Driveway Geocell

1.Enhance the bearing capacity of the subgrade

The grid formed by the cell exerts a "lateral confinement effect" on the filling material, dispersing the vehicle load onto a larger area of the subgrade and reducing local stress concentration (similar to the mechanical stability of a honeycomb structure).

2.Prevent subgrade deformation and settlement

The three - dimensional structure restricts the lateral movement of soil particles, inhibits the plastic deformation of the subgrade under repeated vehicle loads, and is especially suitable for handling uneven settlement problems

3.Optimize drainage and anti-erosion performance

The gaps between the cells can form drainage channels, accelerating the discharge of subgrade moisture and reducing the softening effect of water on the subgrade. At the same time, the filling materials (such as graded sand and gravel) can resist rainwater erosion under the constraint of the cells, protecting the slope.

Product Introduction:

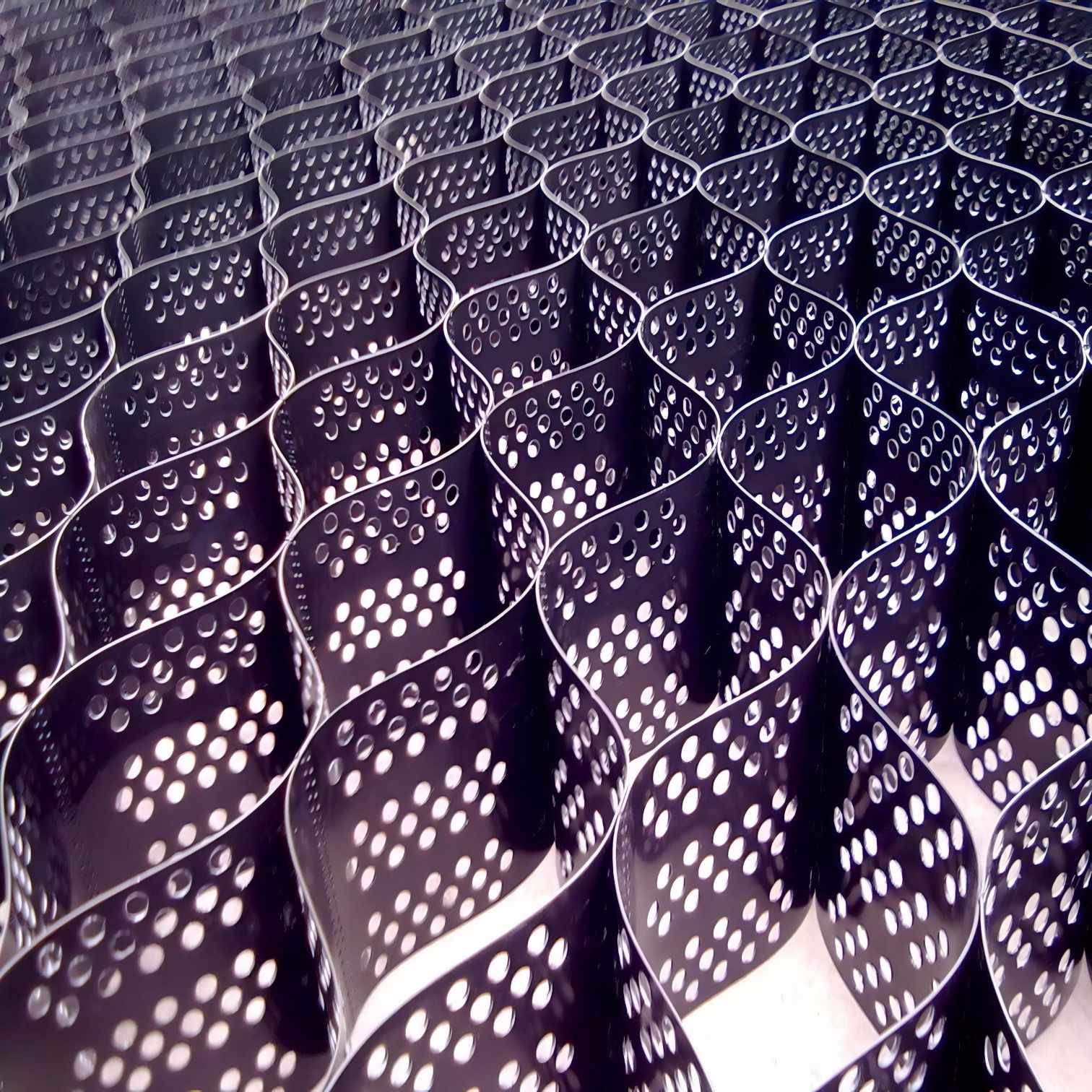

Driveway Geocell is a geosynthetic material used in road engineering. Its structure and function are similar to those of high - density polyethylene (HDPE) geocell. It gets its name because it forms a three - dimensional grid structure resembling a honeycomb when unfolded.

Principle of operation

Lateral restraint effect: When the geocell is filled with soil and stone materials, the interface friction coefficient between the cell wall and the filler can reach 0.8 - 1.2. Combined with the deformation self - adaptive characteristics of the honeycomb structure, multi - level stress diffusion layers can be formed in the subgrade, effectively restricting the lateral displacement of soil particles, forming a "grid locking" mechanism, and significantly enhancing the integrity of the subgrade structure.

Stress Diffusion: The spatial segmentation of honeycomb units fundamentally changes the load transfer path. The vertical stress is evenly diffused to the surrounding soil through the cell walls, forming a multi-directional stress balance system. Under dynamic load scenarios, this three-dimensional constraint system can absorb approximately 30% of the impact energy, avoiding local damage caused by stress concentration.

Product Parameters:

order number | raw and processed material | |||||||

test item | unit | polytene | sulan | polyester | ||||

Extruded type | Stretch type | Extruded type | Stretch type | Extruded type | Stretch type | |||

1 | tensile strength | kN/m | ≥20 | ≥100 | ≥23 | ≥100 | ≥30 | ≥120 |

2 | Tensile yield strain | % | ≤15 | — | ≤15 | — | ≤15 | - |

3 | Tensile fracture strain | % | — | 8~ 20 | — | 6~ 15 | — | 8~ 20 |

4 | Carbon black content a | % | 2. 0~ 3. 0 | |||||

5 | Carbon black dispersion a | — | There should be no more than one level 3 data item in ten data items and no level 4 or 5 data items | |||||

6 | 200℃ oxidation induction time | min | ≥20 | ≥20 | — | |||

7 | Tensile load stress cracking | h | ≥300 | — | ||||

8 | B. Resistance to artificial climate aging retention rateb | % | ≥80 | |||||

9 | Chemical resistance performance retention rate c | % | — | ≥80 | ||||

Product Applications:

1.Highway and Urban Road Construction

Subgrade Treatment for Newly-built Roads: Lay cellular confinement systems on soft foundations (such as silty clay and collapsible loess) to enhance subgrade stability and reduce construction costs (compared with the traditional replacement method, the amount of earthwork can be reduced).

Renovation and Maintenance of Existing Roads: It is used to repair subgrade settlement, ruts and other diseases. There is no need for large - scale excavation. Directly lay cellular confinement systems on the damaged sections and fill them with aggregates to quickly restore the road performance.

2.Heavy - loaded Traffic and Special Road Sections

Roads in Industrial Parks and Logistics Parks: Subject to frequent rolling by heavy - duty trucks, the cellular confinement system can enhance the anti - deformation ability of the roadbed and extend the service life of the road.

Treatment of Bump at Bridgehead: Lay the cellular confinement system at the connection between the abutment and the roadbed to relieve the settlement difference caused by the stiffness difference and reduce the bumping phenomenon.

3.Slope and Embankment Protection

Embankment Slope Reinforcement: After filling the geocell with soil, vegetation can be planted to form an ecological protection system of "geocell + vegetation", which not only stabilizes the slope but also beautifies the environment.

Roads in Desert and Gobi Areas: Resist wind and sand erosion, prevent the subgrade filling from being eroded by wind or washed away by rainwater, and maintain the road shape.

4.Temporary Roads and Emergency Projects

The quickly installable honeycomb cellular temporary road is suitable for construction access roads, disaster relief passages, etc. It has the characteristics of convenient disassembly and assembly and reusable.

The lane honeycomb cell achieves efficient reinforcement of the roadbed through the lateral confinement of the three - dimensional honeycomb structure. It has the characteristics of convenient construction and strong adaptability, and is particularly suitable for solving engineering problems such as soft foundations, settlement diseases, and slope protection. It is one of the important materials for improving the performance of roadbeds in modern road engineering.