Sediment Filtration Bags

1. High cost-effectiveness: It saves a lot of transportation costs because the volume of solid that needs to be disposed of after on-site dehydration is greatly reduced.

2. Environmentally friendly: Almost no secondary pollution is generated, and the intercepted pollutants are safely enclosed in bags. Avoiding the risk of leakage of dredged materials during transportation.

3. Efficient and fast construction: The construction speed is fast, and continuous pumping and filling operations can be carried out.

4. Safety and stability: The formed consolidated structure is stable and can be used as part of a permanent structure.

Product Introduction:

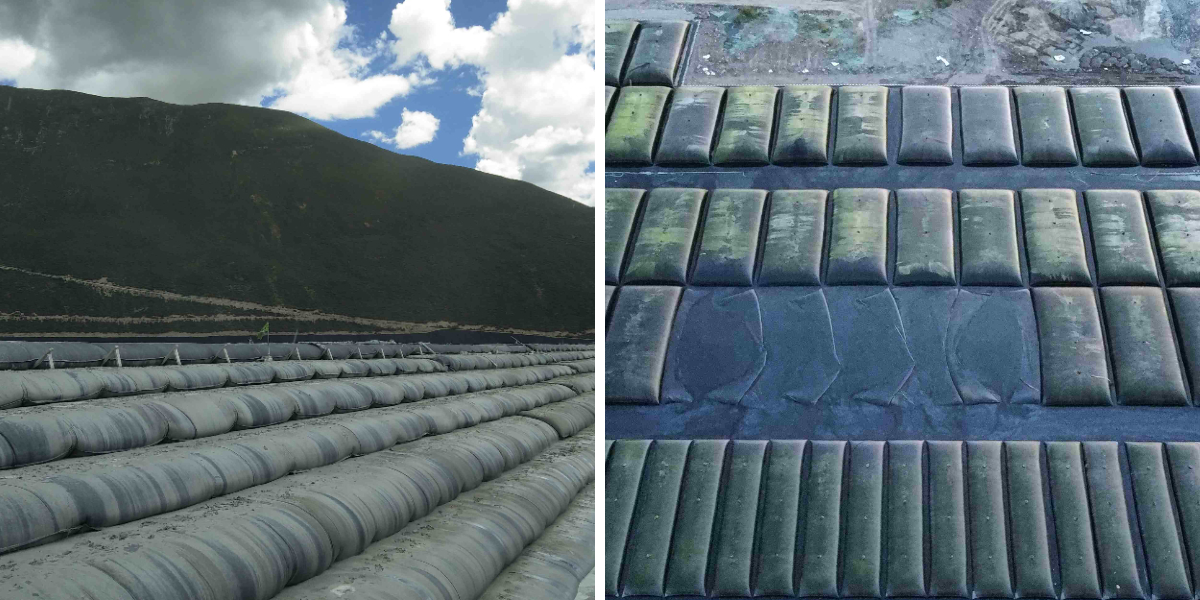

Sediment Filtration Bags is a new type of geosynthetic material structure developed based on polymer synthetic material technology. It is widely used in engineering fields such as water conservancy, environmental protection, and transportation. Its core is to use high-strength and permeable special geotextiles to make tubular or bag shaped containers, and use hydraulic filling technology to fill media such as sediment, sludge, and tailings. After dehydration and consolidation, it forms a structure with specific strength and shape to achieve functions such as solid waste treatment, foundation reinforcement, and protective engineering.

Definition: Core of Structure and Principle

The essence of geotextile bags is a combination of high-strength permeable geotextile containers and hydraulic filling media. Its definition can be broken down from two aspects: "structural composition" and "working principle":

1. Structural composition: The main body is a double-layer or multi-layer composite geotextile, commonly made of materials such as polypropylene (PP), polyester (PET), etc. The tensile strength, corrosion resistance, and permeability are improved through special weaving, needle punching, or coating processes; Both ends or parts of the tube bag are equipped with feeding and exhaust ports, and some parts are also reinforced with ribs or wear-resistant layers to adapt to different engineering environments.

2. Working principle: The prepared "filling medium" such as mud and sand slurry, sludge slurry, etc. is injected into the pipe bag through the feeding port by a high-pressure pump. The water is discharged through the pores of the geotextile, and the solid particles are intercepted and gradually deposited and consolidated in the pipe bag; As the filling amount increases and the dehydration process progresses, the tube bag will expand to the design size (diameter can range from 1 meter to 20 meters, length can reach hundreds of meters), ultimately forming a stable "solid structure" that plays a role in carrying, protecting, or solid waste storage.

Characteristics: Core properties of materials and performance

The characteristics of geotextile bags are determined by their material properties and structural design, and can be summarized into four categories: "high strength, high permeability, strong adaptability, and outstanding environmental protection"

1. Excellent mechanical properties: The tensile strength (radial and latitudinal) of specialized geotextiles can reach over 20kN/m, with strong tear and puncture resistance. They can withstand high pressure during the filling process and self weight loads after consolidation, while also resisting external forces such as water flow erosion and wave impact. They are not easily damaged or deformed during long-term use.

2. Balance between permeability and dewatering efficiency: The porosity of geotextiles is precisely controlled within the range of "allowing water to be quickly discharged while retaining more than 95% of solid particles" (commonly used equivalent pore size O90 is 0.05-0.2mm), and the dewatering cycle after filling is short (usually several days to several weeks), without the need for additional dewatering pipelines, reducing engineering complexity.

3. Strong weather resistance and corrosion resistance: the main materials (PP, PET) have excellent UV resistance and aging resistance, and the performance is stable in the temperature range of -30 ℃ to 60 ℃; Simultaneously resistant to acid and alkali, salt spray, and can be used for a long time in corrosive environments such as seawater, industrial wastewater, and tailings slurry, with a service life of up to 10-20 years.

4. Flexible form and size: the diameter (1-20m), length (10-500m) and shape (round, oval, rectangular) of the pipe bag can be customized according to the project needs, or the large-area structure can be formed by splicing multiple pipe bags to adapt to the space constraints of different sites (such as narrow rivers, irregular mudflat).

5. Outstanding environmental protection: The filling medium can use solid waste such as engineering waste soil, river silt, sewage treatment plant sludge, mining tailings, etc., to achieve "waste treatment with waste" and reduce the amount of solid waste landfill; At the same time, the geotextile itself can be recycled and reused, and there is no chemical pollution during the construction process, which is in line with the concept of green engineering.

Product Parameters:

project | unit | CWGD50S | CWGD90/120 | CWGD90S | CWGD100S | CWGD120S-B | CWGD120S-C | CWGD130S | CWGD200S-C | |

Tensile strength-radial | kN/m | 55 | 90 | 90 | 100 | 130 | 130 | 130 | 220 | |

Tensile strength-Weft | 50 | 120 | 90 | 100 | 120 | 120 | 130 | 210 | ||

Strain elongation-radial | % | 16±1 | 12±1 | 9±1 | 10±1 | 10±1 | 10±1 | 10±1 | 12±1 | |

Extensional elongation-Weft | 10±1 | 8±1 | 8±1 | 8±1 | 8±1 | 8±1 | 8±1 | 8±1 | ||

Breakage strength at 2% elongation | warp direction | kN/m | 5/15 | 14/40 | 30/30 | 30/30 | 20/40 | 22/40 | 20/45 | 15 |

Breakage strength at 5% elongation | warp direction | kN/m | 14/33 | 38/90 | 75/75 | 75/75 | 80/100 | 84/40 | 80/110 | 90 |

mass area ratio | g/m² | 285 | 440 | 390 | 430 | 540 | 540 | 560 | 850 | |

Joint tensile strength | kN/m | 35 | 90 | 60 | 70 | 100 | 100 | 110 | 170 | |

Static Burst Strength (CBR) | KN | 5 | 10 | 10 | 13 | 15 | 15 | 16 | 22 | |

Dynamic perforation | mm | 10 | 8 | 12 | 12 | 10 | 10 | 11 | 8 | |

Equivalent aperture (0g0) | mm | 0.9 | 0.48 | 0.52 | 0.45 | 0.4 | 0.3 | 0.43 | 0.4 | |

Permeability (Q50) | L/m²/s | 200 | 40 | 20 | 15 | 12 | 6.5 | 15 | 15 | |

Ultraviolet resistance (500h strong storage rate ) | % | 90 | 90 | 85 | 85 | 85 | 85 | 85 | 85 | |

Product Applications:

1. Water conservancy and flood control engineering

River channel dredging and sludge disposal: the sludge generated from river channel dredging (with a moisture content of 80% -95%) is injected into the geotechnical pipe bag, and the solid mud cake (with a moisture content of 40% -60%) is formed after dehydration, which can be used for river embankment reinforcement or land reclamation (such as the dredging project in the Taihu Lake Lake basin in Jiangsu Province).

Embankment reinforcement and anti-seepage: Lay geotextile bags on the upstream side of the embankment to form a "bag anti-seepage wall" to resist wave erosion and infiltration damage; Pipe bags can also be filled inside the embankment to enhance the overall bearing capacity of the embankment (such as the reinforcement project of the lower Yellow River embankment).

Temporary water retaining dam: During flood season or emergency rescue, a temporary water retaining dam is formed by quickly filling with soil bags to prevent flood overflow. Compared with sandbags, it has higher water retaining efficiency and stronger stability.

2. Environmental Protection and Solid Waste Treatment Engineering

Sludge disposal in sewage treatment plants: Inject the remaining sludge generated by the sewage treatment plant into a pipe bag, dehydrate it to achieve sludge reduction (volume reduction of more than 60%), and finally carry out sanitary landfill or resource utilization (such as the sludge disposal project of a sewage treatment plant in Shanghai).

Mine tailings treatment: Inject the tailings slurry of metal and non-metal ores into geotextile bags, dehydrate them to form tailings dams, reduce the footprint of tailings ponds, and lower the risk of tailings leakage (such as a copper mine tailings treatment project in Jiangxi).

Landfill anti-seepage: Lay geotextile bags at the bottom of the landfill to form a "composite anti-seepage layer" to prevent leachate from infiltrating and polluting groundwater. At the same time, the bags can serve as a temporary cover layer for the landfill.

3. Transportation and Port Engineering

Soft soil foundation reinforcement: In the construction of soft soil foundations such as highways and airport runways, geotextile bags are filled with sediment and laid on the surface of the foundation to disperse the upper load and reduce foundation settlement through the bearing capacity of the bags (such as soft soil foundation treatment for Zhejiang coastal highways).

Port and waterway protection: In the shore protection engineering of port terminals, geotextile bags are used instead of traditional gabions to form "bag protection" to resist ship collisions and tidal erosion; It can also be used for sediment disposal after channel dredging (such as the Yantian Port Channel Project in Shenzhen).

4. Ecological restoration project

Coastal mudflat restoration: In the degraded coastal mudflat area, fill the geotextile pipe bags to form "artificial sand dam" to prevent seawater erosion. At the same time, the gap between the pipe bags can be planted with mangroves and other salt tolerant plants to promote the ecological restoration of mudflat (such as the Fujian Xiamen Coastal Zone Restoration Project).

Dredging and Restoration of Lakes and Reservoirs: Injecting eutrophic silt from lakes and reservoirs into pipe bags, removing it after dehydration, reducing nitrogen and phosphorus content in water bodies, and improving water quality; Pipe bags can also be used to construct artificial islands and provide habitats for aquatic animals and plants (such as the Yunnan Dianchi Lake dredging and ecological restoration project).

As a new type of geosynthetic material that is "efficient, economical, and environmentally friendly", geotextile bags have the core value of "transforming mobile solid waste into functional structures", which not only solves the problem of solid waste disposal in engineering, but also meets the engineering needs of protection, reinforcement, ecological restoration, etc. With the advancement of polymer material technology and the increasing demand for environmental protection, geotextile bags will have broader application prospects in future water conservancy, environmental protection, and transportation engineering.