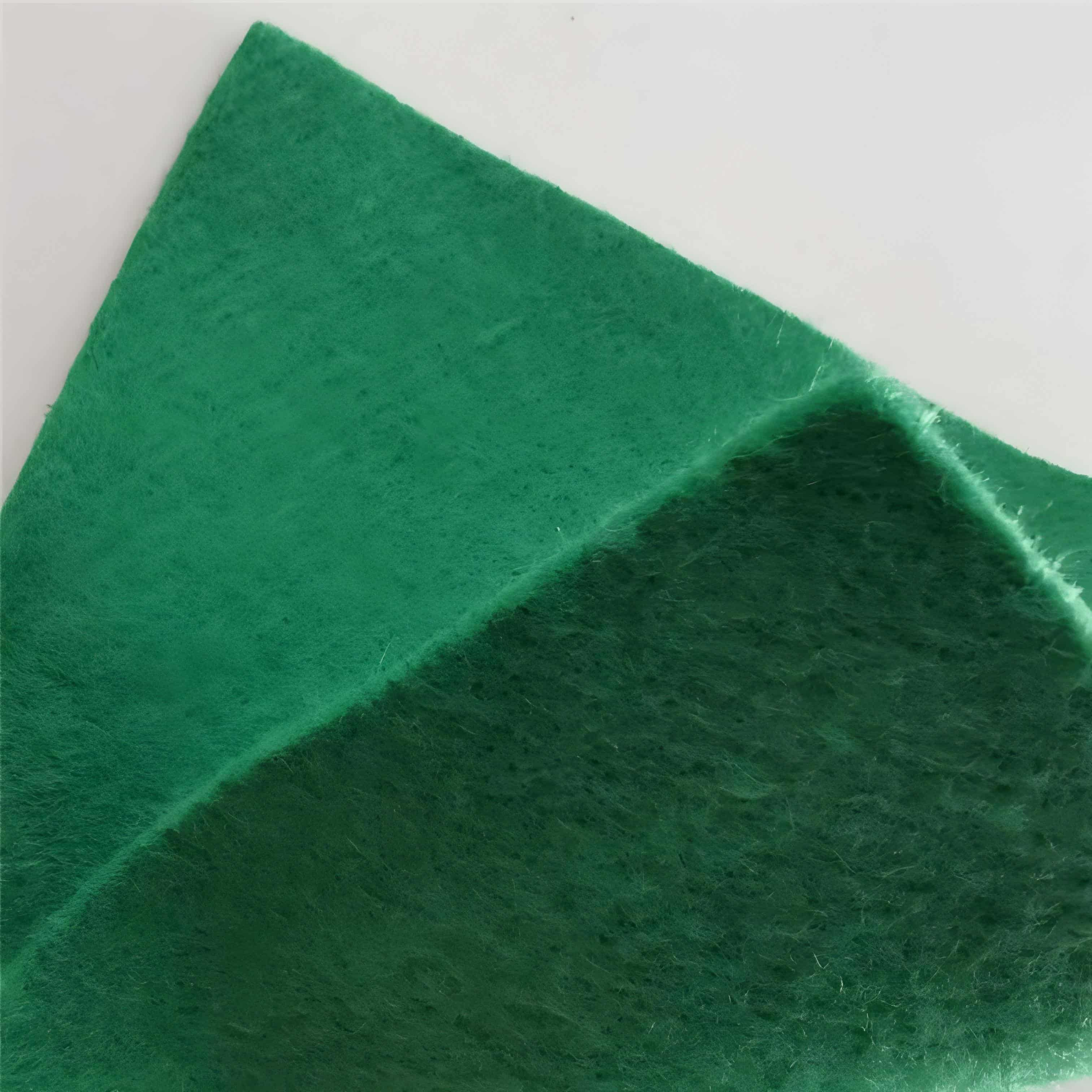

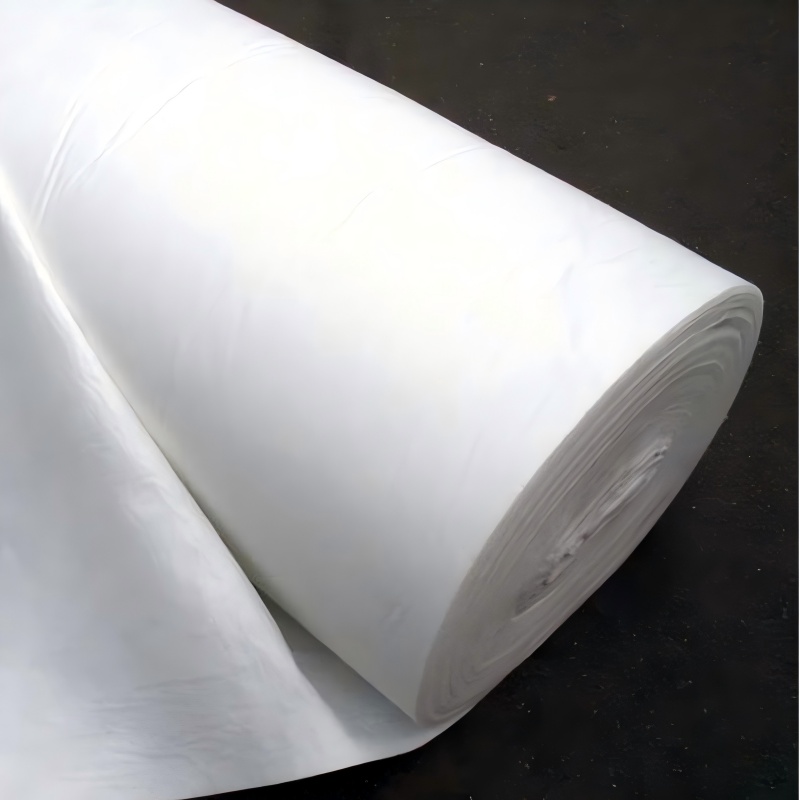

Products Introduction:

Geo Fabric Retaining Wall is a permeable geosynthetic material made from synthetic fibers such as polypropylene, polyester, etc., through processes such as needle punching, weaving, or hot rolling. It has high strength, flexibility, and corrosion resistance, and can play key roles in various geotechnical engineering such as filtration, drainage, isolation, and reinforcement. As a new type of engineering material, its structural design balances functionality and practicality, and can choose different specifications (such as thickness, unit area mass, aperture, etc.) according to different engineering needs, adapting to various construction scenarios.

Product Features:

1. Efficient filtration and permeability: With precise pore size design, it can effectively intercept soil particles, prevent soil erosion, and ensure smooth water infiltration, avoiding structural failure caused by blockage in engineering and balancing the infiltration relationship between water and soil.

2. Strong and tear resistant: Made of high-strength interwoven fibers, it has excellent tensile and wear resistance, can adapt to stress changes in complex terrain, is not easily damaged under soil settlement and external loads, and ensures the stability of engineering structures.

3. Excellent weather resistance: It has good UV resistance and can resist aging caused by long-term exposure to sunlight; Simultaneously resistant to acid and alkali, and resistant to chemical corrosion, it can maintain long-term performance in different soil environments (such as saline alkali land and polluted soil), significantly extending the service life of the project.

4. Convenient and economical construction: With a lightweight texture and much lower weight than traditional engineering materials, it is easy to cut, lay, and splice without the need for complex construction equipment and professional skills, which can significantly shorten the construction period, reduce labor and transportation costs, and improve the overall efficiency of the project.

5. Multi functional adaptation: In addition to the core filtering and reinforcement functions, it can also play an isolation role (separating soil, sand and gravel materials of different particle sizes), preventing the mixing of different media from affecting engineering performance, achieving "one material for multiple uses", and simplifying the construction process.

Product Parameters:

project | metric | ||||||||||

Nominal strength/(kN/m) | |||||||||||

6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |||

1 | Longitudinal and transverse tensile strength / (kN/m) ≥ | 6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |

2 | Maximum elongation at maximum load in longitudinal and transverse directions/% | 30~80 | |||||||||

3 | CBR top penetration strength /kN ≥ | 0.9 | 1.6 | 1.9 | 2.9 | 3.9 | 5.3 | 6.4 | 7.9 | 8.5 | |

4 | Longitudinal and transverse tearing strength /kN | 0.15 | 0.22 | 0.29 | 0.43 | 0.57 | 0.71 | 0.83 | 1.1 | 1.25 | |

5 | Equivalent aperture O.90(O95)/mm | 0.05~0.30 | |||||||||

6 | Vertical permeability coefficient/(cm/s) | K× (10-¹~10-), where K=1.0~9.9 | |||||||||

7 | Width deviation rate /% ≥ | -0.5 | |||||||||

8 | Unit area mass deviation rate /% ≥ | -5 | |||||||||

9 | Thickness deviation rate /% ≥ | -10 | |||||||||

10 | Thickness coefficient of variation (CV)/% ≤ | 10 | |||||||||

11 | Dynamic perforation | Puncture hole diameter/mm ≤ | 37 | 33 | 27 | 20 | 17 | 14 | 11 | 9 | 7 |

12 | Longitudinal and transverse fracture strength (grab method)/kN ≥ | 0.3 | 0.5 | 0.7 | 1.1 | 1.4 | 1.9 | 2.4 | 3 | 3.5 | |

13 | Ultraviolet resistance (Xenon arc lamp method) | Longitudinal and transverse strength retention rate% ≥ | 70 | ||||||||

14 | Ultraviolet resistance (fluorescence UV lamp method) | Longitudinal and transverse strength retention rate% ≥ | 80 | ||||||||

Product Applications:

1. Water conservancy engineering: used in river regulation, reservoir embankment, channel anti-seepage and other projects to filter sediment in water bodies and prevent deformation of embankments and channels due to blockage; At the same time, as an anti filter layer, it protects anti-seepage materials such as geomembranes and enhances the safety of water conservancy facilities.

2. Transportation engineering: In the roadbed treatment of highways and railways, the roadbed soil and sand and gravel cushion layer can be isolated to avoid mixing of different materials; By reinforcing the roadbed, the bearing capacity is enhanced, reducing road settlement and cracking, and improving the service life of the road.

3. Municipal engineering: laying underground pipelines (such as sewage pipes and rainwater pipes) around the city, which can filter impurities in groundwater and prevent soil erosion around the pipelines; In landfills, it serves as an isolation layer and filter layer to prevent the infiltration and diffusion of pollutants.

4. Construction engineering: In the treatment of building foundations and slope protection, the reinforcement and tear resistance properties are utilized to stabilize the slope soil and prevent landslides and collapses; In roof greening and underground garage roof drainage systems, play a role in drainage filtration to ensure the safety of building structures.

5. Agriculture and Ecological Engineering: Used for filtering and anti-seepage in agricultural irrigation channels to improve water resource utilization efficiency; In ecological restoration projects such as mine greening and wetland construction, auxiliary soil fixation and vegetation restoration are used to improve the ecological environment.

Geo Fabric Retaining Wall, as a high-performance geosynthetic material, has become an indispensable key material in modern geotechnical engineering due to its core advantages such as efficient filtration and permeability, toughness and tear resistance, excellent weather resistance, and convenient construction. Its multifunctionality makes it widely used in various fields such as water conservancy, transportation, municipal engineering, construction, ecology, etc. It can not only solve problems such as blockage, settlement, aging caused by insufficient material properties in traditional engineering, but also improve engineering efficiency by simplifying construction processes and reducing costs. In the current pursuit of engineering quality and environmental benefits, Geotech Cloth provides efficient and economical solutions for various projects with its reliable performance and wide applicability, promoting the development of engineering construction towards a greener and more stable direction, and has important practical value and market potential.