Geotextile Behind Retaining Wall

1. Anti filtration and anti instability: Backfill soil fine particles behind the retaining wall to prevent soil loss with water, avoid internal voids in the wall, and allow water to be smoothly discharged, reducing pore water pressure and preventing pipe surges to maintain stability.

2. Reinforcement to resist lateral pressure: Enhance the integrity of backfill soil, disperse lateral pressure on the soil, reduce the sliding and overturning of retaining walls caused by excessive pressure, and adapt to complex scenarios such as high fill.

3. Isolation and Loss Reduction: Separate the wall from the backfill material to avoid sharp particles from damaging the wall; Simultaneously isolate soils of different gradations to prevent material mixing from affecting drainage and load-bearing capacity, and extend the lifespan of the wall.

4. Adaptable and easy to lay: The material is flexible and can be cut according to the contour of the retaining wall, fitting the base layer behind the curved or folded wall, without the need for complex equipment, and can be quickly constructed to reduce costs.

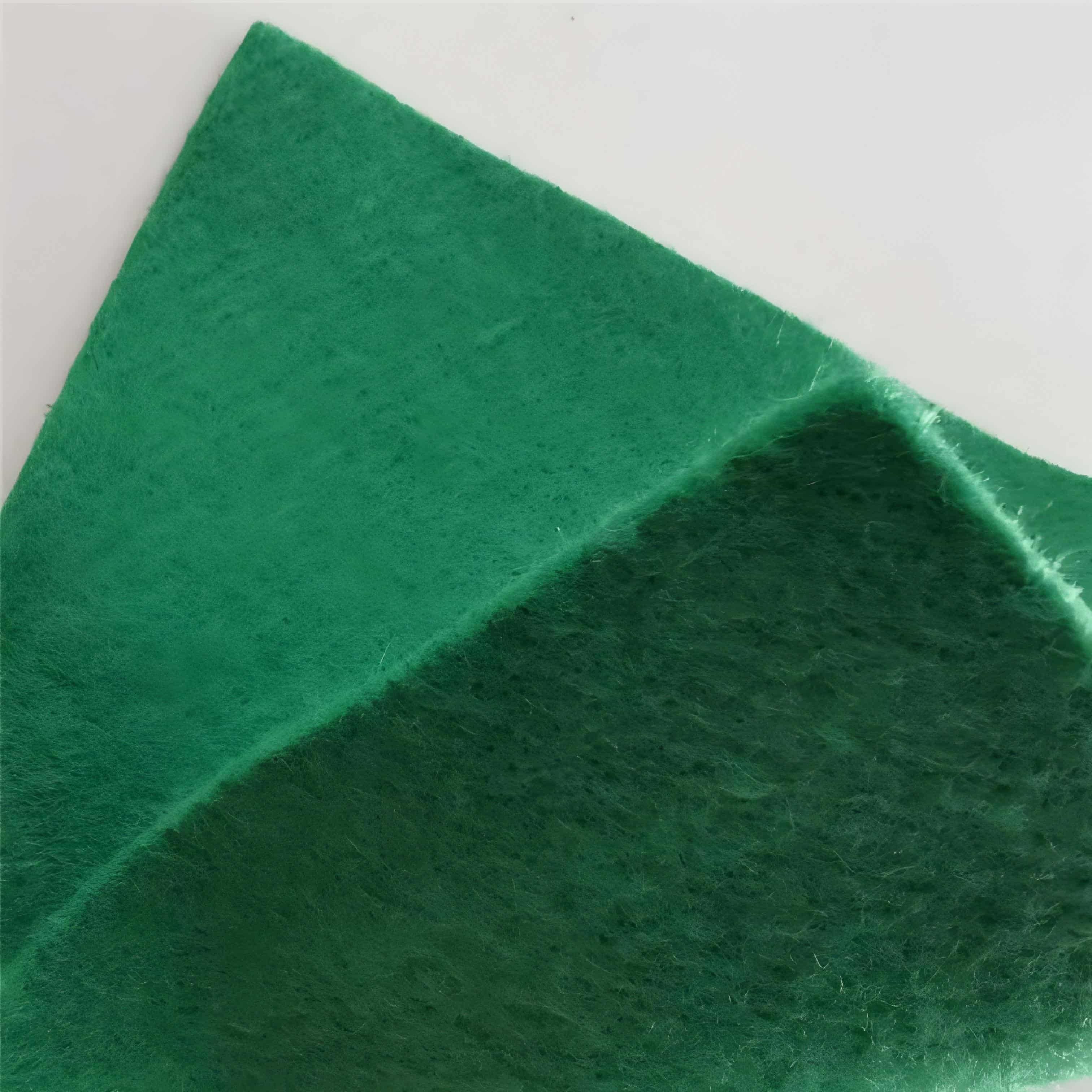

Products Introduction:

Geotextile Behind Retaining Wall is a functional geosynthetic material designed specifically for the backfill area behind retaining walls. It is made from high-strength polypropylene (PP) or polyester (PET) and processed through needle punched non-woven or machine weaving techniques. Some products are additionally treated with UV resistance and acid alkali corrosion resistance. Its core application scenario is to be laid between the main body of the retaining wall and the backfill soil behind it, undertaking three core functions of anti filtration and drainage, reinforcement and soil stabilization, and isolation and protection. It solves key problems such as "soil loss causing voids, water accumulation and pressure increasing causing overturning, and material wear and tear causing damage" behind the retaining wall, providing guarantees for the stability of the rear structure of various types of retaining walls such as gravity, cantilever, and ecological, and is an important supporting material to ensure the long-term safe service of retaining walls.

Product Features:

1. Dual effect of anti filtration and drainage, anti instability and anti pipe surge: The fabric pores are precisely matched with the particle size distribution of the backfill soil behind the retaining wall, which can efficiently filter out fine particles (clay, silt) in the backfill soil, prevent them from flowing away with rainwater or groundwater, and avoid the formation of voids behind the retaining wall that may cause wall settlement; It can also quickly guide the infiltration and discharge of water, reduce the pore water pressure of backfill soil, prevent the phenomenon of "pipe surge" from the root, and reduce the impact of lateral pressure caused by accumulated water on the wall.

2. Directional reinforcement and soil stabilization, anti slip and anti overturning: It has excellent longitudinal and transverse tensile strength (25-70kN/m), and after laying, it is closely combined with the backfill soil behind it to form a "soil cloth composite system", which can enhance the overall shear resistance of the backfill soil, disperse the lateral thrust of the soil, effectively resist the risk of sliding and overturning of the retaining wall caused by excessive soil pressure behind it, especially suitable for complex stress scenarios behind retaining walls such as high fill and soft soil foundations.

3. Durable isolation and protection, reducing damage and prolonging life: On the one hand, it can isolate the main body of the retaining wall (such as concrete walls, stone walls) from the backfill material behind, avoiding sharp gravel and hard blocks from directly rubbing and hitting the wall surface, reducing the wear and tear of the wall structure; On the other hand, different levels of backfill soil (such as sand and clay layers) can be separated to prevent material mixing from causing poor drainage or reduced bearing capacity, thereby extending the overall service life of the system behind the retaining wall.

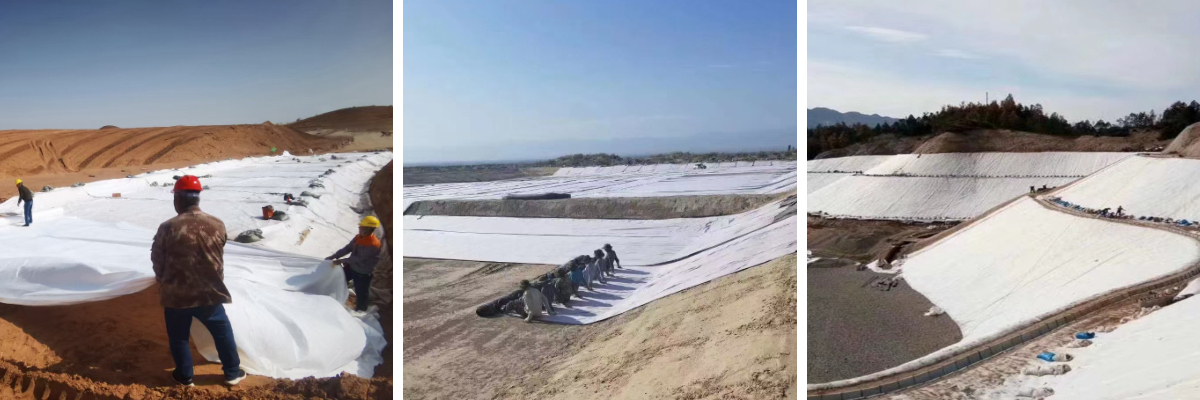

4. Suitable for the scene and easy to construct, reducing costs and improving efficiency: with flexible texture and light weight (unit area mass 100-400g/m ²), it can be flexibly cut and spliced according to the contour behind the retaining wall (such as curved wall surface, stepped backfill area), without the need for professional heavy equipment; When laying, it can closely adhere to the base layer behind the wall without wrinkles or hollows, and is suitable for various construction environments behind retaining walls. Compared with traditional protection methods, it can shorten the construction period by about 25% and reduce labor and material loss costs.

Product Parameters:

project | metric | ||||||||||

Nominal strength/(kN/m) | |||||||||||

6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |||

1 | Longitudinal and transverse tensile strength / (kN/m) ≥ | 6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |

2 | Maximum elongation at maximum load in longitudinal and transverse directions/% | 30~80 | |||||||||

3 | CBR top penetration strength /kN ≥ | 0.9 | 1.6 | 1.9 | 2.9 | 3.9 | 5.3 | 6.4 | 7.9 | 8.5 | |

4 | Longitudinal and transverse tearing strength /kN | 0.15 | 0.22 | 0.29 | 0.43 | 0.57 | 0.71 | 0.83 | 1.1 | 1.25 | |

5 | Equivalent aperture O.90(O95)/mm | 0.05~0.30 | |||||||||

6 | Vertical permeability coefficient/(cm/s) | K× (10-¹~10-), where K=1.0~9.9 | |||||||||

7 | Width deviation rate /% ≥ | -0.5 | |||||||||

8 | Unit area mass deviation rate /% ≥ | -5 | |||||||||

9 | Thickness deviation rate /% ≥ | -10 | |||||||||

10 | Thickness coefficient of variation (CV)/% ≤ | 10 | |||||||||

11 | Dynamic perforation | Puncture hole diameter/mm ≤ | 37 | 33 | 27 | 20 | 17 | 14 | 11 | 9 | 7 |

12 | Longitudinal and transverse fracture strength (grab method)/kN ≥ | 0.3 | 0.5 | 0.7 | 1.1 | 1.4 | 1.9 | 2.4 | 3 | 3.5 | |

13 | Ultraviolet resistance (Xenon arc lamp method) | Longitudinal and transverse strength retention rate% ≥ | 70 | ||||||||

14 | Ultraviolet resistance (fluorescence UV lamp method) | Longitudinal and transverse strength retention rate% ≥ | 80 | ||||||||

Product Applications:

1. Behind gravity retaining walls: Located behind masonry/concrete gravity retaining walls such as municipal road slopes and community walls, it is laid between the wall and backfill soil to prevent soil erosion through anti filtration function. At the same time, it disperses lateral pressure with reinforcement performance, avoiding cracks and tilting of the wall due to long-term pressure. It is especially suitable for rainy areas to prevent water accumulation and pressure increase in the rear.

2. Behind cantilevered/buttressed retaining walls: In large parking lots and industrial parks, reinforced concrete cantilevered/buttressed retaining walls are mainly laid at the toe, heel, and backfill layer areas to isolate the backfill soil from the wall foundation, prevent fine particles from blocking the foundation drainage holes, protect the wall reinforcement from soil corrosion, enhance the stability of the backfill soil behind, and reduce the stress burden on the cantilevered structure of the wall.

3. Behind the ecological retaining wall: behind the grass planted concrete and ecological gabion retaining wall in urban rivers and wetland parks, it is laid between the ecological materials and backfill soil, which not only ensures soil stability through anti filtration function, but also prevents soil erosion from affecting vegetation root growth; It can also prevent fine soil from blocking the pores of ecological materials, maintain the permeability function behind the retaining wall, and balance ecological and structural stability.

4. Behind temporary retaining walls: Laying this geotextile behind temporary retaining walls (such as steel sheet piles, sandbag retaining walls) for building foundation pits, road repairs, etc. can quickly form a temporary anti filter protection system to prevent soil erosion from causing foundation pit collapse and road settlement, ensuring the safety of temporary engineering construction. The construction is convenient, low-cost, and meets the short-term and efficient protection needs of temporary engineering.

Geotextile Behind Retaining Wall focuses on the core scenario of "behind retaining walls", with four core advantages of "anti filtration and drainage, reinforced soil stabilization, isolation and protection, and easy construction", to accurately solve the structural stability and durability pain points of engineering behind retaining walls. It can not only provide a triple guarantee of "anti loss, anti water accumulation, and anti wear" for the system behind the retaining wall, but also adapt to various types of retaining walls and construction environments, balancing functionality and economy. Whether it is permanent municipal, ecological retaining walls, or temporary engineering retaining walls, this product can provide reliable support for the safety behind the retaining wall through scientific performance design, reduce engineering hazards, and lower maintenance costs. It is a key supporting material for improving the overall engineering quality of retaining walls.