Instant Concrete Mat

1.Ultra-Fast Construction

Simply unroll, water, and hardens in 24 hours, saving 90% time.

2.Lightweight & Flexible

Rollable and cuttable, adapts to complex terrain, easy to transport.

3.High Strength & Durability

Hardened for compression resistance, waterproof, fireproof, lifespan equals concrete.

4.Eco-Friendly & Efficient

Minimizes material waste, 95% lower carbon emissions, no heavy machinery needed.

5.Wide Applications

Ideal for engineering reinforcement, disaster relief, waterproofing, and more.

Product Introduction:

Instant Concrete Mat, also known as Concrete Canvas or Cement Blanket, is a revolutionary flexible composite material. It is composed of two layers of high-strength geotextiles encapsulating precisely proportioned dry-mix cement and special additives.

Material Properties

1.Flexible and Malleable

When dry, Concrete Cloth resembles a soft fabric and can be freely cut, folded, or rolled, adapting to complex terrains and irregular structures. Upon hydration, the cement-based material undergoes a chemical reaction, gradually hardening into a rigid concrete layer with a typical thickness of 3–10 mm.

2.Rapid Hardening

After watering, Concrete Cloth begins to harden within 2–4 hours, reaching 80% of its design strength within 24 hours and fully curing in 7 days. The hardened strength ranges from C20 to C40, meeting the requirements of general engineering applications.

3.Waterproof and Fire-Resistant

The surface of Concrete Cloth is coated with a waterproof layer, forming a dense structure upon hardening that effectively blocks water penetration. Additionally, the material achieves Class A fire resistance and withstands temperatures exceeding 800°C.

4.Corrosion-Resistant and Aging-Resistant

Concrete Cloth exhibits excellent resistance to acids, alkalis, salts, and other chemicals, making it suitable for harsh environments. It has a service life of over 50 years and requires no special maintenance.

5.Lightweight yet High-Strength

Weighing only 10–15 kg per square meter, Concrete Cloth is just 1/10 the weight of traditional concrete. Despite its lightweight nature, its hardened strength is comparable to that of ordinary concrete, facilitating easy transportation and construction.

Core Structure: The inner layer is a mixture of special cement, aggregates and fibers; the outer layer is a breathable and waterproof high-strength polyester or polypropylene geotextile, with interlocking structures on the edges for easy splicing.

Working Principle: After on-site laying, it only needs to be watered to activate the hydration reaction. No on-site concrete mixing is required. It can harden and form within 24 hours, and reach the designed strength in 7 days.

Product Form: Supplied in rolls, with standard width of 1–2m, length of 5–10m and thickness of 5–50mm. Custom specifications are available according to project requirements.

Storage Characteristics: Can be stored for a long time in dry environments before activation, with a shelf life of 12 months under standard storage conditions.

Product Parameters:

<col width="100%" style="width:78.60pt;span="2"/>

| Property | State | 8mm | 10mm | 12mm | 15mm | Test Method | |

| Compressive strength(MPa) | cured 28 days | 60 MPa | D8329 | ||||

| Flexural strength(MPa) | cured 28 days | 15 MPa | D8058 | ||||

| Pyramid puncture(kN) | cured 28 days | 4.0 kN | 4.5 kN | 5.0 kN | 6.0 kN | D5494,Type B | |

| Abrasion (maximum value) | cured 28 days | 0.3 mm/1000 cycles | C1353/C1353M | ||||

| Tensile strength | Final | uncured | 20 kN/m | 30 kN/m | 35 kN/m | 40 kN/m | D6768/D6768M |

| Initial | cured 28 days | 15 kN/m | 25 kN/m | 30 kN/m | 35 kN/m | D4885 | |

| Final | 25 kN/m | 35 kN/m | 40 kN/m | 45 kN/m | |||

| Freeze-thaw | Residual initial flexural strenath(D8058) | cured 28 days, 200 cycles | >80 % (Pass) | C1185 | |||

| Water quality requirements for hydration | Tap water、River water、Seawater | / | |||||

| Construction temperature conditions | Construction above 0℃ | ||||||

| Fire protecting performance | B1 | GB 8624-2012 | |||||

| Harmful substance leaching test items | Limitation index (mg/L) | GB 5085.3-2007 | |||||

| Copper (total copper) (mg/L) | ≤100 | ||||||

| Zinc (total zinc) (mg/L) | ≤100 | ||||||

| Cadmium (total) (mg/L) | ≤1 | ||||||

| Lead (total lead) (mg/L) | ≤5 | ||||||

| Total chromium (mg/L) | ≤15 | ||||||

| Nickel (total nickel) | ≤5 | ||||||

| Arsenic (total) | ≤5 | ||||||

Product Advantages:

Ultra-efficient Construction: Eliminates the need for on-site mixing, transporting and pouring of concrete. The mat can be directly laid, spliced and watered, reducing construction time by 60%–80% compared with traditional concrete.

Cost Reduction: Saves labor costs, equipment rental fees and material waste. No need for complex formwork support, which cuts the overall project cost by 30%–50%.

Strong Adaptability: Flexible enough to fit irregular surfaces such as slopes, ditches and curved structures, realizing seamless coverage and avoiding leakage points.

Environmental Friendliness: The dry-mix formula is pre-proportioned, with no dust pollution during construction. The geotextile shell can effectively prevent soil erosion and improve the ecological environment of the project area.

Long-term Durability: After curing, it has high compressive strength, excellent impermeability, corrosion resistance and weather resistance, with a service life of more than 50 years under normal use conditions.

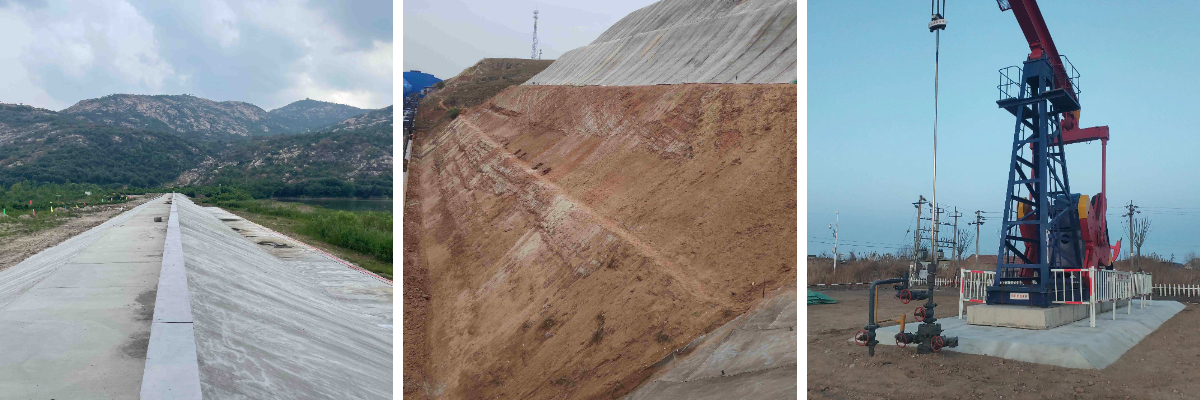

Product Applications:

Water Conservancy Engineering: Canal lining, reservoir anti-seepage, dam reinforcement, slope protection of river banks and ditches.

Transportation Engineering: Roadbed reinforcement, slope protection of highways and railways, culvert lining, and pavement repair of rural roads.

Municipal Engineering: Sewage treatment tank lining, landfill anti-seepage, rainwater collection ditch construction, and green belt water retention projects.

Emergency and Disaster Relief Projects: Emergency repair of damaged embankments, temporary flood control dikes, quick repair of roads and bridges after disasters.

Industrial and Mining Engineering: Tailings pond anti-seepage, foundation reinforcement of industrial plants, and slope protection of mining areas.

Contact Us

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province