Geocell HDPE

1.High strength: The high-density polyethylene material itself has relatively high strength. After being processed by a special process, the tensile strength of the geocell can reach 30 - 50MPa, reaching 1/3 of the strength level of ordinary steel, and it can withstand large loads.

2.Corrosion and Aging Resistance: It has excellent chemical stability, resistance to acid and alkali corrosion, and strong ultraviolet resistance. Under different environmental conditions, such as humid, saline - alkaline, high - temperature or cold environments, it can maintain good performance, has a long service life. Generally, the durability after ultraviolet stabilization treatment can exceed a 30 - year service cycle.

3.Good water permeability: The geocell itself has certain pores that allow water to pass through, which is beneficial for the drainage of water in the soil. This helps to avoid the softening and gradual damage of the roadbed caused by waterlogging. At the same time, it also contributes to the growth and development of plant roots.

4.Light weight: The density is controlled within the range of 0.9 - 1.2t/m³. Compared with traditional filling materials such as crushed stone and concrete, the self-weight is significantly reduced, approximately half of theirs. This not only reduces the transportation cost but also decreases the settlement risk caused by the structural self-weight.

Product Introduction:

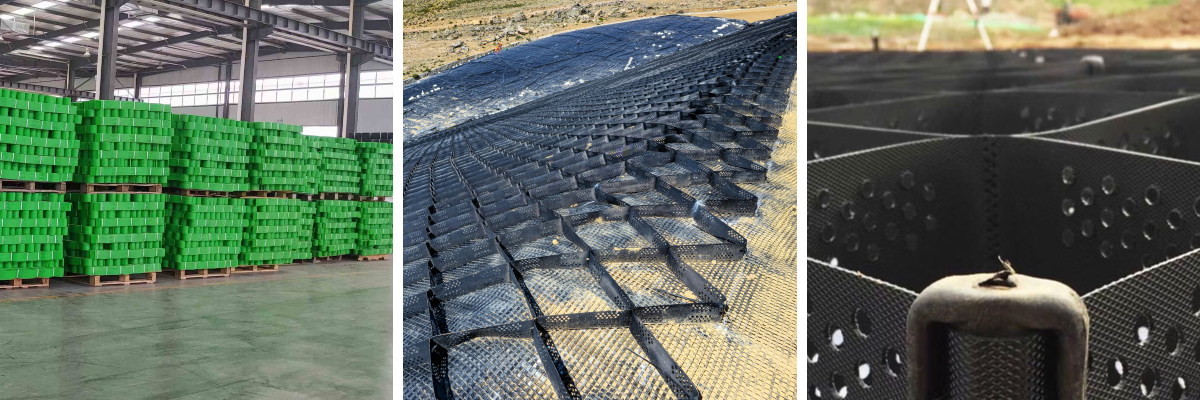

Geocell HDPE is a geosynthetic material made of high - strength high - density polyethylene (HDPE) material. Geocell Hdpe plays an important role in multiple engineering fields due to its unique structure and material properties.

Structural Features

Honeycomb - like Three - dimensional Grid Structure: The geocell is formed into a honeycomb - like three - dimensional grid system by strip - shaped high - density polyethylene materials through processes such as ultrasonic welding. This structure achieves geometric optimization of stress distribution within a unit volume. A stable angle of 45 - 60° is formed between the walls of each unit. When subjected to vertical loads, the pressure can be decomposed into radial and tangential components through tensile stress, effectively suppressing the lateral displacement of soil particles.

Scalability: The geocell has the characteristic of being able to expand and contract freely. During transportation, it can be compressed and folded to reduce its volume, facilitating transportation and storage. When in use, it can be unfolded and fixed to adapt to different terrains and construction requirements.

Product Parameters:

order number | raw and processed material | |||||||

test item | unit | polytene | sulan | polyester | ||||

Extruded type | Stretch type | Extruded type | Stretch type | Extruded type | Stretch type | |||

1 | tensile strength | kN/m | ≥20 | ≥100 | ≥23 | ≥100 | ≥30 | ≥120 |

2 | Tensile yield strain | % | ≤15 | — | ≤15 | — | ≤15 | - |

3 | Tensile fracture strain | % | — | 8~ 20 | — | 6~ 15 | — | 8~ 20 |

4 | Carbon black content a | % | 2. 0~ 3. 0 | |||||

5 | Carbon black dispersion a | — | There should be no more than one level 3 data item in ten data items and no level 4 or 5 data items | |||||

6 | 200℃ oxidation induction time | min | ≥20 | ≥20 | — | |||

7 | Tensile load stress cracking | h | ≥300 | — | ||||

8 | B. Resistance to artificial climate aging retention rateb | % | ≥80 | |||||

9 | Chemical resistance performance retention rate c | % | — | ≥80 | ||||

Product Applications:

1.Road and Traffic Engineering

Subgrade Reinforcement

Application Scenarios: Applicable to the subgrade construction of newly built highways and railways, especially in adverse geological sections such as soft soil foundations and collapsible loess.

Principle of action: Through the lateral restraint and stress diffusion effects of the cell, the subgrade load is evenly distributed to a larger area of foundation soil, reducing subgrade settlement (the settlement can be reduced by more than 40%), and improving the bearing capacity of the subgrade (the bearing capacity can be increased by 2 - 3 times) and the anti - deformation ability.

Typical cases: In the construction of desert roads, the cell can fix sand grains and prevent the subgrade from being eroded by wind and sand; in permafrost areas, it can reduce the damage to the subgrade caused by freeze - thaw cycles.

Treatment of Pavement Base

Application Scenarios: Used as a base reinforcement material for asphalt or concrete pavements.

Functions: Inhibits the generation and expansion of pavement cracks, extends the service life of the pavement, and is especially suitable for heavy - traffic roads (such as roads in industrial parks, port terminals).

2.Slope Protection and Ecological Engineering

Slope Soil Stabilization and Landslide Prevention

Application Scenarios: Highway and railway slopes, mine slopes, reservoir dam slopes, etc.

Function: After the cellular confinement system is unfolded, it is fixed on the slope surface, filled with soil and planted with vegetation to form a composite protection system of "cellular confinement system + vegetation".

The three-dimensional structure of the cellular confinement system can prevent the soil from sliding down, and the anti - slide stability safety factor can be increased by more than 30%;

The roots of the vegetation interweave with the cellular confinement system, enhancing the ecological stability of the slope and beautifying the environment at the same time (such as the landscape slopes of highways).

Eco - restoration and Greening

Application Scenarios: Ecological restoration projects such as rocky slopes, mine wasteland, riverbank revetments, etc.

Advantages: The cellular confinement system provides growth space for soil and plant roots. Even on steep slopes (with a slope gradient of over 60°), vegetation coverage can be achieved, promoting soil and water conservation and the reconstruction of the ecosystem.

3.Water Conservancy and River Channel Governance

River Channel and Dam Protection

Application Scenarios: Slope protection projects for riverbanks, lakeshores, and reservoir dams.

Functions: After filling the honeycombs with crushed stones or soil, it can resist water flow scouring (the anti - scouring flow velocity can reach 4 - 6m/s), reduce soil erosion, and at the same time maintain the material exchange between water bodies and soil, thus maintaining the ecological environment of the river channel.

Flood Control and Soil and Water Conservation

Application Scenarios: Reinforcement of flood control dikes in flood - prone areas, treatment of gullies and washouts.

Case: In the treatment of gullies on the Loess Plateau, the cellular confinement system can fix the soil on the gully slopes and prevent the formation of new gullies caused by heavy rain scouring.

4.Special Engineering and Foundation Treatment

Desert and Tidal Flat Foundation Treatment

Application Scenarios: Temporary roads in desert areas, foundations of oilfield operation areas, and engineering construction on coastal tidal flats.

Functions: After filling the cellular confinement system with sand grains or crushed stones, a stable bearing layer is formed to solve the problems of easy fluidity of desert foundations and softness of tidal flat foundations, improving the construction feasibility.

Landfills and Tailings Dams

Application Scenarios: Reinforcement of the base of landfills and slope stability of mine tailings dams.

Advantages: Enhance the integrity of the foundation, prevent lateral displacement and settlement of landfilled materials or tailings. At the same time, when used in conjunction with the anti-seepage layer, it improves the engineering safety.

5.Other application fields

Retaining walls and supporting structures

Used as a reinforcing material for light - weight retaining walls to reduce the self - weight of the wall and foundation pressure, and lower the project cost.

Parking lots and square ground

After laying the cell, fill it with crushed stones or plant grass to form an ecological parking lot, which has both bearing capacity and greening effect.

Airport Runways and Yards

Reinforce the foundation of airport runways to improve fatigue resistance; used in industrial yards (such as coal yards and material yards) to prevent foundation settlement and material loss.

The versatility of high - density polyethylene geocells makes it an efficient "flexible structure" solution in geotechnical engineering, especially in scenarios where both engineering strength and ecological benefits need to be considered, it has significant advantages.