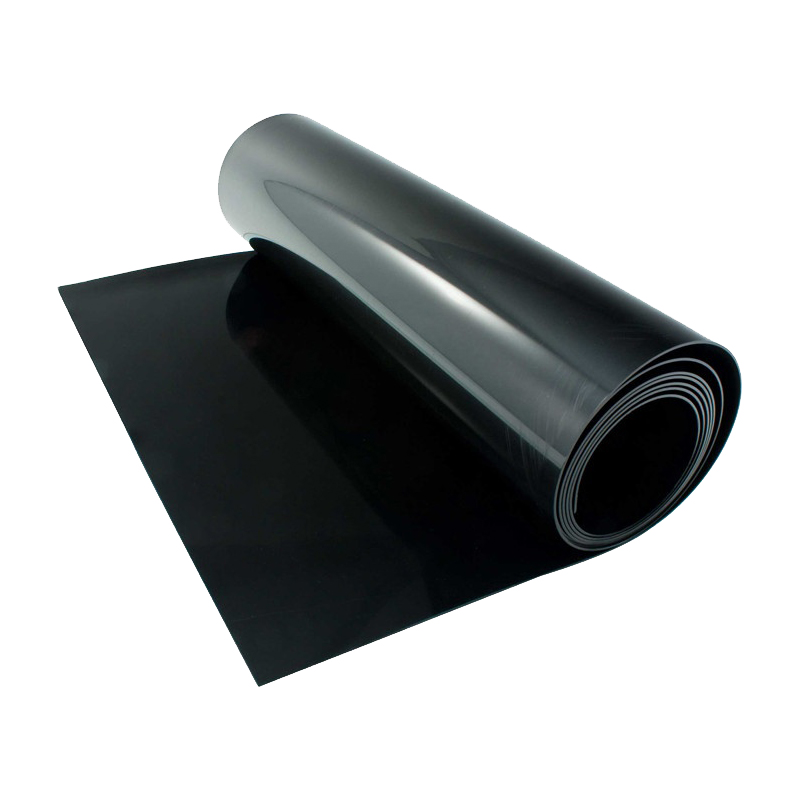

Geo Membrane Sheet

1.High Barrier Performance:

Manufactured from materials such as HDPE (High-Density Polyethylene) and LLDPE (Linear Low-Density Polyethylene), geomembranes exhibit extremely low permeability coefficients (typically ≤10⁻¹³ cm/s), effectively blocking water, oil, gases, and harmful chemicals.

2.Organic Solvent Resistance:

Stable against most organic solvents (e.g., oils, alcohols), preventing material degradation.

3.Tensile and Tear Resistance:

Reinforced with additives like carbon black, geomembranes offer high mechanical strength (e.g., tensile break strength up to 20 MPa), ensuring load-bearing capacity during installation and operation.

Product Introduction:

Geo Membrane Sheet is high-performance waterproof barrier materials made from high-molecular polymers such as HDPE (High-Density Polyethylene), LDPE (Low-Density Polyethylene), LLDPE (Linear Low-Density Polyethylene), PVC (Polyvinyl Chloride), and EVA (Ethylene-Vinyl Acetate). Through advanced extrusion or blow molding processes, they form a flexible, durable, and impermeable membrane widely used in environmental protection, water conservancy, agriculture, mining, and civil engineering projects.

Feature

1.Excellent Anti - Seepage Performance

It has a low permeability coefficient, which enables it to effectively prevent liquid leakage.

2.Good Chemical Corrosion Resistance

It exhibits excellent resistance to erosion by acids, alkalis, salts, and other chemical substances.

3.Excellent Aging Resistance

When used in a light - shielded environment, it has a long service life.

4.Strong Adaptability to Deformation

With good elongation properties, it can withstand a certain degree of deformation.

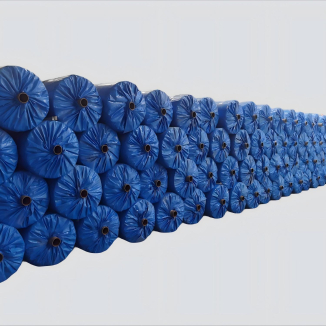

5.Convenient Construction

It is lightweight, making it easy to transport and lay.

Product Parameters:

| Metric | ASTM | unit | Test value | Minimum test frequency | ||||||

| test method | 0.75 mm | 1.00 mm | 1.25 mm | 1.50 mm | 2.00 mm | 2.50mm | 3.00 mm | |||

| Minimum average thickness | D5199 | mm | 0.75 | 1 | 1.25 | 1.5 | 2 | 2.5 | 3 | Per volume |

| Minimum value (any one of 10) | -10% | -10% | -10% | -10% | -10% | -10% | -10% | |||

| minimum density | D 1505/D 792 | g/cm3 | 0.94 | 0.94 | 0.94 | 0.94 | 0.94 | 0.94 | 0.94 | 90,000 kg |

| Minimum average tensile performance (1) | D638 Type IV | |||||||||

| Breakage strength, | N/mm | 20 | 27 | 33 | 40 | 53 | 67 | 80 | 9,000 kg | |

| yield strength | N/mm | 11 | 15 | 18 | 22 | 29 | 37 | 44 | ||

| Strain extension, | % | 700 | 700 | 700 | 700 | 700 | 700 | 700 | ||

| yield extension | % | 12 | 12 | 12 | 12 | 12 | 12 | 12 | ||

| Minimum strength of right-angle tear | D 1004 | N | 93 | 125 | 156 | 187 | 249 | 311 | 374 | 20,000 kg |

| Minimum puncture strength | D4833 | N | 240 | 320 | 400 | 480 | 640 | 800 | 960 | 20,000 kg |

| Constant tensile load stress cracking (2) | D5397 | hour | 300 | 300 | 300 | 300 | 300 | 300 | 300 | Based on GRI GM-10 |

| Carbon black content | D 1603(3) | % | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 9,000 kg |

| Carbon black dispersion | D5596 | Note (4) | Note (4) | Note (4) | Note (4) | Note (4) | Note (4) | Note (4) | 20,000 kg | |

| Oxygen induction time (OIT) (5) | 90,000 kg | |||||||||

| (a) Standard OIT | D3895 | minute | 100 | 100 | 100 | 100 | 100 | 100 | 100 | |

| (b) high-handed OIT | D5885 | minute | 400 | 400 | 400 | 400 | 400 | 400 | 400 | |

| 85℃ Oven aging (minimum average) (5)(6) | Per formula | |||||||||

| (A) Standard OIT is retained after 90 days | D 5721 | % | 55 | 55 | 55 | 55 | 55 | 55 | 55 | |

| (B) High voltage OIT is retained for 90 days | D 3895 D5885 | % | 80 | 80 | 80 | 80 | 80 | 80 | 80 | |

| Ultraviolet resistance (7) | Per formula | |||||||||

| (a) standard OIT | D3895 | Note (8) 50 | ||||||||

| (b) Retention of high pressure OIT after 1600 hours (9) | D5885 | % | ||||||||

Product Applications:

1.Environmental Protection Projects:

Anti-seepage liners for landfills, barrier layers for hazardous waste treatment ponds to prevent leachate from polluting groundwater; blocking methane gas leakage in biogas projects.

2.Water Conservancy and Hydropower:

Anti-seepage for reservoir dams, ecological revetment for rivers, and linings for water storage tanks.

3.Agriculture and Ecology:

Anti-seepage for fish ponds, saline-alkali land improvement, and water purification systems for constructed wetlands.

4.Municipal Engineering and Transportation:

Waterproofing for metro tunnels, moisture protection for underground utility corridors, and anti-seepage drainage for highway slopes.