30 mil HDPE

1.Strong impermeability: Made of dense material and suitable thickness, effectively blocking liquid leakage.

2.Durable and durable: Resistant to tension, wear, tear, adapt to base deformation, with a lifespan of up to decades.

3.Corrosion and weather resistance: Resistant to acid and alkali corrosion, UV and high/low temperature, strong environmental adaptability.

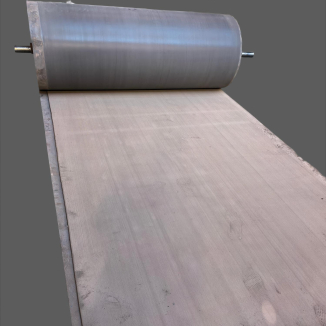

4.Construction worry free: Can be welded into a whole, with firm joints, suitable for complex terrains, and convenient and reliable construction.

Product Introduction

1、 Basic attributes

Material and specifications:30 mil HDPE is used as the core anti-seepage layer laid at the bottom and slopes of the landfill area to prevent leachate from seeping into the soil and groundwater, while isolating the diffusion of landfill gas and protecting the surrounding ecological environment.

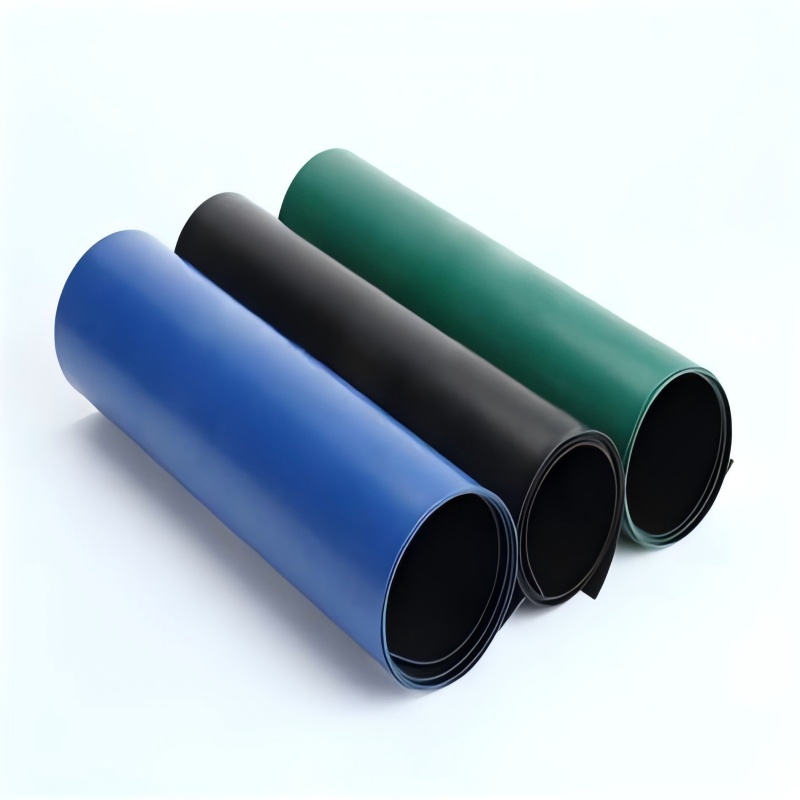

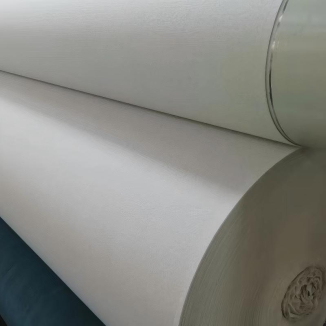

Physical characteristics: The appearance is a flexible sheet material with high tensile strength, elongation at break, and puncture resistance. The texture is tough and bendable at room temperature, suitable for different laying conditions.

2、 Core functions

Anti leakage barrier: Through a dense molecular structure and suitable thickness, an efficient anti leakage barrier is formed to prevent the leakage of liquids (such as sewage, groundwater, chemical solutions) and gases. It is the core material for controlling leakage in engineering.

Structural protection: relying on mechanical performance support, reducing the damage to engineering structures caused by base settlement and external impact, while isolating soil, waste residue and other media to avoid the diffusion of pollutants.

3、 Main features

Strong durability: acid and alkali resistant, corrosion-resistant, able to resist chemical erosion in soil or media; Anti UV aging, resistant to high and low temperatures (stable operation from -60 ℃ to 60 ℃), with a service life of over 50 years.

Good construction adaptability: seamless splicing can be achieved through hot melt welding, with high joint strength and reliable sealing; The material is flexible and can adapt to irregular terrain for laying, making construction convenient and quality easy to control.

Widely applicable to scenarios with high requirements for anti-seepage and anti-corrosion, such as landfills, sewage treatment tanks, water conservancy projects, artificial lakes, etc., balancing long-term effectiveness and economy.

Product Parameters

Metric | ASTM | unit | Test value | Minimum test frequency | ||||||

test method | 0.75 mm | 1.00 mm | 1.25 mm | 1.50 mm | 2.00 mm | 2.50mm | 3.00 mm | |||

Minimum average thickness | D5199 | mm | 0.75 | 1 | 1.25 | 1.5 | 2 | 2.5 | 3 | Per volume |

Minimum value (any one of 10) | -10% | -10% | -10% | -10% | -10% | -10% | -10% | |||

minimum density | D 1505/D 792 | g/cm3 | 0.94 | 0.94 | 0.94 | 0.94 | 0.94 | 0.94 | 0.94 | 90,000 kg |

Minimum average tensile performance (1) | D638 Type IV | |||||||||

Breakage strength, | N/mm | 20 | 27 | 33 | 40 | 53 | 67 | 80 | 9,000 kg | |

yield strength | N/mm | 11 | 15 | 18 | 22 | 29 | 37 | 44 | ||

Strain extension, | % | 700 | 700 | 700 | 700 | 700 | 700 | 700 | ||

yield extension | % | 12 | 12 | 12 | 12 | 12 | 12 | 12 | ||

Minimum strength of right-angle tear | D 1004 | N | 93 | 125 | 156 | 187 | 249 | 311 | 374 | 20,000 kg |

Minimum puncture strength | D4833 | N | 240 | 320 | 400 | 480 | 640 | 800 | 960 | 20,000 kg |

Constant tensile load stress cracking (2) | D5397 | hour | 300 | 300 | 300 | 300 | 300 | 300 | 300 | Based on GRI GM-10 |

Carbon black content | D 1603(3) | % | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 9,000 kg |

Carbon black dispersion | D5596 | Note (4) | Note (4) | Note (4) | Note (4) | Note (4) | Note (4) | Note (4) | 20,000 kg | |

Oxygen induction time (OIT) (5) | 90,000 kg | |||||||||

(a) Standard OIT | D3895 | minute | 100 | 100 | 100 | 100 | 100 | 100 | 100 | |

(b) high-handed OIT | D5885 | minute | 400 | 400 | 400 | 400 | 400 | 400 | 400 | |

85℃ Oven aging (minimum average) (5)(6) | Per formula | |||||||||

(A) Standard OIT is retained after 90 days | D 5721 | % | 55 | 55 | 55 | 55 | 55 | 55 | 55 | |

(B) High voltage OIT is retained for 90 days | D 3895 D5885 | % | 80 | 80 | 80 | 80 | 80 | 80 | 80 | |

Ultraviolet resistance (7) | Per formula | |||||||||

(a) standard OIT | D3895 | Note (8) 50 | ||||||||

(b) Retention of high pressure OIT after 1600 hours (9) | D5885 | % | ||||||||

Product Application

1、 Environmental engineering field

Landfill site: As the core anti-seepage layer, it is laid at the bottom and slope of the landfill area to prevent the infiltration of leachate into the soil and groundwater, while isolating the diffusion of landfill gas and protecting the surrounding ecological environment.

Hazardous waste disposal site: for the isolation and treatment of toxic and harmful waste residues and liquids, relying on chemical corrosion resistance to prevent pollutant leakage and soil or water source pollution.

Sewage treatment and leachate treatment tank: used as an anti-seepage lining for treatment tanks and regulating tanks to prevent sewage and sludge leakage and ensure stable operation of the treatment system.

2、 Water conservancy and civil engineering fields

Water conservancy anti-seepage engineering: such as anti-seepage treatment of artificial lakes, landscape water pools, reservoirs, and dams, reducing water leakage losses while protecting the stability of dam or slope structures.

Channel and Irrigation Engineering: Used as anti-seepage liners for irrigation channels and water pipelines to improve water resource utilization and reduce soil salinization caused by leakage.

Underground engineering waterproofing: used as a waterproof layer in subway, tunnel, underground pipe gallery and other projects to block groundwater infiltration and protect structural safety.

3、 Industrial and Special Engineering Fields

Industrial wastewater tanks and storage tank areas: Wastewater treatment tanks and acid alkali storage tanks in industries such as chemical, metallurgical, and pharmaceutical industries are anti-seepage, resistant to corrosive media erosion, and prevent leakage pollution.

Tailings pond and waste disposal yard: The bottom of mining tailings pond and industrial waste disposal yard is impermeable to prevent heavy metal ions and harmful solutions from infiltrating the soil, reducing environmental risks.

4、 In the field of agriculture and ecological restoration

Aquaculture pond: used for anti-seepage of fish ponds, shrimp ponds and other aquaculture facilities, reducing water leakage, and isolating harmful components in the soil to ensure stable aquaculture environment.

Ecological wetland and polluted site restoration: constructing anti-seepage foundation in wetland engineering to prevent sewage infiltration and diffusion; As an isolation layer in soil pollution remediation, it controls the migration of pollutants.

Its core application value lies in providing long-term and reliable environmental barriers for various projects through efficient anti-seepage, corrosion resistance, and weather resistance, while balancing engineering safety and ecological environmental protection needs. In summary, 30 mil HDPE geomembrane has become the core material for anti-seepage engineering in various fields such as environmental protection, water conservancy, industry, and agriculture due to its strong anti-seepage ability, stable chemical properties, and wide environmental adaptability. Whether it is controlling the spread of pollutants, reducing water resource loss, or ensuring the safety of engineering structures, it can play a key role through long-term stable performance, providing solid guarantees for the ecological protection and long-term operation of various projects.