Geotech Fabric for Retaining Walls

1. Strong reinforcement and anti slip: Enhance the integrity of retaining walls and backfill soil, disperse lateral soil pressure, reduce the risk of wall sliding and overturning, and improve structural stability.

2. Precise anti filtration and anti pipe surge: Filter fine particles in backfill soil, allow water to permeate and be discharged, avoid soil loss causing wall voids and settlement, and ensure smooth drainage.

3. Isolation and protection to reduce wear and tear: Separate different backfill materials (such as sand and clay) to prevent material mixing; At the same time, it protects the wall from sharp particle wear and extends its service life.

4. Strong adaptability and easy construction: The material is easy to cut and can be laid according to the irregular contour of retaining walls. It is suitable for various types of walls such as gravity and cantilever, shortening the construction period.

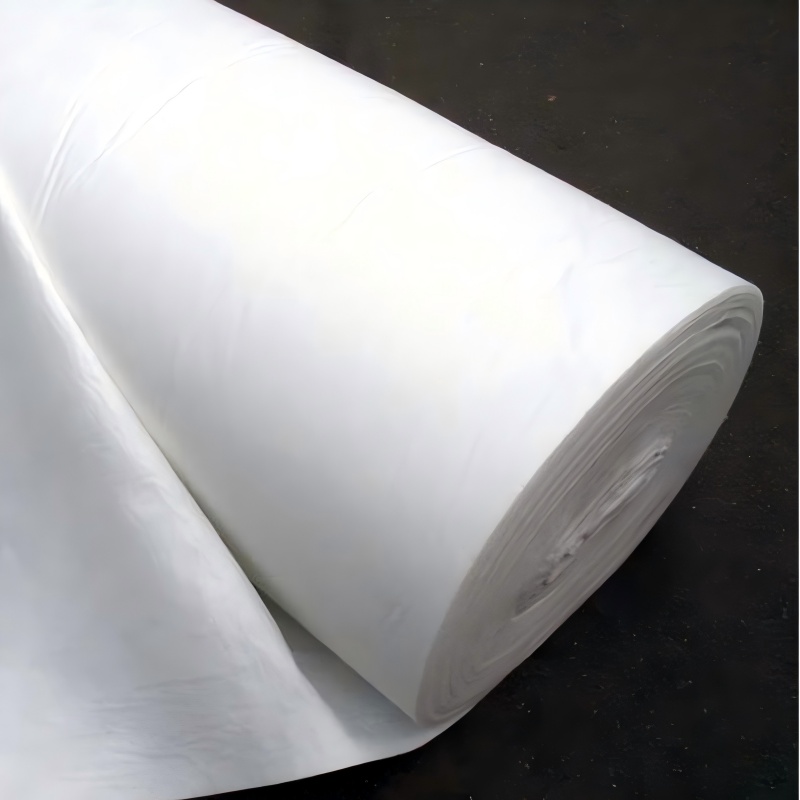

Products Introduction:

Geotextile for Retaining Walls is a high-performance geosynthetic material specially designed for retaining wall engineering. It is made of high-strength polypropylene (PP) or polyester (PET) as raw materials through needle (non-woven) or woven processes. Some products will also undergo special anti-aging and anti-corrosion treatment. Its core function is to undertake the four major functions of reinforcement, filtration, isolation, and protection between the retaining wall and backfill soil, or in the layered structure of backfill soil. It solves the pain points of "excessive lateral pressure, soil erosion, drainage blockage, and material wear" in retaining wall engineering, and provides structural stability guarantee for various types of retaining walls such as gravity type, cantilever type, and reinforced soil type. It is a key supporting material for improving the bearing capacity and service life of retaining walls.

Product Features:

1. High strength reinforcement, anti lateral pressure and anti overturning: using filament weaving or high-density needle punching technology, the longitudinal/transverse tensile strength can reach 30-80kN/m, and the tear resistance is excellent. After laying, it can form a "composite structure" with backfill soil, effectively dispersing the lateral soil pressure borne by the retaining wall, reducing the sliding, overturning or cracking of the wall caused by uneven pressure, especially suitable for complex retaining wall scenarios such as high fill and soft soil foundation.

2. Precise anti filtration, anti surge and stable: The fabric pores are scientifically designed to filter fine particles (such as clay and silt) in the backfill soil, preventing them from losing moisture and avoiding the formation of voids inside the retaining wall, which can cause structural settlement; It can also allow rainwater and groundwater to smoothly infiltrate and discharge, reduce the pore water pressure of backfill soil, prevent "pipe surge" phenomenon, and ensure the long-term stability of retaining walls.

3. Isolation and protection, prolonging life and reducing losses: It can effectively separate the main body of the retaining wall (such as concrete and stones) from the backfill material, avoiding sharp crushed stones and hard blocks from directly wearing down the wall surface and reducing structural losses of the wall; Simultaneously isolate backfill soil of different gradations (such as sand layers and clay layers) to prevent material mixing from causing poor drainage or reduced bearing capacity, and extend the overall service life of the retaining wall.

4. High adaptability and easy construction, cost reduction and efficiency improvement: The material is flexible and lightweight, and can be cut and spliced freely according to the contour of the retaining wall (such as arc and line shapes), without the need for professional and complex equipment; Suitable for various types of retaining walls such as gravity type, cantilever type, and reinforced soil type, it can quickly fit the base layer and reduce construction processes. Compared with traditional protective materials, it can shorten the construction period by about 30% and reduce labor costs.

Product Parameters:

project | metric | ||||||||||

Nominal strength/(kN/m) | |||||||||||

6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |||

1 | Longitudinal and transverse tensile strength / (kN/m) ≥ | 6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |

2 | Maximum elongation at maximum load in longitudinal and transverse directions/% | 30~80 | |||||||||

3 | CBR top penetration strength /kN ≥ | 0.9 | 1.6 | 1.9 | 2.9 | 3.9 | 5.3 | 6.4 | 7.9 | 8.5 | |

4 | Longitudinal and transverse tearing strength /kN | 0.15 | 0.22 | 0.29 | 0.43 | 0.57 | 0.71 | 0.83 | 1.1 | 1.25 | |

5 | Equivalent aperture O.90(O95)/mm | 0.05~0.30 | |||||||||

6 | Vertical permeability coefficient/(cm/s) | K× (10-¹~10-), where K=1.0~9.9 | |||||||||

7 | Width deviation rate /% ≥ | -0.5 | |||||||||

8 | Unit area mass deviation rate /% ≥ | -5 | |||||||||

9 | Thickness deviation rate /% ≥ | -10 | |||||||||

10 | Thickness coefficient of variation (CV)/% ≤ | 10 | |||||||||

11 | Dynamic perforation | Puncture hole diameter/mm ≤ | 37 | 33 | 27 | 20 | 17 | 14 | 11 | 9 | 7 |

12 | Longitudinal and transverse fracture strength (grab method)/kN ≥ | 0.3 | 0.5 | 0.7 | 1.1 | 1.4 | 1.9 | 2.4 | 3 | 3.5 | |

13 | Ultraviolet resistance (Xenon arc lamp method) | Longitudinal and transverse strength retention rate% ≥ | 70 | ||||||||

14 | Ultraviolet resistance (fluorescence UV lamp method) | Longitudinal and transverse strength retention rate% ≥ | 80 | ||||||||

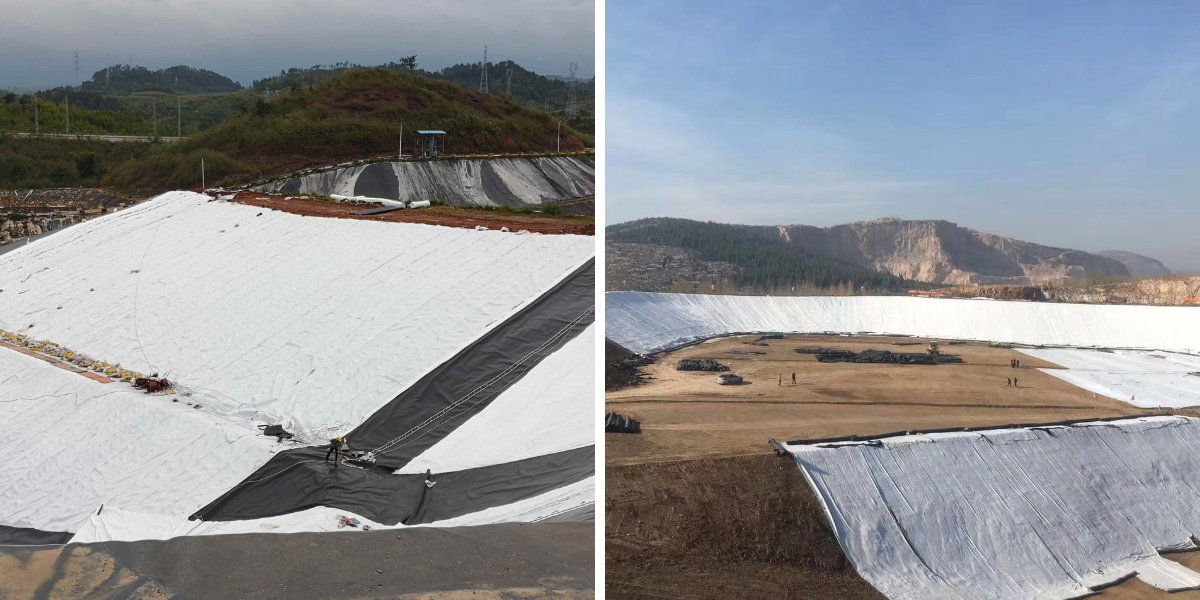

Product Applications:

1. Gravity retaining wall engineering: In gravity retaining walls made of bricks, stones, and concrete (commonly found on municipal road slopes and community walls), they are laid between the wall and backfill soil to prevent soil loss through anti filtration function. At the same time, the reinforcement performance is used to disperse lateral pressure and avoid cracks and tilting of the wall due to long-term compression.

2. Reinforced earth retaining wall engineering: As one of the core "reinforcement materials" of reinforced earth retaining walls, it is layered and laid in backfill soil to form a composite reinforced structure with the soil, greatly improving the overall shear strength of backfill soil, adapting to scenarios such as highways and railway slopes that require high bearing capacity, reducing the size of retaining walls, and lowering engineering costs.

3. Cantilever/buttressed retaining wall engineering: In the backfill area of reinforced concrete cantilever and buttressed retaining walls (mostly used in large parking lots and industrial parks), it is laid near the toe and heel of the wall to isolate the backfill soil from the wall foundation, prevent fine soil particles from blocking the foundation drainage holes, and protect the wall reinforcement from soil corrosion.

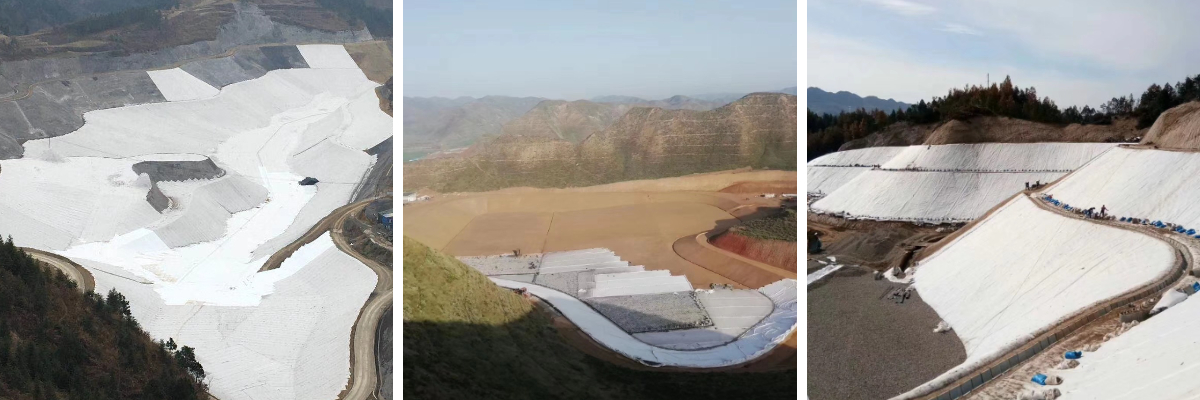

4. Ecological retaining wall engineering: In ecological retaining walls such as grass planting concrete and ecological gabion, they are laid between ecological materials and backfill soil, ensuring soil stability through anti filtration function and preventing soil erosion from affecting vegetation growth; It can also prevent the pores of ecological materials from being blocked by fine soil, maintain the ecological permeability of retaining walls, and adapt to ecological scenes such as urban rivers and wetland parks.

The Geotech Fabric for Retaining Walls has the core advantages of "reinforced compression resistance, anti filtration soil stabilization, isolation protection, and adaptability for easy construction", accurately targeting the structural stability and long-term durability requirements of retaining wall engineering. Whether it is the protection of traditional gravity retaining walls, the reinforcement of high demand reinforced soil retaining walls, or the functional adaptation of ecological retaining walls, it can provide reliable guarantees for engineering through scientific performance design - reducing safety hazards such as wall sliding and settlement, extending service life, and reducing maintenance costs. As the "invisible guardian" of retaining wall engineering, this product balances functionality and economy, and is an indispensable supporting material for improving the quality and optimizing efficiency of various retaining wall projects.